Special-shaped-cross-section hot-rolled steel plate coil and manufacturing method thereof

A hot-rolled steel plate, cross-section technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of unreasonable, insufficient welding thickness at both ends of U-ribbed steel, and cracked structural strength of cold-formed corner welds. and other problems to achieve the effect of reducing secondary welding, improving the safety of welded structures, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

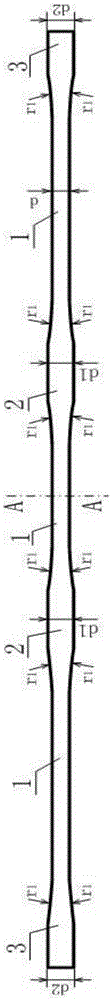

[0058] A special-shaped cross-section hot-rolled steel plate coil, which is composed of a base plate 1, a central double-sided thickening zone 2, an end double-sided thickening zone 3, and an inner arc r1, and its longitudinal length can reach 350 meters. The central bilateral thickened region 3 is horizontally connected by the substrate 1 to form a whole, and the inner arc r1 is used for a smooth transition between the central bilateral thickened region 2 and the end bilateral thickened region 3 and the substrate 1 . Such as figure 1 shown.

[0059] The central double-sided thickened region 2 is symmetrically located on both sides of the centerline AA of the substrate (1), and the central double-sided thickened region 2 and the substrate 1 are connected together through a smooth transition of the inner arc r1.

[0060] The distance between the centerlines of the two central bilateral thickening zones 2 is 150mm.

[0061] The end double-sided thickened regions 3 are symmetri...

Embodiment 2

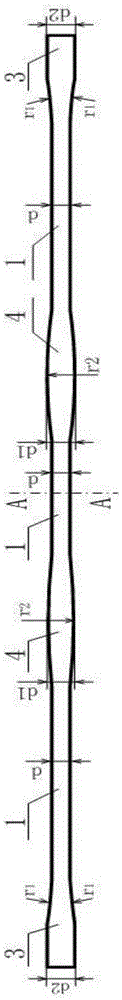

[0068] Others are the same as embodiment 1, the difference is:

[0069] Special-shaped cross-section hot-rolled steel plate coil, composed of base plate 1, central double-sided thickened zone 2, end double-sided thickened zone 3 and inner arc r1, its longitudinal length can reach 450 meters; two central double-sided thickened zones 2 centerline The distance between them is 250mm.

[0070] The thickness d of the substrate is 7 mm; the thickness d1 of the middle double-sided thickened region 2 is 8 mm; the thickness d2 of the double-sided thickened region 3 at the end is 10 mm.

[0071] Its cross section: the length of the bilateral thickened region 3 at the end is 30 mm; its cross section: the length of the bilateral thickened region 2 in the middle is 100 mm.

Embodiment 3

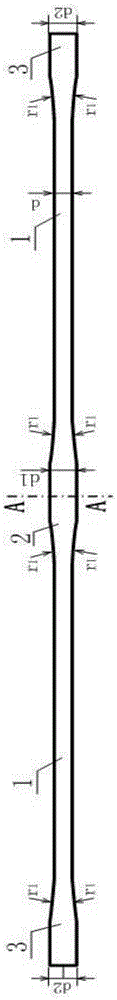

[0073] Others are the same as embodiment 1, the difference is:

[0074] Special-shaped cross-section hot-rolled steel plate coil, composed of base plate 1, central double-sided thickened zone 2, end double-sided thickened zone 3 and inner arc r1, its longitudinal length can reach 550 meters; two central double-sided thickened zones 2 centerline The distance between them is 480mm.

[0075] The thickness d of the substrate is 20 mm; the thickness d1 of the middle double-sided thickened region 2 is 22 mm; the thickness d2 of the end double-sided thickened region 3 is 26 mm.

[0076] Its cross section: the length of the bilateral thickened region 3 at the end is 50 mm; its cross section: the length of the bilateral thickened region 2 in the middle is 80 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com