Electrospinning device for preparing fluffy nanometer fibers

A nanofiber and electrospinning technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of tight fiber arrangement, fast fiber drop, and difficulty in obtaining fluffy fibers, etc., and achieves high degree of transplantability, Universal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the technical means adopted by the present invention, the device for collecting fluffy nanofibers proposed in the present invention and the process of the method are described in detail below in conjunction with preferred embodiments.

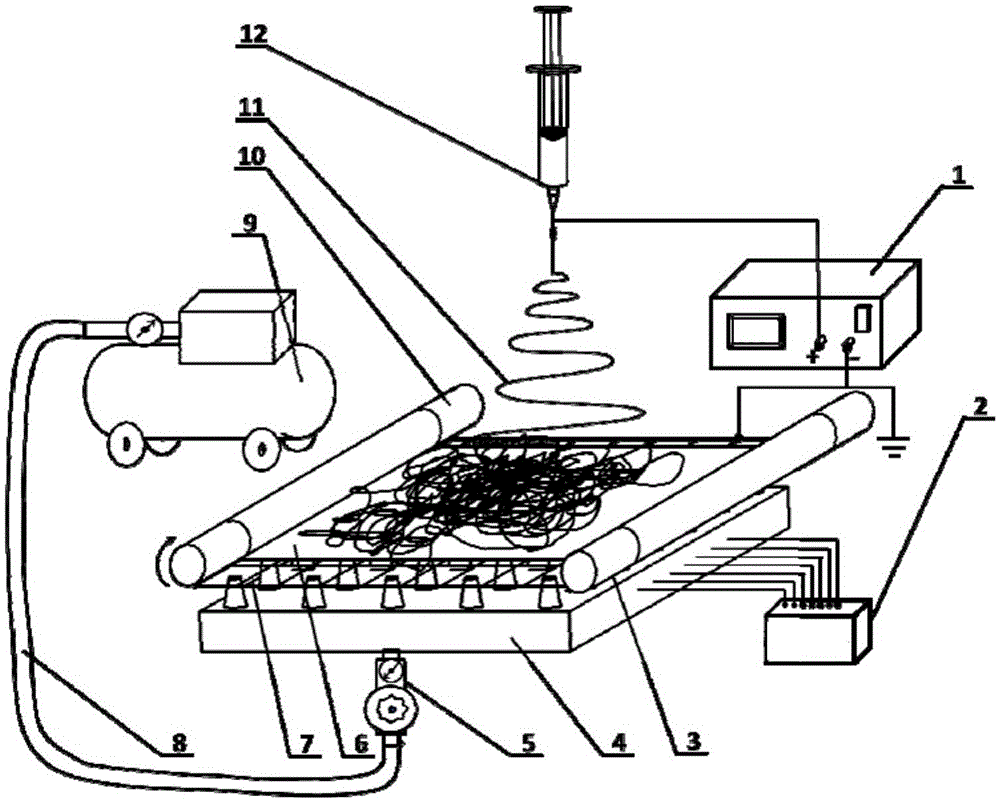

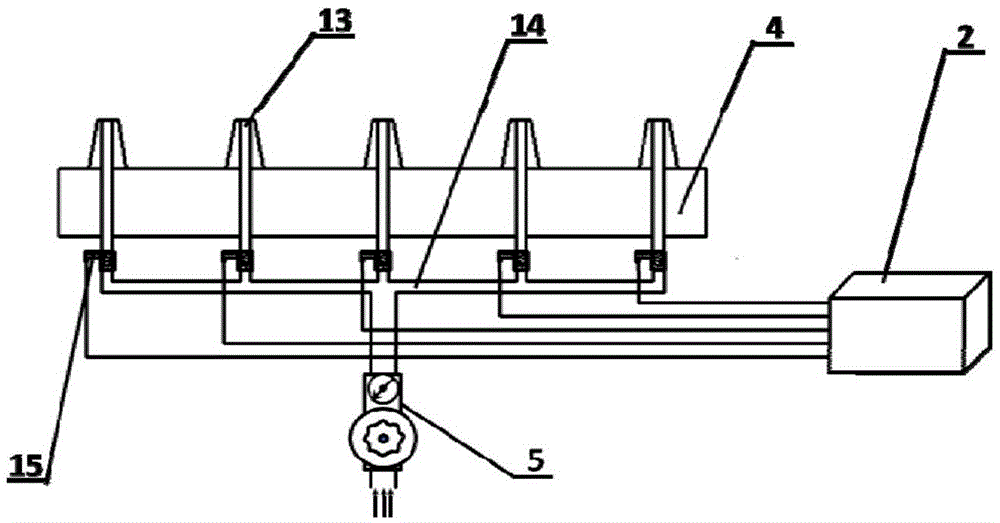

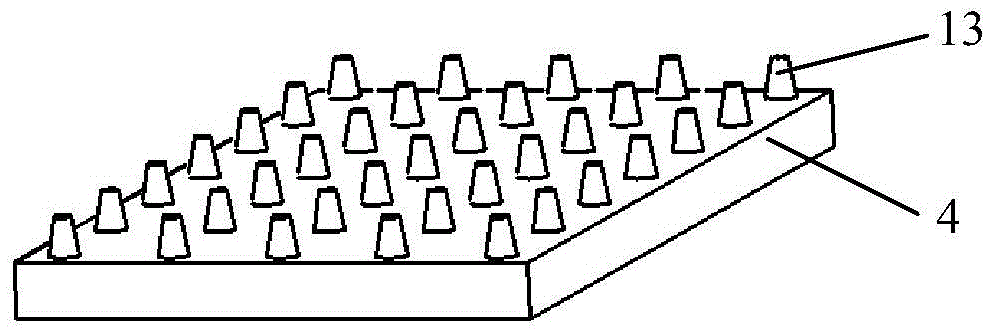

[0018] see Figure 1~4 , The embodiment of the present invention is provided with an electrospinning generating device, a collecting device, an air jet device, a controller 2, a high-pressure air pump 9, and an air pressure valve 5.

[0019] The electrospinning generating device is provided with a high-voltage power supply 1 and a spinning nozzle 12, the positive pole of the high-voltage power supply 1 is connected to the positive pole of the spinning nozzle 12, and the negative pole is grounded. The collection device is located directly below the spinning nozzle 12, and is provided with a winding shaft 10, an unwinding shaft 3, a PET melt-blown non-woven fabric 6 and a metal mesh 7, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com