A piston, a compressor having the same and a processing method for the piston

A processing method and piston technology, which is applied in mechanical equipment, machines/engines, liquid displacement machinery, etc., can solve the problems of increasing the total lateral force of the piston, hindering the performance of the compressor, and limited effect, so as to reduce the lateral force. Effects of Friction and Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

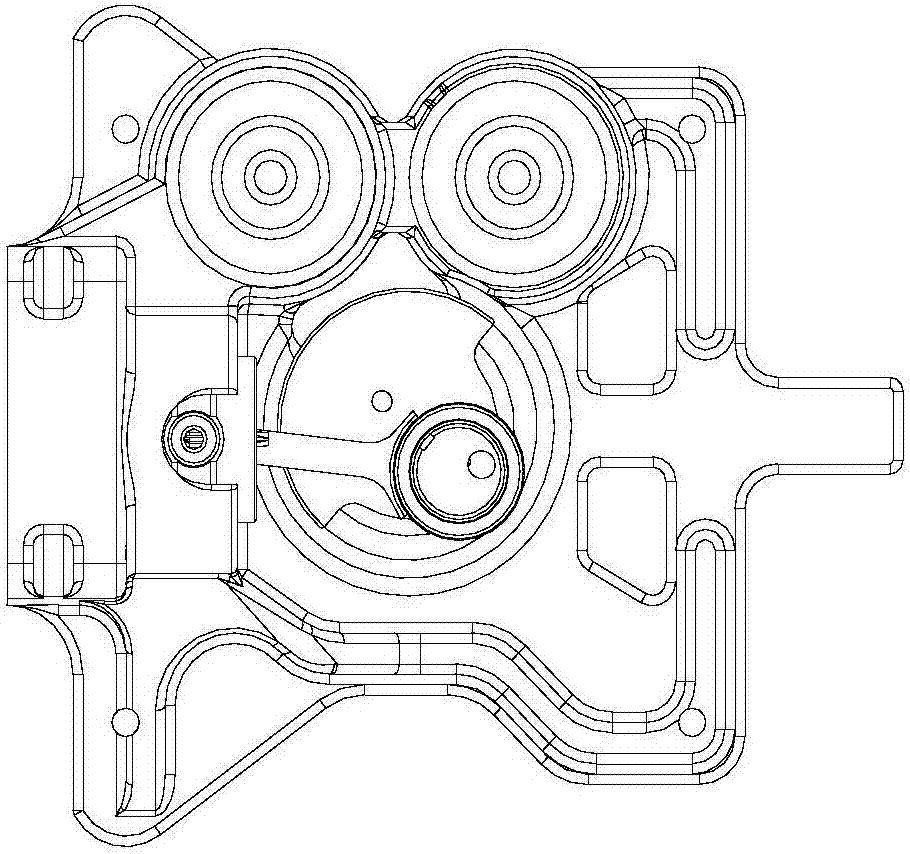

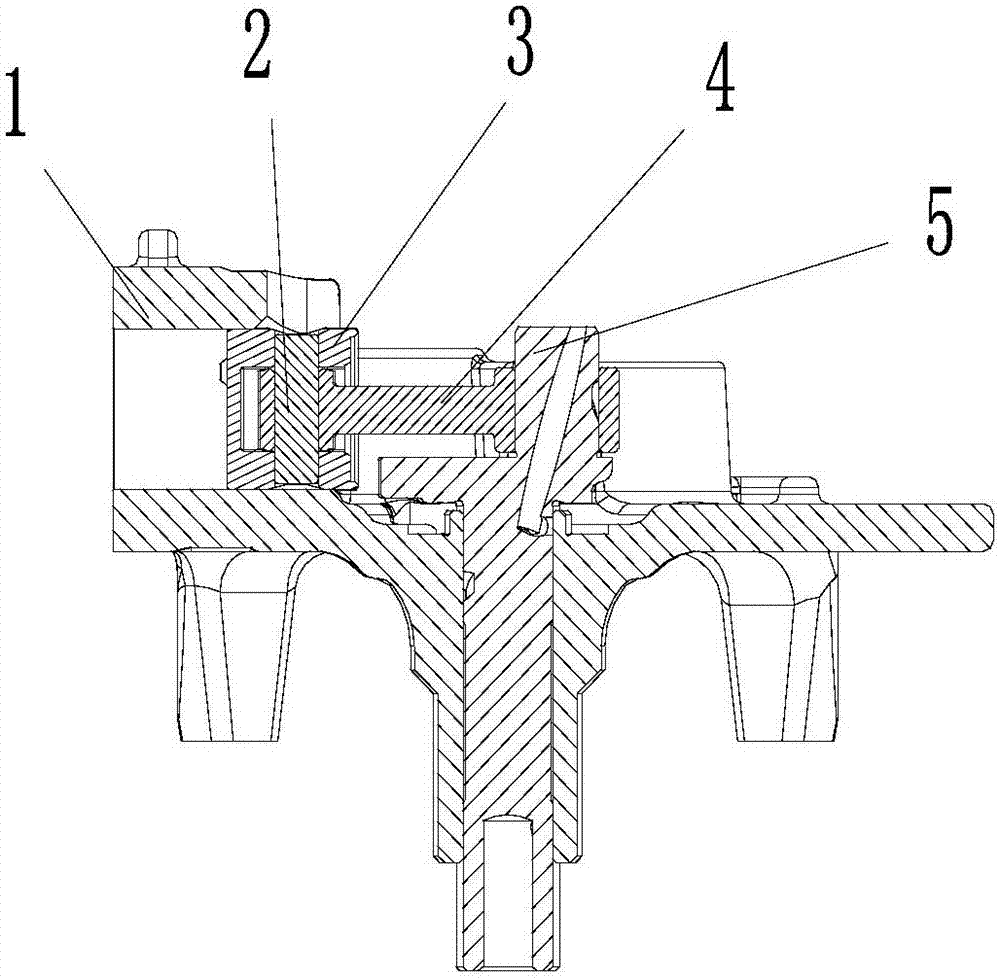

[0037] The present invention provides a kind of piston in view of the foregoing status of the prior art, which includes a piston body 6, see Figure 5-9 , the outer peripheral surface of the piston body 6 is provided with a groove, and the groove includes a first groove segment 8 and a second groove segment 9 . Wherein, the first slot section 8 is located on one side of the first central plane of the piston body, and the second slot section 9 is located on the other side of the first central plane. In particular, the area of the second groove segment 9 is larger than the area of the first groove segment 8 . Here, the area of the groove section may refer to the area defined by the outer edge of the groove on the outer peripheral surface of the piston body, or may refer to the projected area of the groove on the first central plane. In the present invention, the first center plane is a plane passing through the axis of the piston body 6 .

[0038] That is, the grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com