An evaporation system for wastewater treatment equipment

An evaporation system and wastewater treatment technology, which is applied in the field of environmental engineering, can solve the problems of slow evaporation rate, undisclosed evaporation system structure, and low evaporation efficiency of the evaporation system, so as to achieve the effects of not easy to lose, improve evaporation efficiency, and ensure smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

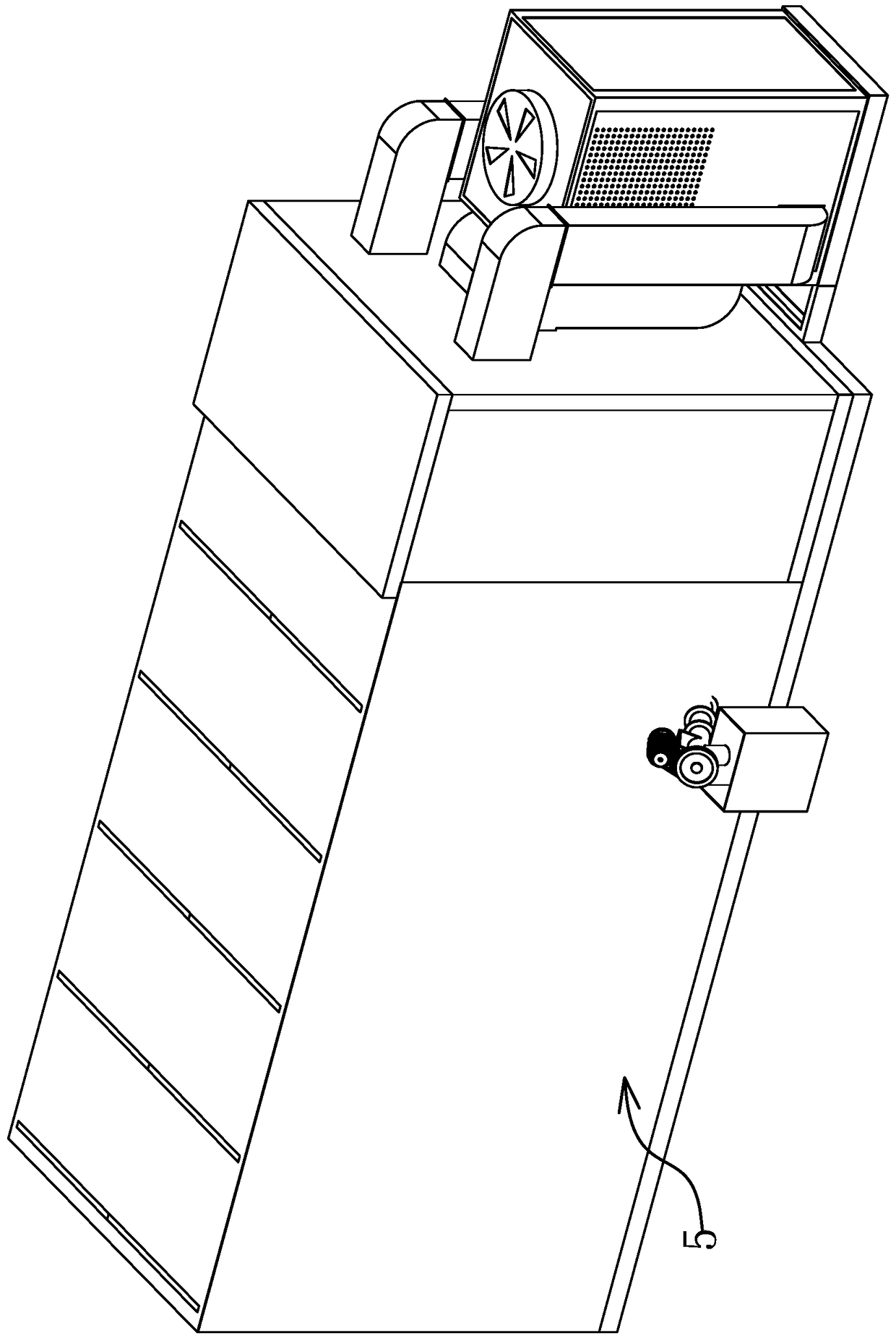

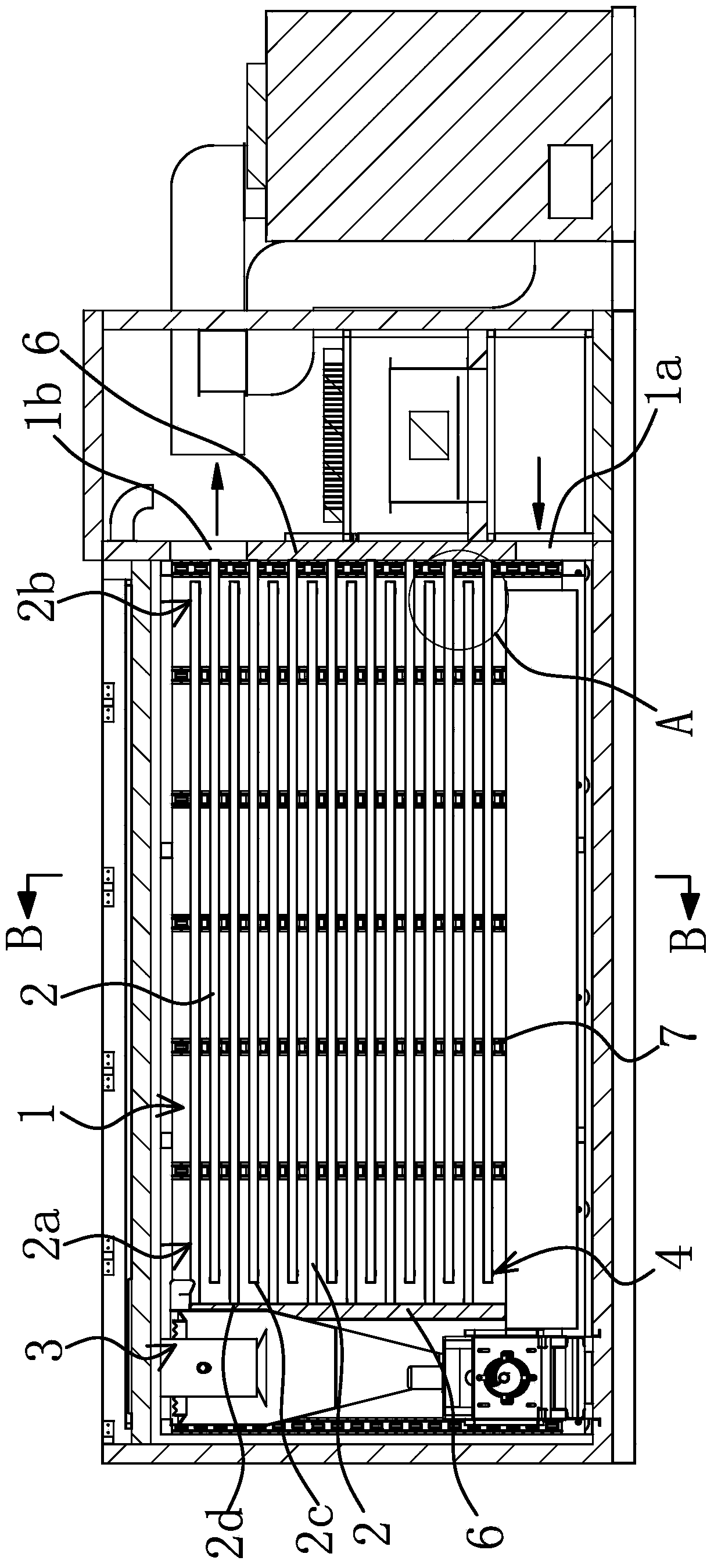

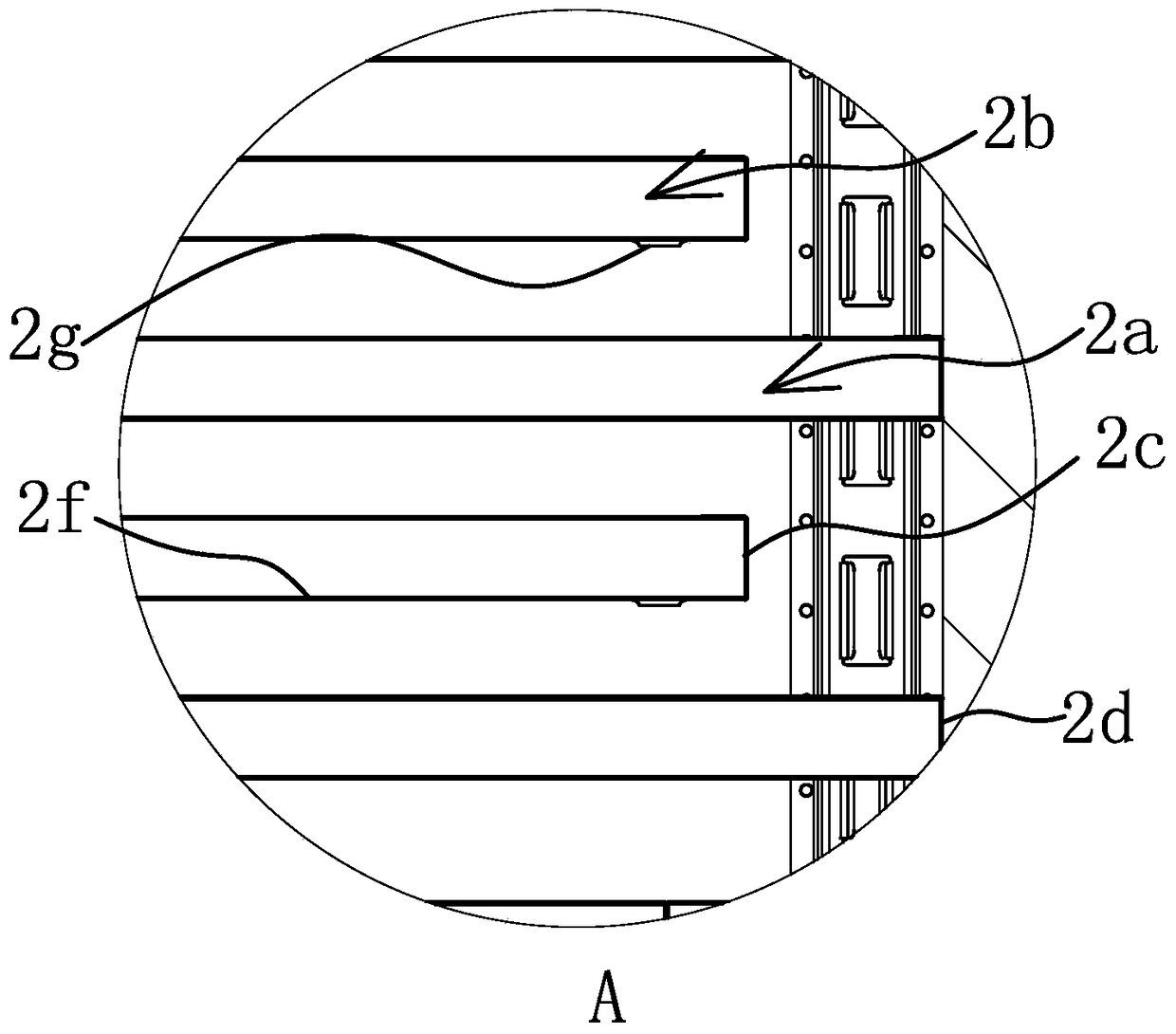

[0038] Such as Figure 1 to Figure 2 As shown, an evaporation system of wastewater treatment equipment, the wastewater treatment equipment 5 includes a closed evaporation chamber 1, the evaporation chamber 1 is provided with an air inlet 1a at the lower part and an air outlet 1b at the upper part, and several The layer is a plate-shaped diversion groove 2, of course, the number of diversion grooves 2 in each layer can be one or more, and the diversion groove 2 can guide the flow of waste water, and the present invention sets up stacked The diversion tank 2 has a large evaporation area, which effectively improves the evaporation efficiency. When the waste water enters the diversion tank 2, the hot air sent from the outside evaporates the water molecules in the waste liquid. The hot air enters from the bottom and discharges from the top, effectively utilizing the hot air from the The characteristic of flowing from low to high makes each layer of wastewater can effectively contac...

Embodiment 2

[0050] Such as Figure 12 , Figure 13 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the water inlet structure 3 includes a sprinkler pipe 3b fixedly connected to the evaporation chamber 1, and the side wall of the evaporation chamber 1 is provided with a water sprinkling pipe. The through hole through which the pipe 3b passes, and the sprinkler pipe 3b is provided with a number of uniformly arranged sprinkler holes 3b1 on the side facing the guide tank 2 . The water supply to the evaporation chamber 1 through the water sprinkling pipe 3b is convenient and fast, and the water sprinkling hole 3b1 is directly aligned with the diversion groove 2, effectively ensuring that the water flow evenly enters the diversion groove 2 for subsequent evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com