Method of preparing trichloro-acetic chloride from silicon tetrachloride

A technology of trichloroacetyl chloride and silicon tetrachloride, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problem of refractory treatment of polysilicon and cost of by-product silicon tetrachloride trichloroacetyl chloride Advanced problems, to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

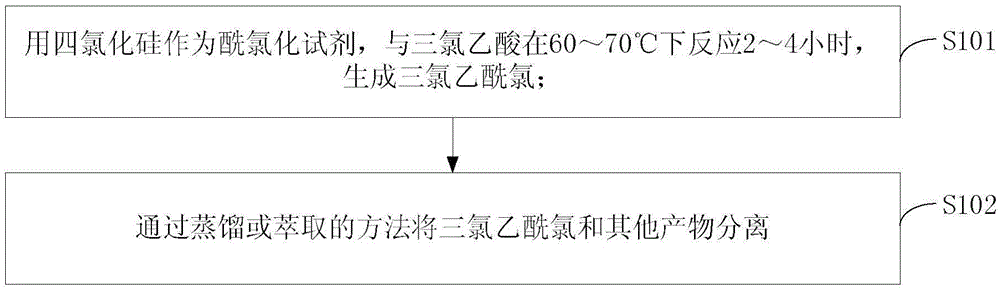

Method used

Image

Examples

Embodiment 1

[0029] Add a certain amount of trichloroacetic acid into an acid-resistant reaction kettle with a reflux and stirring device, add silicon tetrachloride at a molar ratio of 1:1.1, and react at 60°C for 4 hours. At the same time, excessive silicon tetrachloride and generated hydrogen chloride are recovered and treated.

[0030] Distill at 60-80°C, first distill off excess silicon tetrachloride. Raise the temperature and distill off trichloroacetyl chloride at 110-120°C.

Embodiment 2

[0032] Add a certain amount of trichloroacetic acid into an acid-resistant reaction kettle with a reflux and stirring device, add silicon tetrachloride at a molar ratio of 1:2.0, and react at 65°C for 3 hours. At the same time, excessive silicon tetrachloride and generated hydrogen chloride are recovered and processed.

[0033] Distill at 60-80°C, first distill off excess silicon tetrachloride. Raise the temperature and distill off trichloroacetyl chloride at 110-120°C.

Embodiment 3

[0035] Add a certain amount of trichloroacetic acid into an acid-resistant reaction kettle with a reflux and stirring device, add silicon tetrachloride at a molar ratio of 1:2.5, and react at 70°C for 2 hours. At the same time, excessive silicon tetrachloride and generated hydrogen chloride are recovered and processed.

[0036] Distill at 60-80°C, first distill off excess silicon tetrachloride. Raise the temperature and distill off trichloroacetyl chloride at 110-120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com