A method for improving the efficiency of light strips and gongs

A technology of lamp strips and gong boards, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of inability to make boards, low efficiency of gong boards, and inability to guarantee quality, so as to simplify operations and improve the quality of gong boards. Quality, improve the effect of gong board efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

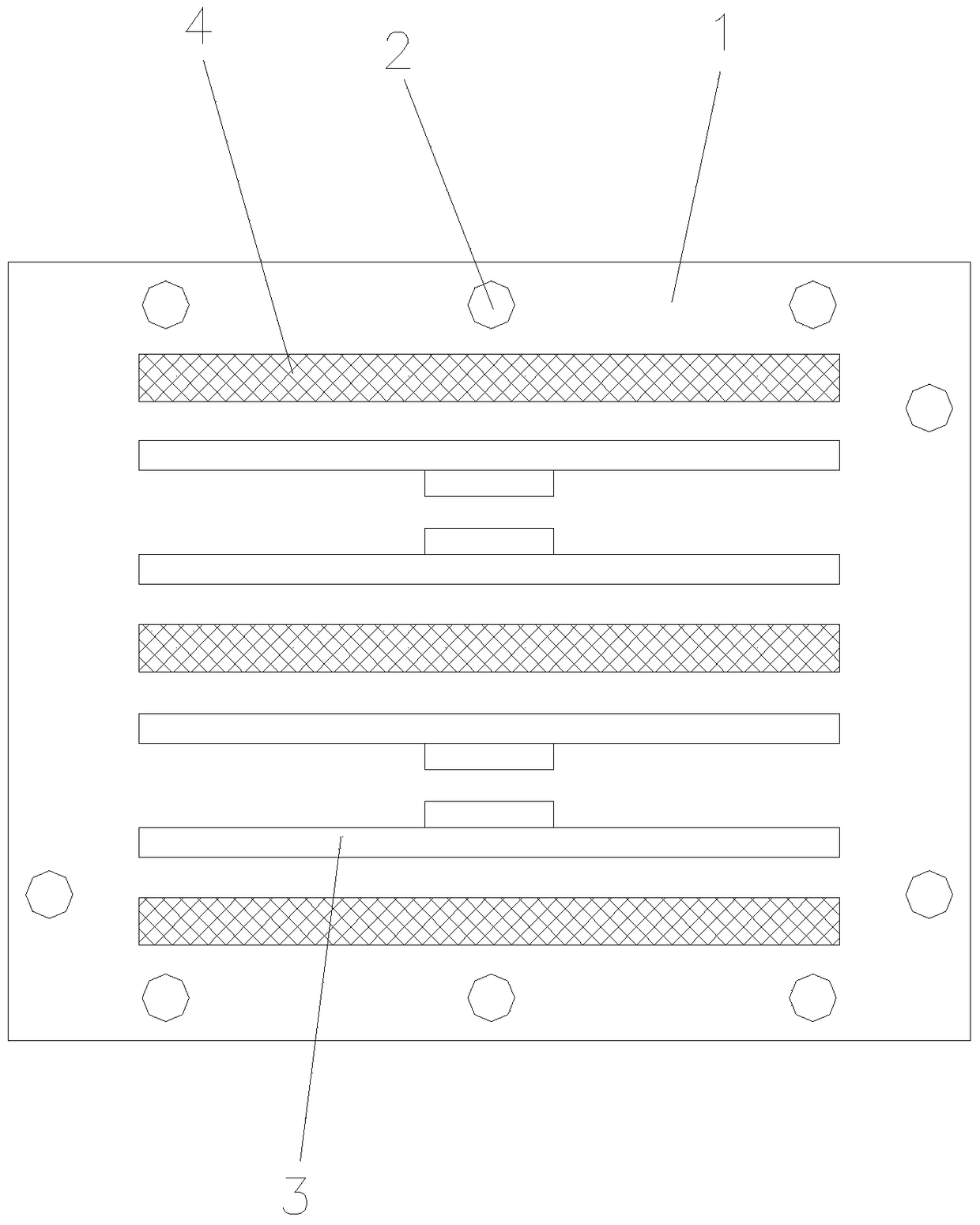

[0015] Such as figure 1 As shown, a method to improve the efficiency of the light strip panel, including:

[0016] 1) Use the first gong machine with a positioning pin and a pressing mechanism to gong board the long sides of the stacked light strips. The first gong machine is an ordinary gong machine in the prior art. In the process of gong boarding, the horizontal positioning of each light strip is completed by extending the positioning pin of the first gong machine into the preset positioning hole on each light strip, and the vertical positioning of each light strip is through the first gong It is completed by pressing the pressing mechanism of the machine on the surface of the uppermost layer of light strips;

[0017] 2) Make a positioning plate with positioning pin holes and positioning grooves and sticky tape on the surface, put on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com