Adsorbent prepared by utilizing molecular sieve contained waste catalyst, and removal method for methanol by using adsorbent

A waste catalyst, waste catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult disposal of waste catalysts, solid waste discharge polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

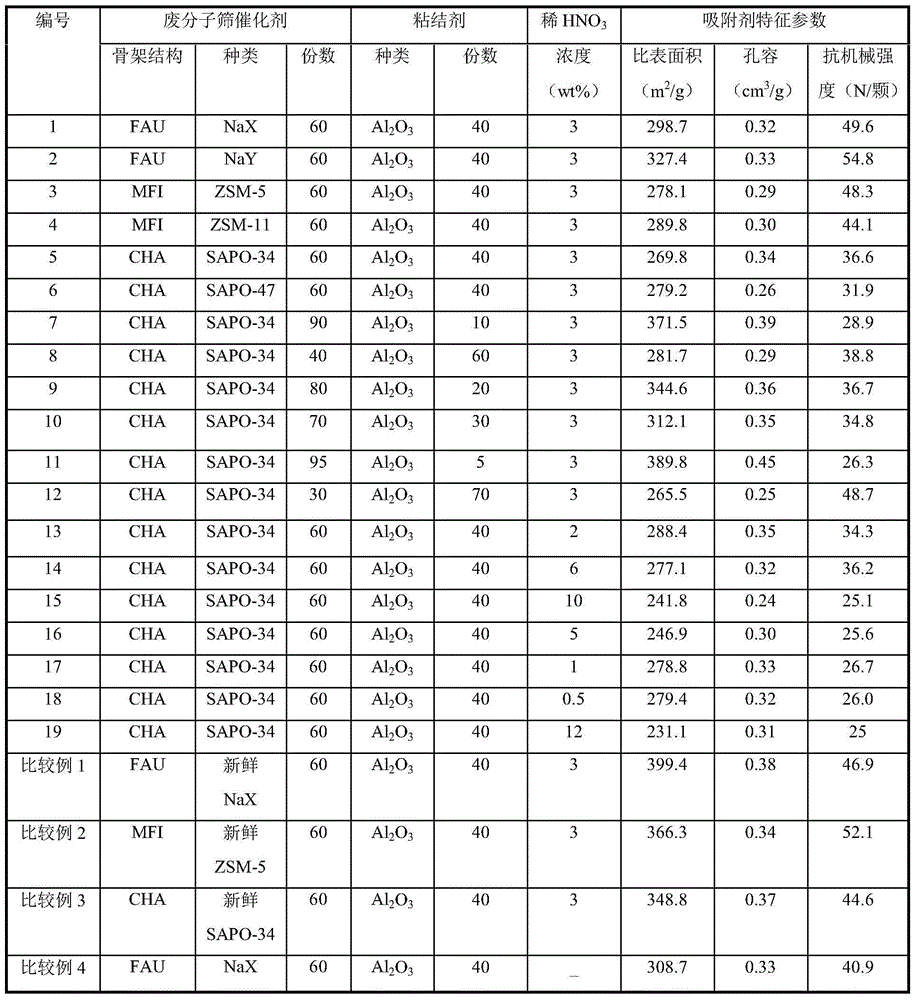

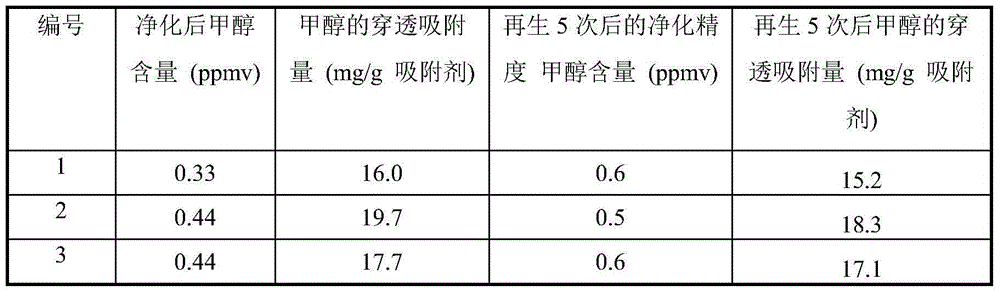

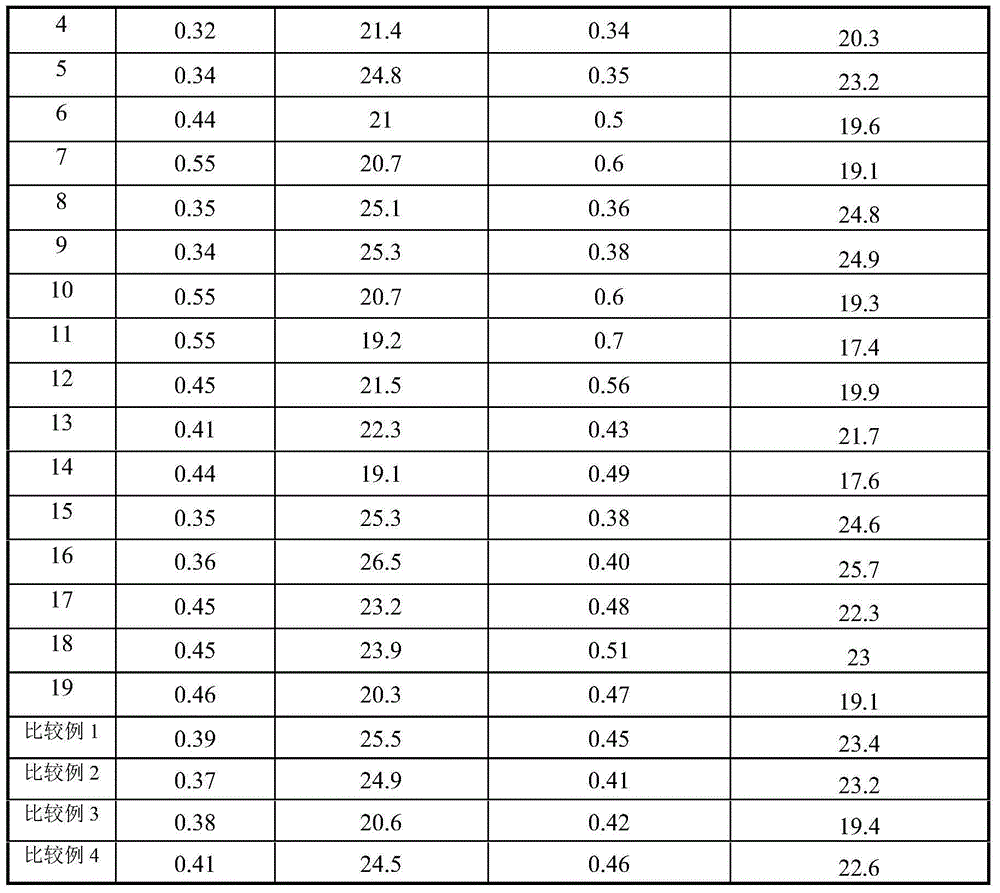

Embodiment 1

[0022] The preparation process of the adsorbent containing the spent catalyst containing NaX molecular sieve whose framework structure is FAU is as follows. First, 30ml of dilute nitric acid solution with a mass concentration of 3% was prepared for use in the process of forming the adsorbent. Weigh 30 g of spent catalyst whose main component is NaX molecular sieve. The specific surface area of the waste catalyst containing NaX molecular sieve is 336.4m 2 / g, the pore volume is 0.27cm 3 / g, the surface acid density of the spent catalyst is 163.0 μmol / g; based on the total weight of the spent catalyst containing molecular sieves, in parts by weight, Al 2 o 3 The content is 30 parts, SiO 2 The content is 48 parts, P 2 o 5 The content is 0 parts, Na 2 O, K 2 The total content of O, MgO and CaO is 8 parts, and the amount of carbon deposition is 5 parts. Then, weigh 20gAl 2 o 3 , and the above-mentioned waste catalyst containing molecular sieve and binder Al 2 o 3 Mix...

Embodiment 2

[0025] The preparation process of the adsorbent containing the spent NaY molecular sieve catalyst with the framework structure of FAU is as follows. First, 30ml of dilute nitric acid solution with a mass concentration of 3% was prepared for use in the process of forming the adsorbent. The specific surface area of the waste catalyst containing NaY molecular sieve is 356.2m 2 / g, the pore volume is 0.29cm 3 / g, the surface acid density of the spent catalyst is 173.0μmol / g; based on the total weight of the spent catalyst containing molecular sieves, in parts by weight, Al 2 o 3 The content is 20 parts, SiO 2 The content is 48 parts, P 2 o 5 The content is 0 parts, Na 2 O, K 2 The total content of O, MgO and CaO is 9 parts, and the amount of carbon deposition is 4 parts. Take by weighing 30g the waste catalyst that main component is NaY molecular sieve, then weigh 20gAl 2 o 3 , and the above-mentioned waste catalyst containing molecular sieve and binder Al 2 o 3 Mixe...

Embodiment 3

[0028] The preparation process of the adsorbent containing the spent catalyst containing ZSM-5 molecular sieve whose skeleton structure is MFI is as follows. First, 30ml of dilute nitric acid solution with a mass concentration of 3% was prepared for use in the process of forming the adsorbent. The specific surface area of the spent catalyst containing ZSM-5 molecular sieve is 214.7m 2 / g, the pore volume is 0.25cm 3 / g, the surface acid density of the spent catalyst is 158.0 μmol / g; based on the total weight of the spent catalyst containing molecular sieves, in parts by weight, Al 2 o 3 The content is 10 parts, SiO 2 The content is 48 parts, P 2 o 5 The content is 0 parts, Na 2 O, K 2 The total content of O, MgO and CaO is 9 parts, and the amount of carbon deposition is 12 parts. Take by weighing 30g main component to be the spent catalyst of ZSM-5 molecular sieve, then weigh 20gAl 2 o 3 , and the above-mentioned waste catalyst containing molecular sieve and binder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com