Oil supply device for engine

一种供应装置、发动机的技术,应用在发动机的润滑、发动机元件、机器/发动机等方向,能够解决驱动损耗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the drawings.

[0025]

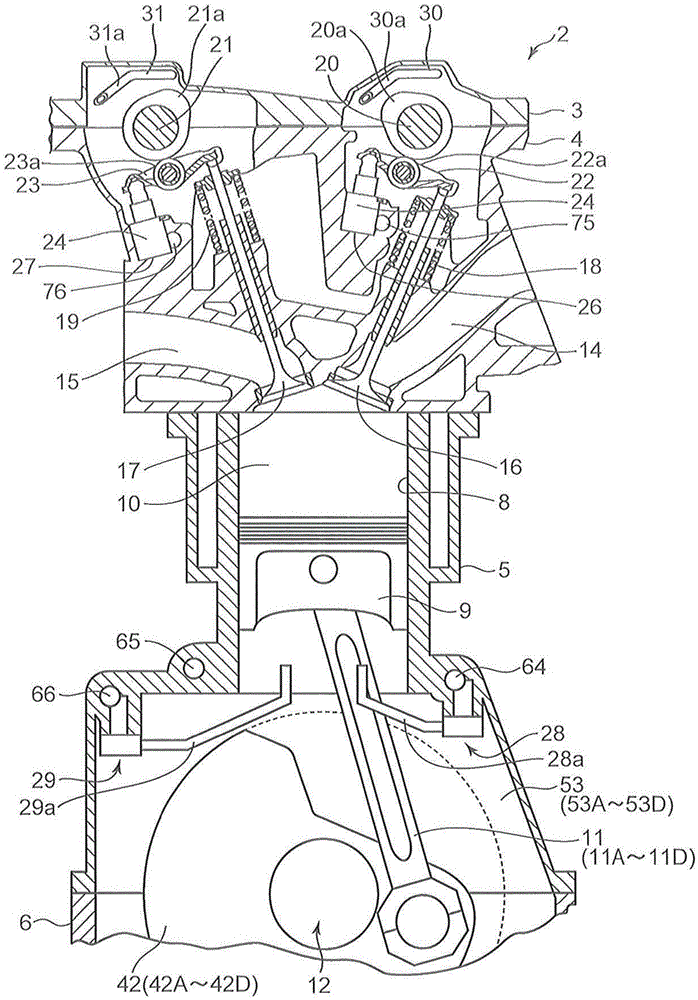

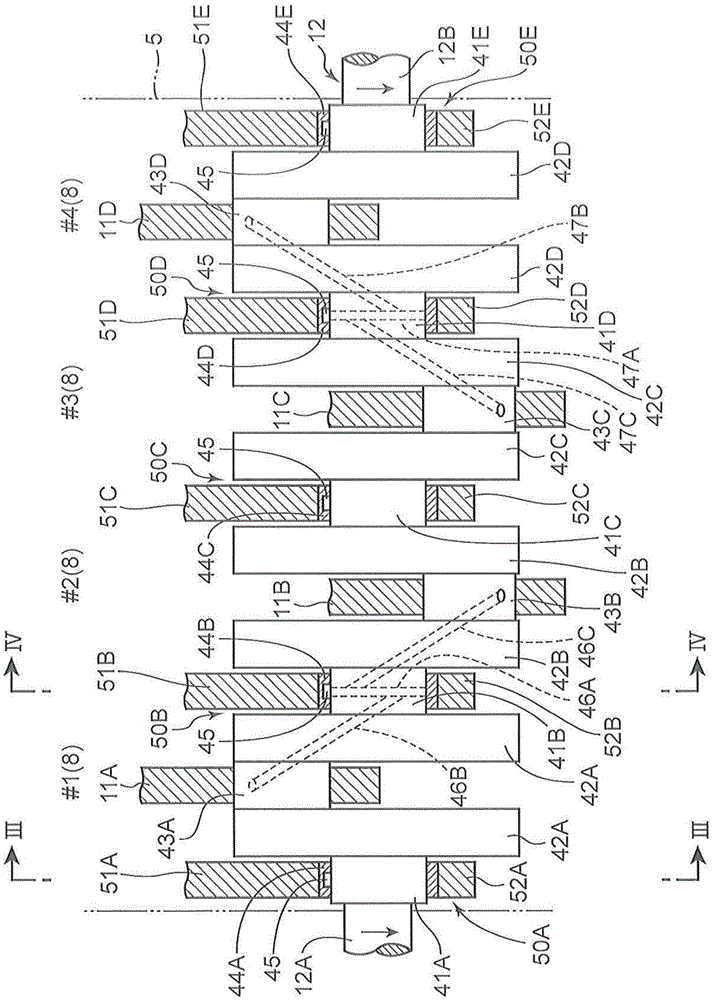

[0026] figure 1 A multi-cylinder engine 2 (hereinafter simply referred to as engine 2 ) to which the oil supply device according to the present invention is applied is shown. The engine 2 is the first cylinder #1 to the fourth cylinder #4 along with figure 1 In-line four-cylinder gasoline engines arranged in series in a direction perpendicular to the plane of the paper are mounted on vehicles such as automobiles.

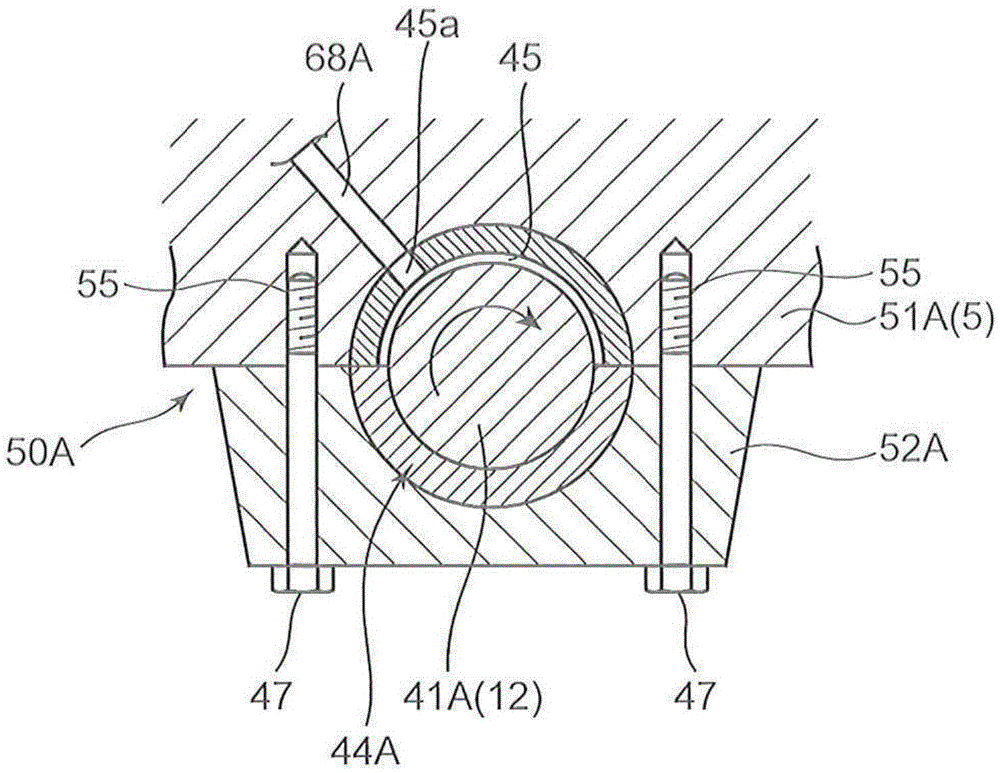

[0027] The engine 2 includes a camshaft cover 3 connected up and down, a cylinder head 4, a cylinder block 5, a crankcase 6 and an oil pan 7 (refer to Image 6 ). Four cylinder holes 8 are formed in the cylinder block 5, and a piston 9 is slidably accommodated in each cylinder hole 8, and a combustion chamber 10 is formed in each cylinder by the piston 9, the cylinder hole 8, and the cylinder head 4. . In addition, each pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com