Manufacturing and assembling method for variable-rigidity traction rubber pile and rigidity varying method

An assembly method and variable stiffness technology, which is applied in the field of rolling stock vibration reduction, can solve problems such as increased stiffness and low stiffness, and achieve the effects of reducing wear, reducing maintenance costs, and making assembly simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

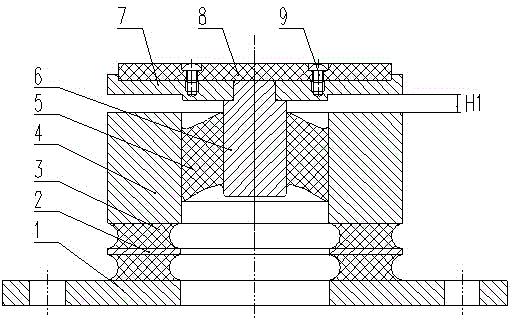

[0053] Such as figure 2 As shown, a variable stiffness traction rubber pile production and assembly method uses a special mold to vulcanize and bond the metal bottom plate 1 and the metal partition 2 through the bottom elastic rubber body 3, and the metal partition 2 and the metal jacket 4 pass through the bottom elastic The rubber body 3 is bonded together, the metal outer casing 4 and the metal inner casing 6 are vulcanized and bonded together through the upper elastic rubber body 5, the wear-resistant plate 8 and the metal top plate 7 are connected together by fastening screws 9, and the metal top plate 7 is passed through Ying fit is connected together with metal inner sleeve 6 tops. When the rubber stopper is loaded, the elastic rubber body 5 is deformed, the interval H1 of the gap section is gradually reduced to 0, and the metal top plate 7 is in contact with the metal jacket 4 to realize a sudden change in stiffness. The inflection point required by the variable stiff...

Embodiment 2

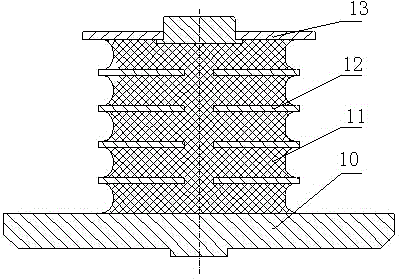

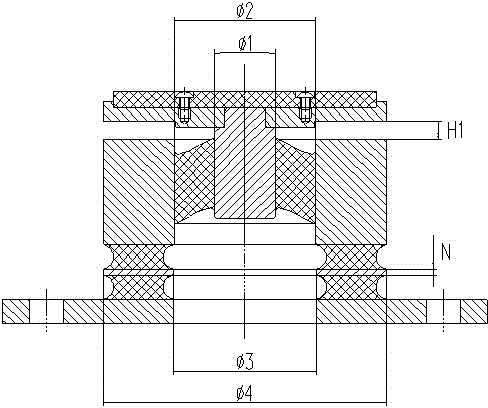

[0058] Such as image 3 As shown, on the basis of Example 1, in order to increase the stiffness of the first segment (stiffness under small displacement), the inner diameter of the metal jacket Φ2 is reduced, the outer diameter of the metal inner jacket is increased Φ1, and the inner surface of the metal jacket and the metal inner surface are reduced. The distance between the outer surfaces of the sleeve. In order to advance the inflection point of variable stiffness, the distance H1 between the metal bottom plate 7 and the metal jacket 4 is reduced. In order to increase the large displacement stiffness, the number of layers N of the metal separator 2 can be increased, and at the same time, the outer diameter Φ4 of the metal separator 2 (the metal separator is cylindrical) can be increased, and the inner diameter of the opening Φ3 can be reduced. By adjusting the parameters Φ1, Φ2, Φ3, Φ4, H1, and N, the combination of various stiffnesses and multi-position inflection points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com