A self-balancing pay-off block and traction plate for tension stringing

A technology of pay-off block and tension stringing, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of many suspension blocks, unfavorable operation of tight lines and accessories, and large traction force, so as to increase the selectivity of construction technology and strengthen the promotion value , to avoid the effect of job hopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

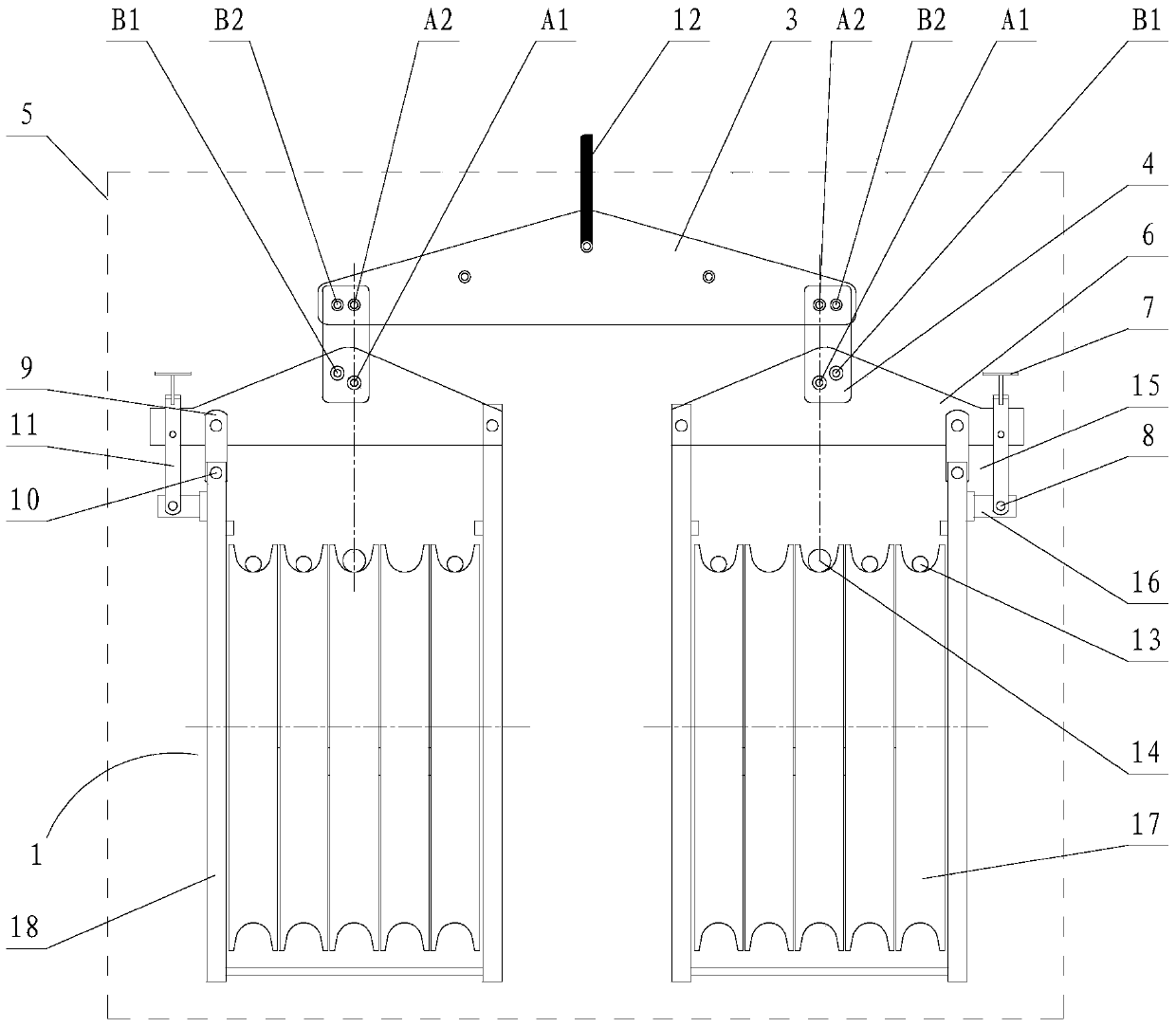

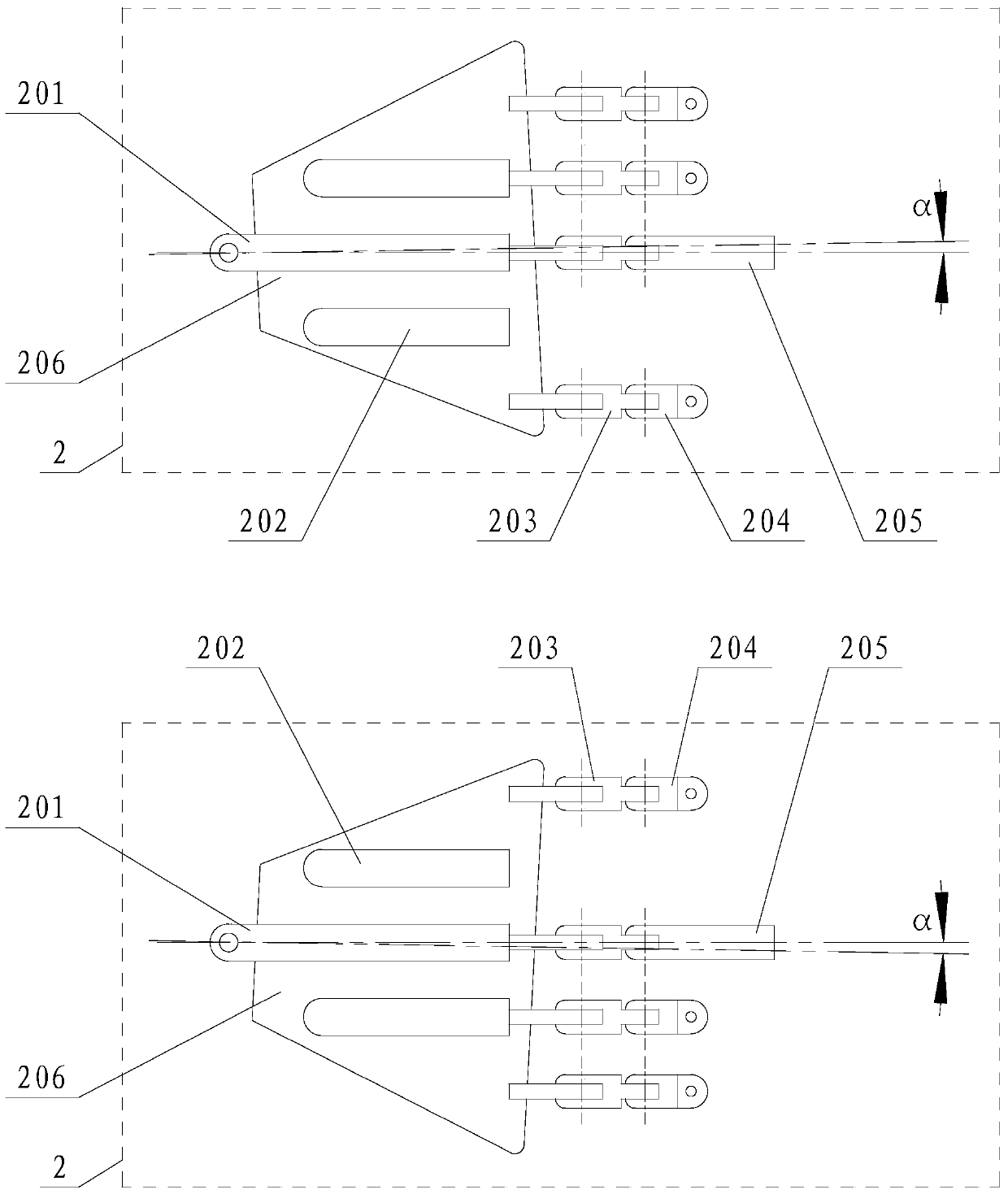

[0020] Such as figure 1 , figure 2 The present invention shown includes tension stringing block 5 and eccentric running board 2, wherein tension stringing block 5 includes two connecting boards 3, parallel hanging boards 4 and odd number wire pay-off block 1, and eccentric running board 2 includes guide rods 202 , guide rod joint 203 , wire connector 204 , anti-twist counterweight 205 and walking board body 206 .

[0021] The double plate 3 is an isosceles triangle, and its top is provided with three suspension holes that are distributed in an isosceles triangle, and two ends of the bottom are respectively provided with two suspension holes, and the two suspension holes at the two ends on the inside are A2, and the two ends are located at The two hanging holes on the outside are B2, and the four hanging holes (two A2 and two B2) at both ends of the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com