Ice cream machine

An ice cream machine and cylinder technology, applied in refrigerators, frozen desserts, fluid circulation arrangements, etc., can solve problems such as difficulty in achieving orderly flow, mutual influence of refrigerant flows, and difficulty in forming closed flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

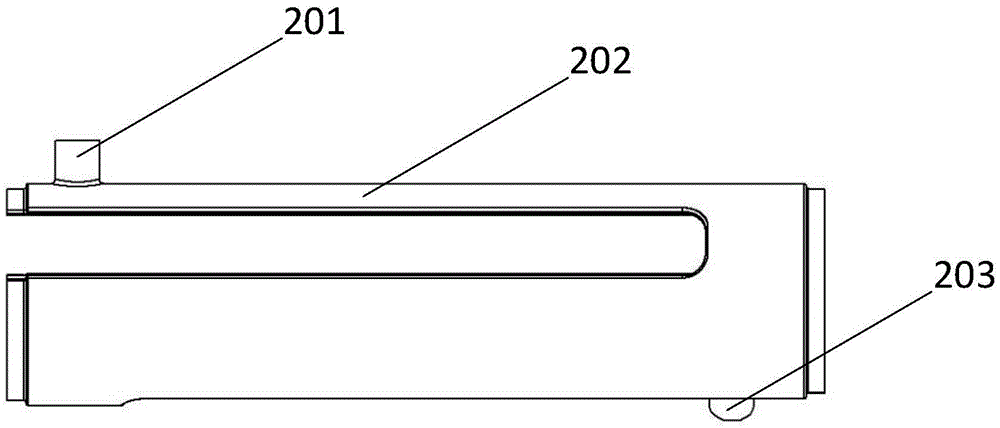

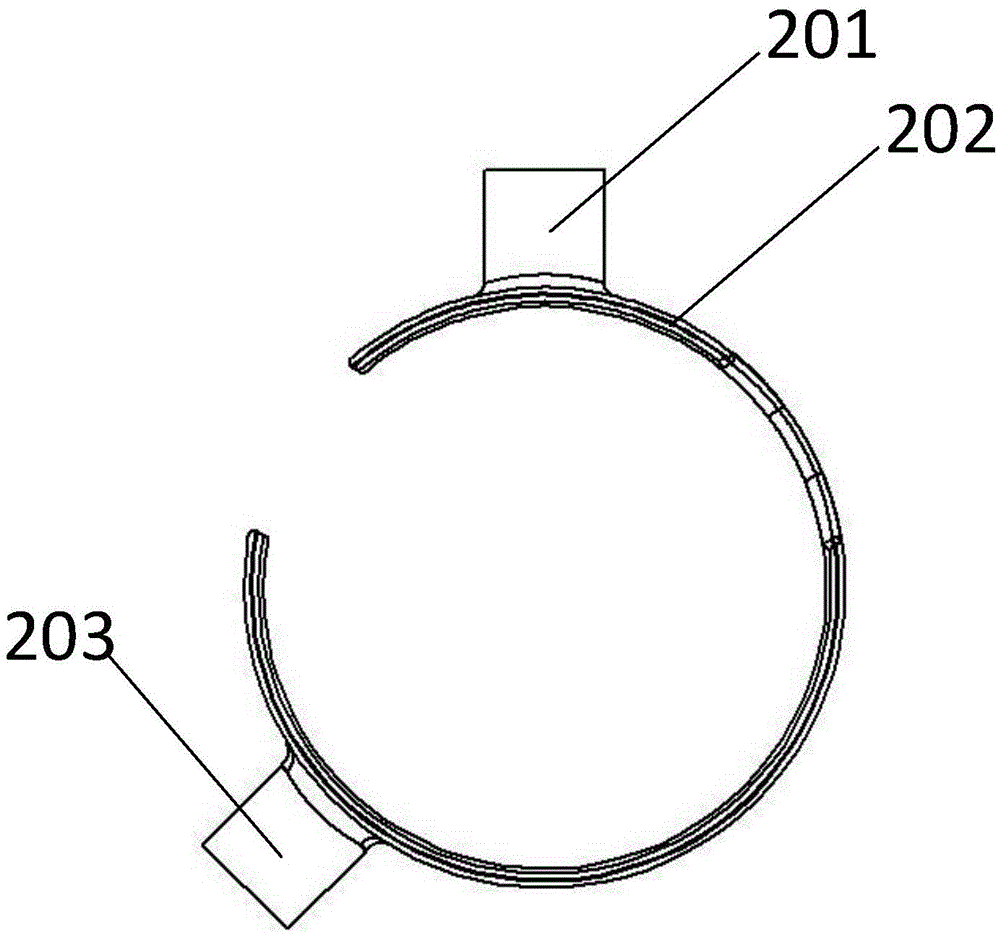

[0028] Figure 1 to Figure 5 A first embodiment of the invention is shown. Figure 6 to Figure 7 A second embodiment of the invention is shown.

[0029] First, the first embodiment of the present invention will be described in detail.

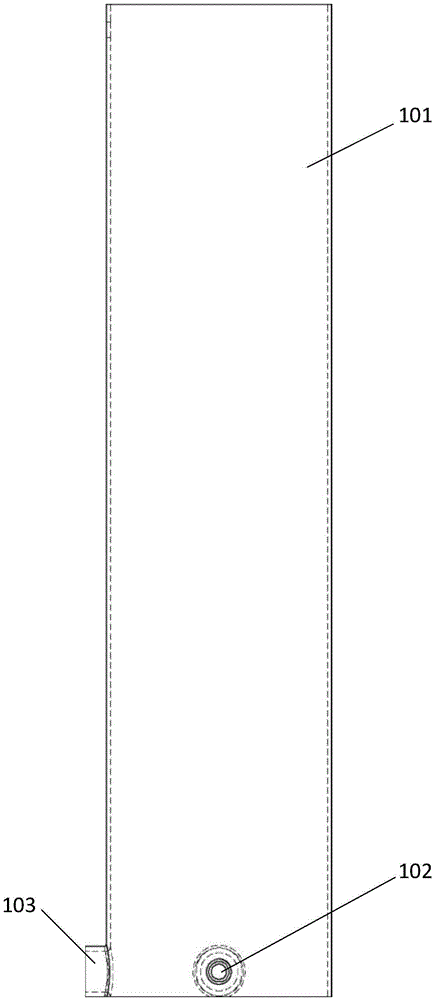

[0030] figure 1 shows the structure of the refrigeration cylinder, including the cylinder wall of the cylindrical cylinder (in figure 1 Observed in the cylinder wall facing the outside of the refrigeration cylinder outer wall 101), the material inlet 102 and the pressure transmitter interface 103. figure 1 Among them, the material inlet 102 and the pressure transmitter interface 103 are arranged adjacent to the lower end of the refrigeration cylinder. The material enters the refrigeration cylinder from the material inlet 102, and at the same time, the pressure transmitter applies pressure to the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com