Ultra-deep mine hoisting system multi-functional simulation test platform and experimental method

A technology for upgrading systems and simulation tests, applied to teaching models, educational tools, instruments, etc., can solve problems such as difficult testing of lifting equipment, and achieve the effects of small space occupation, compact equipment structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings.

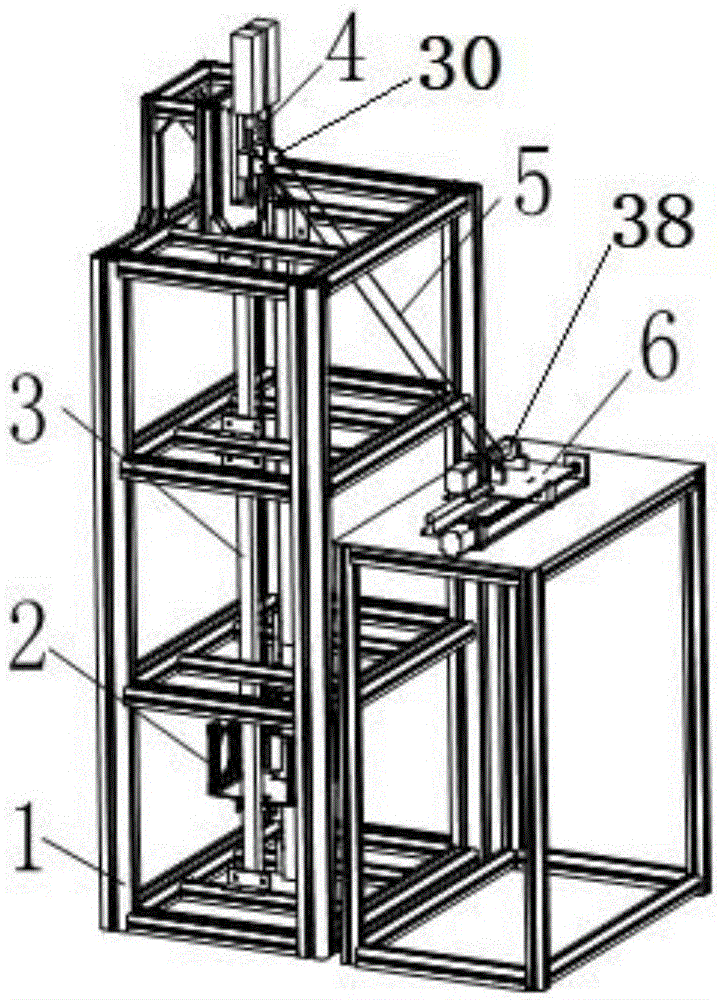

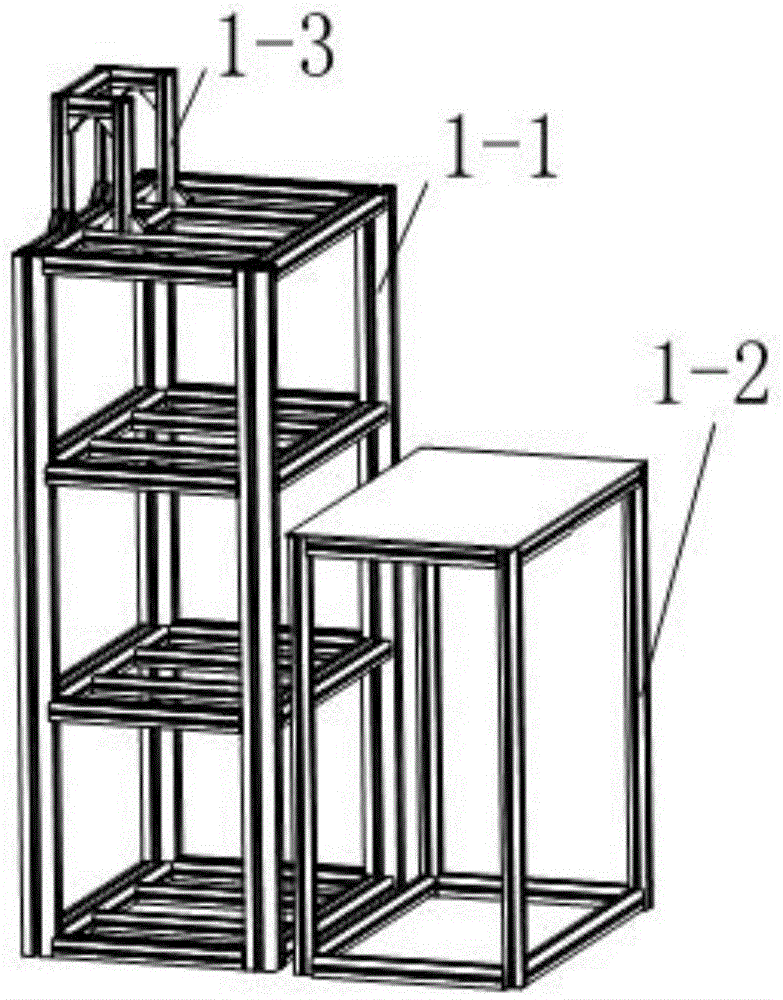

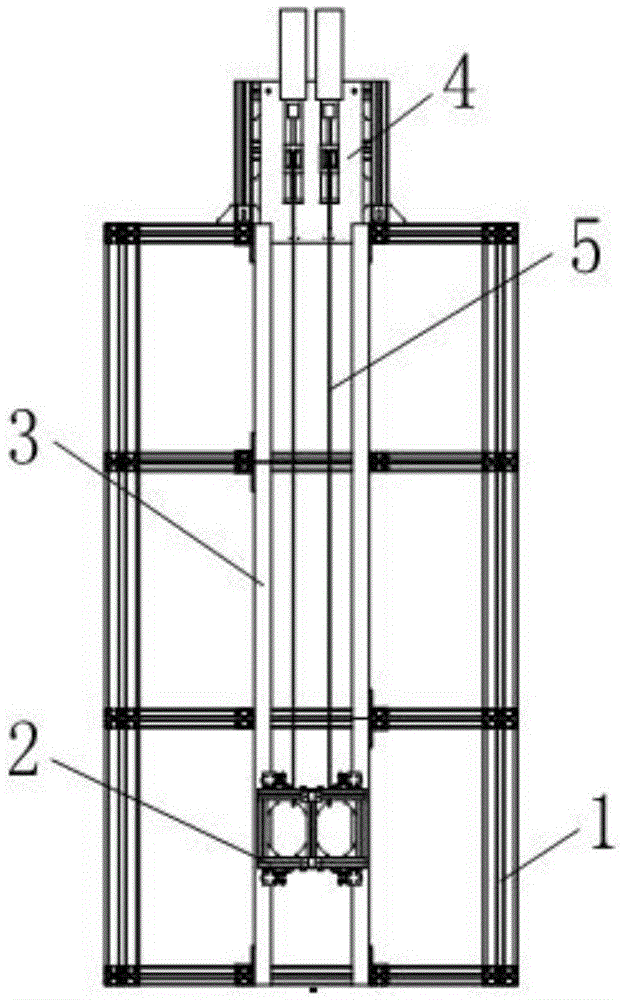

[0038] Such as figure 1 and2 As shown, a multi-functional simulation test platform for an ultra-deep mine hoisting system of the present invention includes a frame 1, a hoisting container 2, a rectangular guide rail 3, a rope adjustment device 4, a hoisting rope 5, a driving device 6, a detection control system 7, Tension rope 8 and tension device 9. The frame 1 includes a main frame 1-1, a sub-frame 1-2 is arranged on the side of the main frame 1-1, a top-level frame 1-3 is arranged on the top of the main frame 1-1, and the driving device 6 is installed on the sub-frame 1-1. 2, the rope adjustment device 4 is arranged on the top frame 1-3, one end of the hoisting rope 5 is wound on the reel 38 of the driving device 6, and the other end of the hoisting rope 5 is passed around the guide wheel 30 of the rope adjustment device 4 and connected to the Lift container 2 on;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com