A slow-release anti-mold molecular sieve, anti-mold desiccant and preparation method thereof

A molecular sieve and slow-release technology, applied in separation methods, botanical equipment and methods, chemical instruments and methods, etc., can solve the problems of no anti-mold effect and poor anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An anti-mildew desiccant, calculated in parts by weight, comprises the following components: 100 parts of bentonite, 80 parts of sepiolite, 40 parts of cross-linked sodium polyacrylate, and 50 parts of slow-release anti-mildew molecular sieve.

[0019] Among them, the slow-release anti-mildew molecular sieve, calculated in parts by weight, includes the following components: fumigant and mustard oil, PEG 4000, water-based resin E100, plasticizer and molecular sieve with a particle size of 1 mm.

[0020] The preparation method of the slow-release anti-mildew molecular sieve is as follows:

[0021] Add 200 parts of molecular sieves with a particle size of 1mm in the coating pan, keep the temperature at room temperature, and adjust the rotation speed to 60r / min; then add 25 parts of fumigant, keep the rotation speed constant, for 10 minutes, to ensure that the molecular sieve can fully absorb the fumigant; add mustard 35 parts of oil, keep the speed constant, time 10min, to...

Embodiment 2

[0025] An anti-mildew desiccant, calculated in parts by weight, comprises the following components: 180 parts of bentonite, 140 parts of sepiolite, 30 parts of cross-linked sodium polyacrylate, and 90 parts of slow-release anti-mildew molecular sieve.

[0026] Among them, the slow-release anti-mildew molecular sieve, calculated in parts by weight, includes the following components: fumigant and mustard oil, PEG 2000, water-based resin S100, plasticizer and molecular sieve with a particle size of 2 mm.

[0027] The preparation method of the slow-release anti-mildew molecular sieve is as follows:

[0028] Add 110 parts of molecular sieves with a particle size of 1mm in the coating pan, keep the temperature at room temperature, and adjust the speed at 60r / min; add 20 parts of fumigant, keep the speed constant, and keep the speed constant for 10 minutes to ensure that the molecular sieve can fully absorb the fumigant; add mustard oil 30 parts, keep the rotation speed constant, and...

Embodiment 3

[0032] Calculation of theoretical dosage of desiccant:

[0033] U=30.4×C×A×R×M×DRF / B

[0034] U: number of desiccant units

[0035] A desiccant unit is defined as: at 25°C equilibrium temperature, according to the adsorption capacity of the desiccant, the weight of the desiccant required to absorb the following weights of water vapor in different humidity environments.

[0036] 3.00g at 20% relative humidity,

[0037] 6.00g at 40% relative humidity.

[0038] A: The inner surface area of the moisture barrier packaging bag (excluding the sealing area) (in 2 )

[0039] R: Water vapor transmission rate of the moisture barrier packaging bag ([g / 100in 2 ] / 24h)

[0040] M: maximum storage time (month)

[0041] DRF: desiccant reduction factor (see Table 1 below)

[0042] B: The minimum moisture absorption capacity of the desiccant at MIH (maximum humidity in the package) (g / unit)

[0043] C: 0.01 area constant (100in 2 / in 2 )

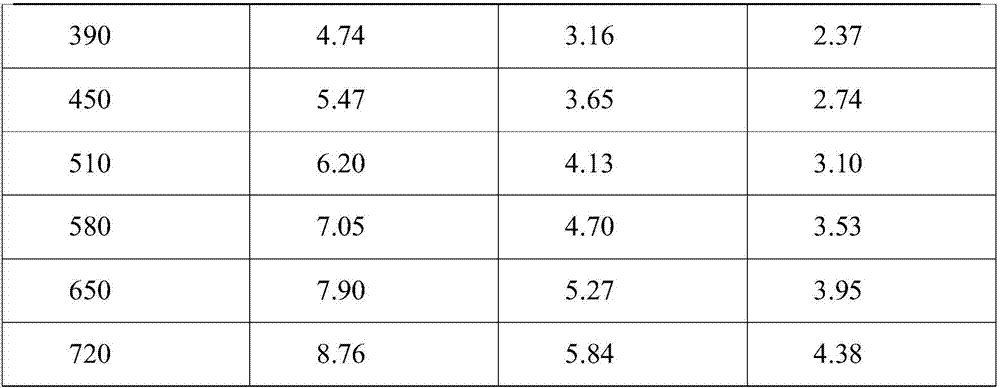

[0044] Table 1 Desiccant reduction factor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com