Longitudinal cooler system for laser crystal

A technology for coolers and lasers, which is applied in the direction of laser cooling devices, lasers, laser components, etc., can solve the problems of large temperature difference of coolers, unreasonable design of coolers, and uneven temperature distribution, so as to ensure normal operation and maintain uniformity, reducing the effect of thermal gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

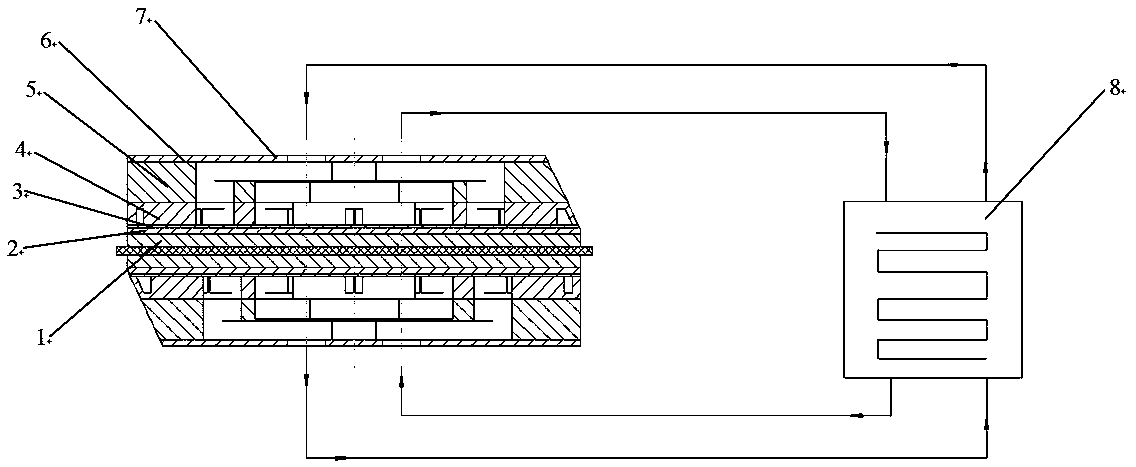

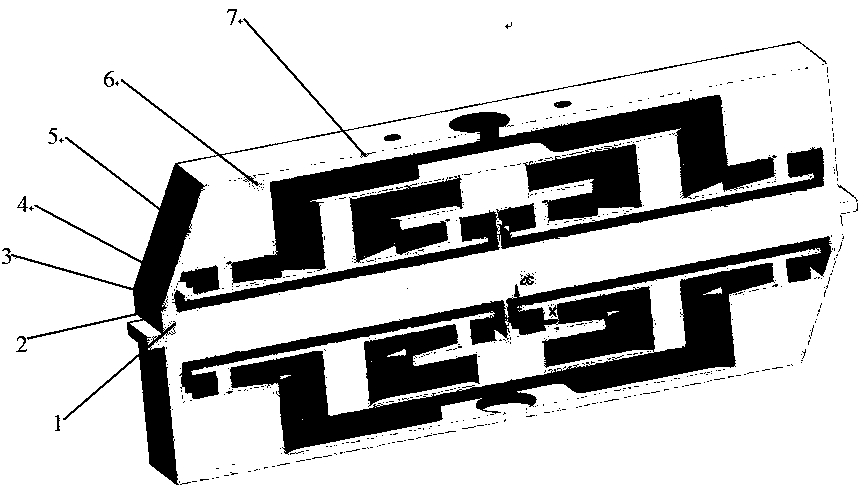

[0028] Such as Figure 1-Figure 2 As shown, the longitudinal cooler system for laser crystals of the present invention includes an upper cover plate layer 1, a heat dissipation layer 2, a small hole water separation plate layer 3, a width water separation plate layer 4, a cooling water merging layer 5, an auxiliary Welding sheet layer 6, bottom cover layer 7, temperature control cooling equipment;

[0029] The upper cover plate layer 1, the heat dissipation layer 2, the small hole water separation plate layer 3, the width water separation plate layer 4, the cooling water merging layer 5, the auxiliary solder plate layer 6 and the bottom cover plate layer 7 are stacked in sequence from bottom to top The upper and lower layers are fastened and sealed by welding; the auxiliary solder sheet layer 6 and the bottom cover layer 7 have a common water inlet and a total water outlet, and the total water inlet and temperature control of the bottom cover layer 7 The water outlet of the r...

Embodiment 2

[0043] Embodiment 2 is basically the same in structure and implementation as Embodiment 1, the main difference being:

[0044] The upper cover layer 1, the heat dissipation layer 2, the small hole water separation layer 3, the width water separation layer 4, the cooling water merging layer 5, the auxiliary solder sheet layer 6 and the bottom cover layer 7 adopt a thermal conductivity of 350W / (m·K) made of metal material, the contact surface of each layer is a mirror surface with a flatness equal to 20μm before welding.

[0045] The lower surface of the upper cover layer 1 is a mirror surface with a flatness equal to 8 μm.

[0046] The width of the water inlet hole and the water outlet hole of the small hole water separation plate layer 3 is equal to 400um, the width of the heat dissipation channel of the heat dissipation layer 2 is equal to 400um, the length of the small hole is equal to 1.2mm, and the length and width ratio of a single heat dissipation channel It is equal t...

Embodiment 3

[0051] Embodiment 3 is basically the same in structure and implementation as Embodiment 1, the main difference is:

[0052] The upper cover plate layer 1, the heat dissipation layer 2, the small hole water separation plate layer 3, the width water separation plate layer 4, the cooling water merging layer 5, the auxiliary solder plate layer 6 and the bottom cover plate layer 7 adopt a thermal conductivity of 400W / (m·K) made of metal material, the contact surface of each layer is a mirror surface with a flatness equal to 10μm before welding.

[0053] The lower surface of the upper cover layer 1 is a mirror surface with a flatness equal to 6 μm.

[0054] The width of the water inlet hole and the water outlet hole of the small hole water separation plate layer 3 is equal to 300um, the length of the hole is equal to 0.9mm, the width of the heat dissipation channel of the heat dissipation layer 2 is equal to 300um, and the length and width ratio of a single heat dissipation channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com