Battery system

A battery system and battery technology, applied in the direction of secondary batteries, battery overcharge protection, battery disconnection circuit, etc., can solve the problem of increasing the battery voltage above the upper limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

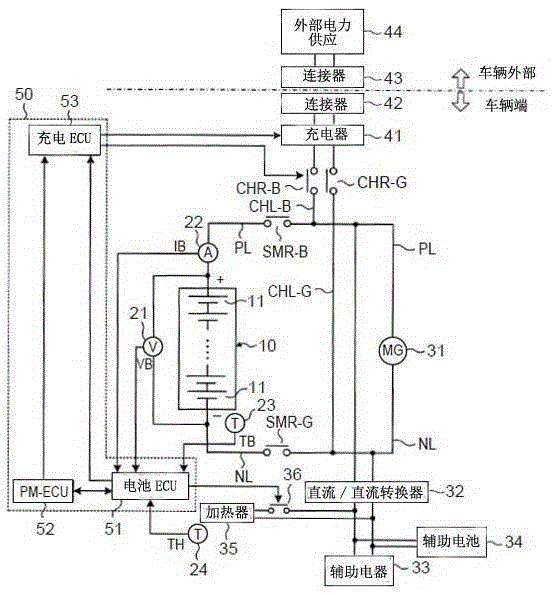

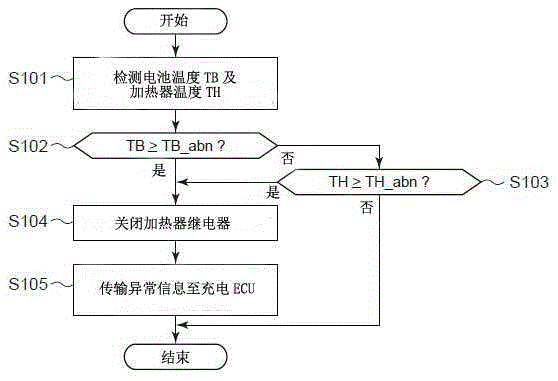

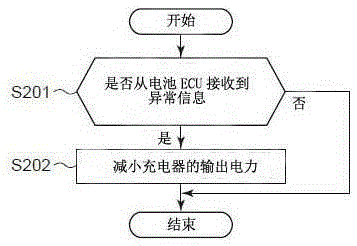

[0030] figure 1 It is a schematic structural diagram of the battery system of this embodiment. figure 1 The battery system shown is installed on a vehicle.

[0031] The main battery 10 has a plurality of unit cells 11 connected in series. As the unit battery 11 , for example, a secondary battery such as a nickel hydrogen battery or a lithium ion battery can be used. The main battery 10 may include a plurality of unit cells 11 connected in parallel.

[0032] figure 1 The illustrated battery system is controlled by an ECU (Electronic Control Unit) 50 . The ECU 50 described here is configured to include a battery ECU 51 , a power management ECU (PM-ECU) 52 , and a charging ECU 53 . The ECU 50 corresponds to the controller of the present invention.

[0033] Voltage sensor 21 detects voltage value VB of main battery 10 and outputs the detection result to battery ECU 51 . The current sensor 22 detects the current value IB of the main battery 10 and outputs the detection resul...

Embodiment 2

[0096] Embodiment 2 of the present invention will be described below. In this embodiment, differences from Embodiment 1 are mainly described.

[0097] In Embodiment 1, in the case where power is supplied to the heater 35 after the SOC of the main battery 10 reaches the threshold SOC_th, power is not supplied to the main battery 10 . On the other hand, in the present embodiment, after the SOC of the main battery 10 reaches the threshold SOC_th, electric power is supplied to the heater 35 , and by supplying electric power to the main battery 10 , also The constant current and constant voltage charging.

[0098] The external charging process in this embodiment will combine Figure 8 The flow chart shown is described. Figure 8 equivalent to Figure 4 , and with Figure 4 Processes that are the same as those described are denoted by the same reference numerals. exist Figure 8 In the flow shown, with Figure 4 Where the flow shown differs will be mainly described below.

...

Embodiment 3

[0109] Embodiment 3 of the present invention will be described below. In this embodiment, differences from Embodiment 2 are mainly described.

[0110] In Embodiment 2, constant current charging is performed with electric power α until the SOC of the main battery 10 reaches the threshold SOC_th. In this embodiment, the charging power during constant current charging is weakened before the SOC of the main battery 10 reaches the threshold SOC_th. Then, after the SOC of the main battery 10 reaches the threshold SOC_th, similar to Embodiment 2, constant current and constant voltage charging is performed by supplying power to the main battery 10 regardless of whether power is supplied to the heater device 35.

[0111] The flow of external charging in this embodiment will be set Figure 10 and Figure 11 The flow chart in is described. Figure 10 and Figure 11 equivalent to Figure 8 .

[0112] In step S401 , the battery ECU 51 calculates the SOC of the main battery 10 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com