Circular pipe column and H-shaped beam connection structure

A technology for connecting structures and round pipes, applied in building structures, buildings, etc., can solve problems such as complex connections, avoid welding seam crossing, avoid stress concentration and metal fatigue, and facilitate construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

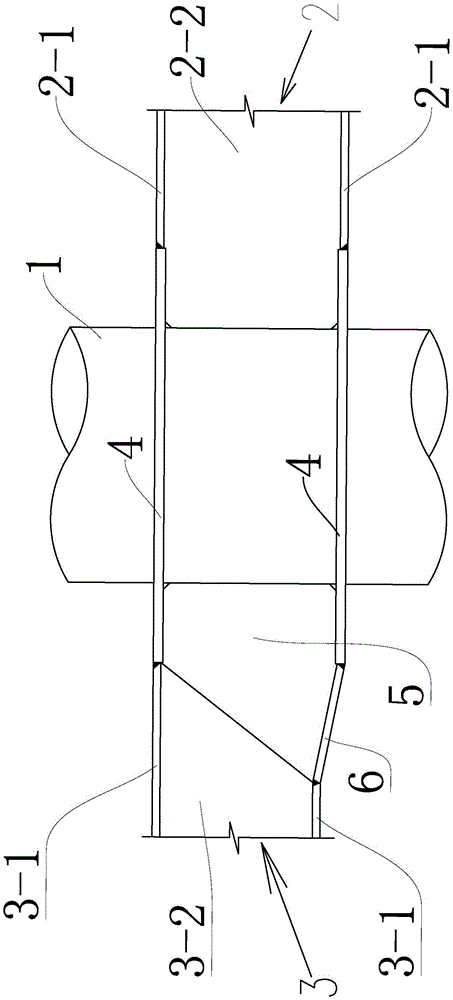

[0024] Such as figure 1 , figure 2 As shown, this example is applicable to large-diameter circular tubular columns, including vertical circular tubular column 1 and horizontal H-shaped beams on both sides of the column. In this example, there are beams I2 and beam II3, and the height of beam I2 is greater than that of beam II3. The connection between the column and the beam is through the connecting plate 4 (namely, the node member). The connecting plate 4 in this example is basically a ring plate, and the two sides are cut into straight lines. The installation position of the connecting plate 4 is the same as that of the wing The specific method is: the flange 2-1 of the beam I2 is partially cut off and then welded to the connecting plate 4 (that is, the connecting plate replaces part of the flange), and the web 2-2 of the beam I extends into the upper and lower two sides. Between the block connecting plates 4 and directly welded with the outer wall of the round pipe column...

Embodiment 2

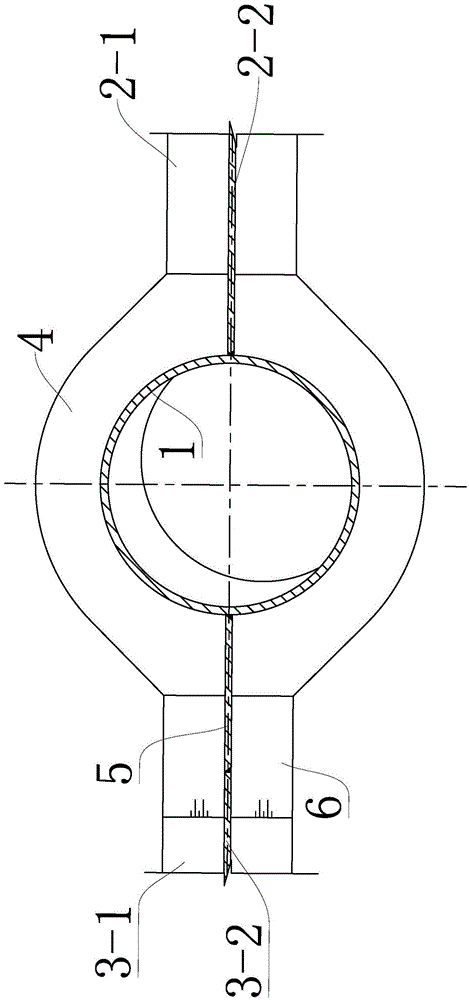

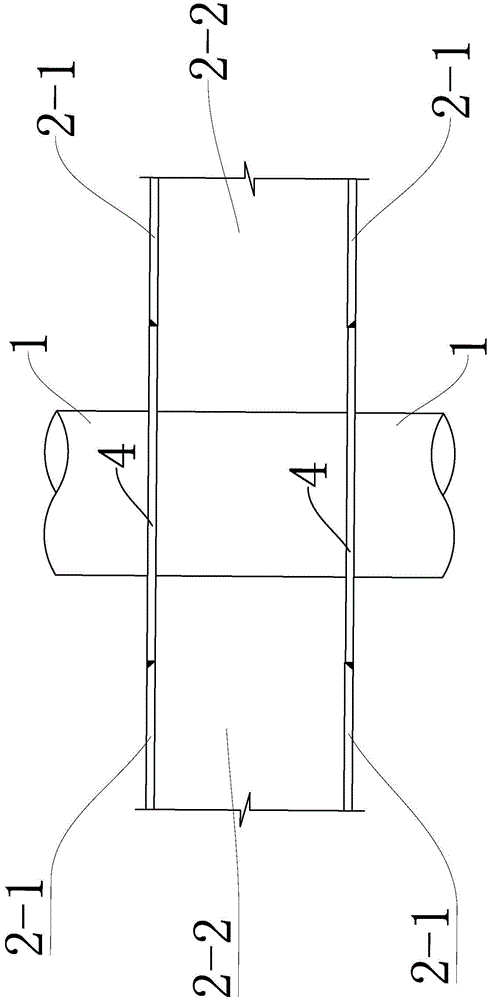

[0028] Such as image 3 , Figure 4 As shown, this example is suitable for small-diameter circular pipe columns, and the H-beams on both sides of the circular pipe column 1 are beam I2 (beam heights are equal). The connecting plate 4 is a flat plate (octagonal in this example) symmetrical on both sides, with a round hole matching the outer wall of the circular pipe column 1 left in the middle, and the installation position of the connecting plate 4 is the same as that of the two flanges 2-2 of the beam I. Corresponding to 1, the specific method is: the flange 2-1 of the beam I is partially cut off and then welded to the connecting plate 4, and the web 2-2 of the beam I extends vertically between the upper and lower connecting plates 4 and is on the central axis Butt welding at the place is firm, and two semicircular columns 1-1 are spliced and welded into a complete circular tube column 1 at the center of the connecting plate 4 and symmetrically on both sides of the web 2-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com