A motor controller

A motor controller and controller technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems that do not conform to the development trend of low cost and small size of motor vehicles, affect the operating efficiency of motor controllers, occupy the space of motor vehicles, etc. , to achieve ideal cooling effect, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

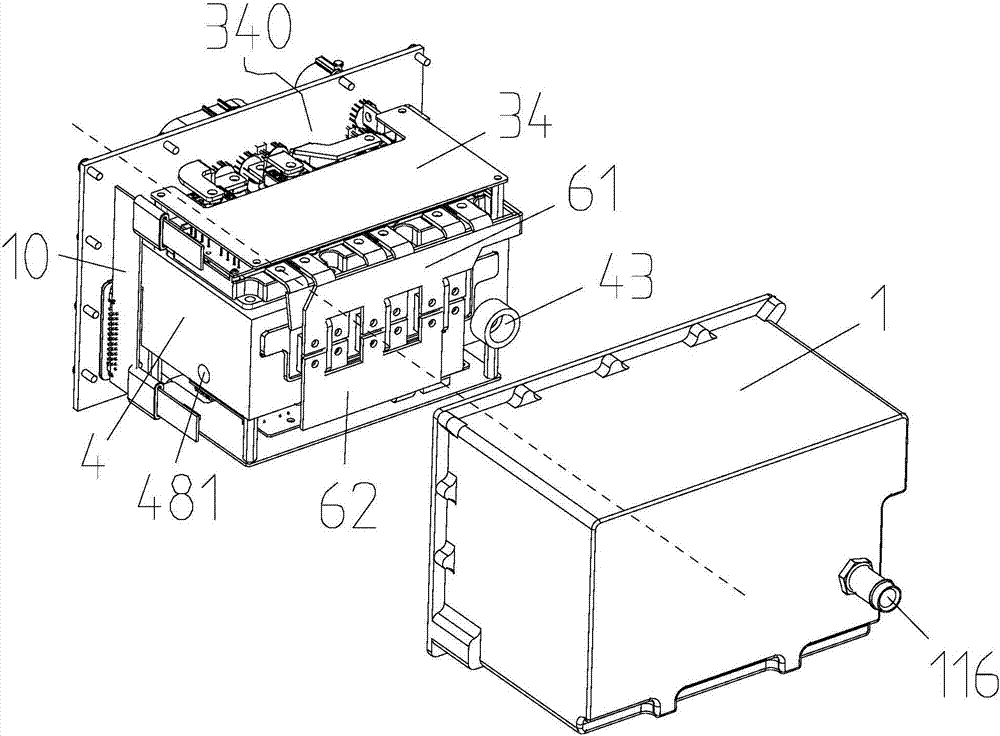

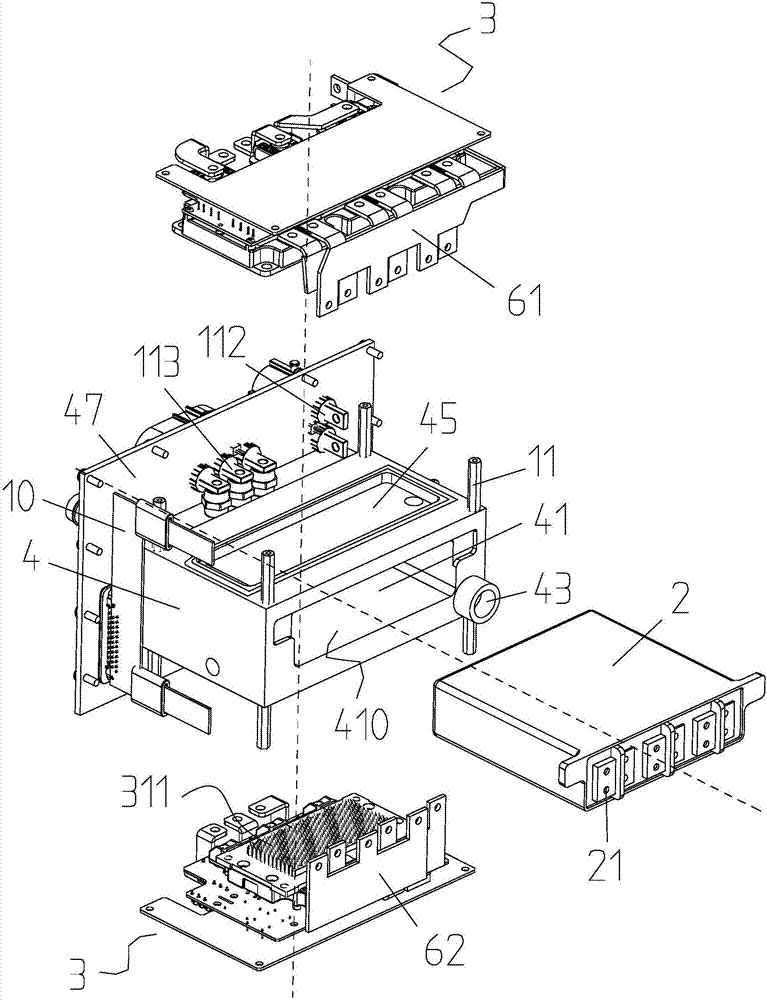

[0035] Embodiment one: if Figure 1 to Figure 9 As shown, the present invention is a motor controller, including a controller box 1, a capacitor module 2 and two inverter modules 3, a radiator 4 is installed inside the controller box 1, and a radiator 4 is provided in the middle of the radiator 4 The cavity 41, the capacitor module 2 is installed inside the cavity 41, the two inverter modules 3 are installed on the top and the bottom of the radiator 4 respectively, and a cooling water channel 42 is opened on the radiator 4 and is provided with a cooling channel 42 communicating with the cooling channel 42. The water inlet 43 and the water outlet 44 of the cooling water channel 42 dissipate heat to the capacitor module 2 and the two inverter modules 3 . The inverter module 3 includes an IGBT module 32 , a drive circuit board 33 and a control circuit board 34 , and the drive circuit board 33 and the control circuit board 34 are installed on the top surface of the IGBT module 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com