Portable sensor clamp applied to smart reinforcing steel bars

A sensor and steel bar technology, applied in instruments, scientific instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of increasing the difficulty of cutting and pasting sensors, inability to achieve non-destructive monitoring, and inability to achieve large-scale implementation, and reduce the production burden. , Easy installation, high operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

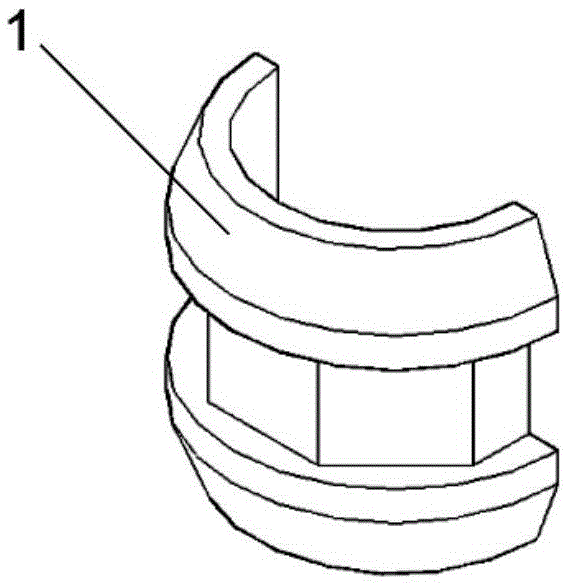

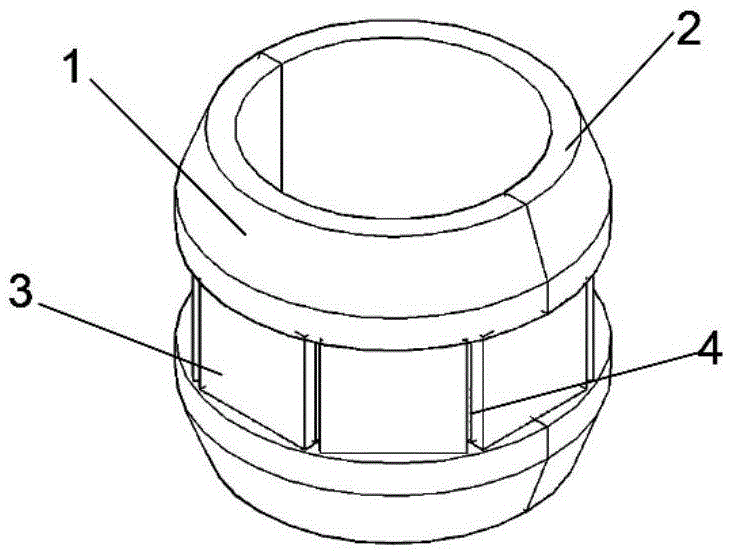

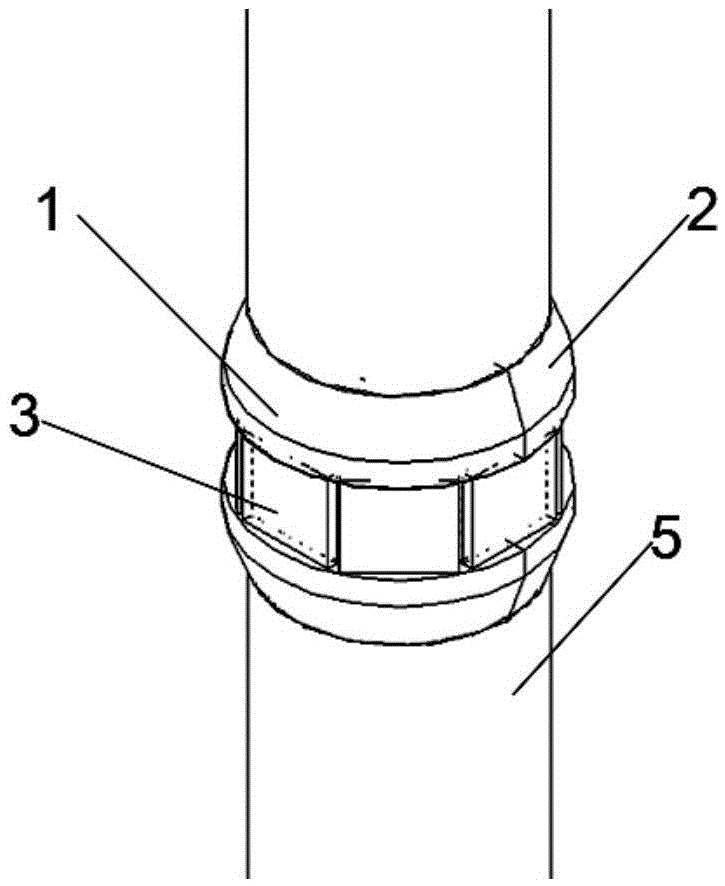

[0025] Such as Figure 1-2 As shown, a portable sensor fixture applied to smart steel bar, including clamping part 1, clamping part 2, piezoelectric ceramic crystal sensor 3, silver-containing epoxy resin 4, wherein: clamping part 1, clamping part 2 Spliced together to form a cylindrical structure, the central part of the cylindrical structure is a cylindrical shape, used to fit the steel bar 5 completely; the middle section of the cylindrical structure is a regular octagon, with eight piezoelec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com