Three-dimensional braided composite material mechanical arm and manufacturing method thereof

A technology of three-dimensional weaving and composite materials, which is applied in the field of three-dimensional weaving composite material manipulators and its preparation, can solve the problems of weak mechanical properties between layers of fiber-reinforced braids, influence of manipulator amplitude on operation accuracy, and damage to composite material layers, etc., to achieve Good mechanical processing technology, strong design, and the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

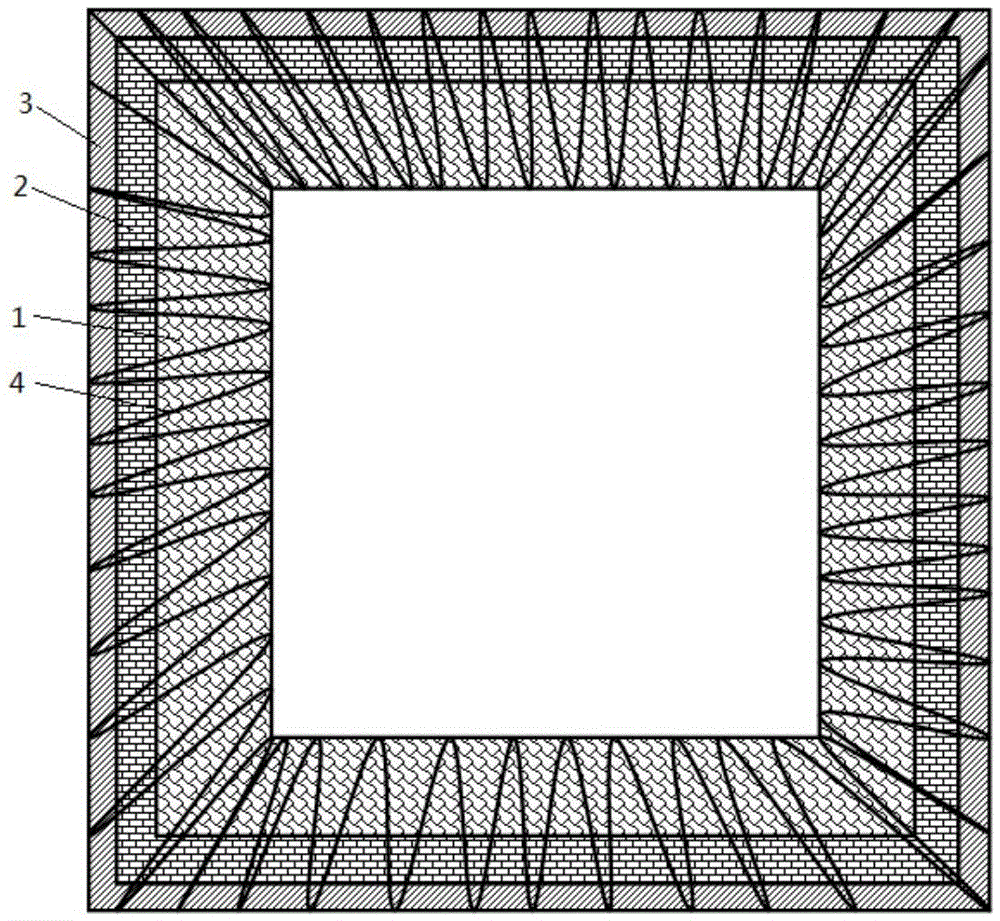

[0054] A three-dimensional braided composite material mechanical arm, the mechanical arm includes a main body rigid structure layer 1, an impact-resistant layer 2 and a surface machining assembly layer 3 from inside to outside; wherein, the main body rigid structure layer 1 includes a high modulus A three-dimensional braided structure made of fibers and a resin layer (or resin structure) impregnated and cured on the three-dimensional braided structure; A three-dimensional braided structure and a resin layer impregnated and cured on the three-dimensional braided structure; the surface mechanical processing assembly layer 3 includes a two-dimensional wound laminated fabric structure made of high-strength fibers and a two-dimensional wound laminated fabric impregnated and cured on the two-dimensional wound laminated fabric The resin layer (or resin structure) on the structure; the mechanical arm also includes: a secondary fiber seam-laying structure that sews the three layers of t...

Embodiment 2

[0062] A three-dimensional braided composite material mechanical arm, the mechanical arm includes a main body rigid structure layer 1, an impact-resistant layer 2 and a surface machining assembly layer 3 from inside to outside; wherein, the main body rigid structure layer 1 includes a high modulus A three-dimensional braided structure made of fibers and a resin layer impregnated and cured on the three-dimensional braided structure; A resin layer cured on the three-dimensional braided structure; the surface machining assembly layer 3 includes a two-dimensional wound laminated fabric structure made of high-strength fibers and a resin layer impregnated and cured on the two-dimensional wound laminated fabric structure; The mechanical arm also includes: a secondary fiber seam-laying structure for sewing the three layers of the main body rigid structure layer 1 , the impact-resistant layer 2 and the surface machining assembly layer 3 .

[0063] A method for preparing a three-dimensi...

Embodiment 3

[0070] A three-dimensional braided composite material mechanical arm, the mechanical arm includes a main body rigid structure layer 1, an impact-resistant layer 2 and a surface machining assembly layer 3 from inside to outside; wherein, the main body rigid structure layer 1 includes a high modulus A three-dimensional braided structure made of fibers and a resin layer impregnated and cured on the three-dimensional braided structure; A resin layer cured on the three-dimensional braided structure; the surface machining assembly layer 3 includes a two-dimensional wound laminated fabric structure made of high-strength fibers and a resin layer impregnated and cured on the two-dimensional wound laminated fabric structure; The mechanical arm also includes: a secondary fiber seam-laying structure for sewing the three layers of the main body rigid structure layer 1 , the impact-resistant layer 2 and the surface machining assembly layer 3 .

[0071] A method for preparing a three-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com