Frequency selection surface structure based on stereo structure

A frequency selective surface, three-dimensional structure technology, applied in electrical components, antennas, etc., can solve problems such as few controllable parameters, small slope of frequency response curve, and poor miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

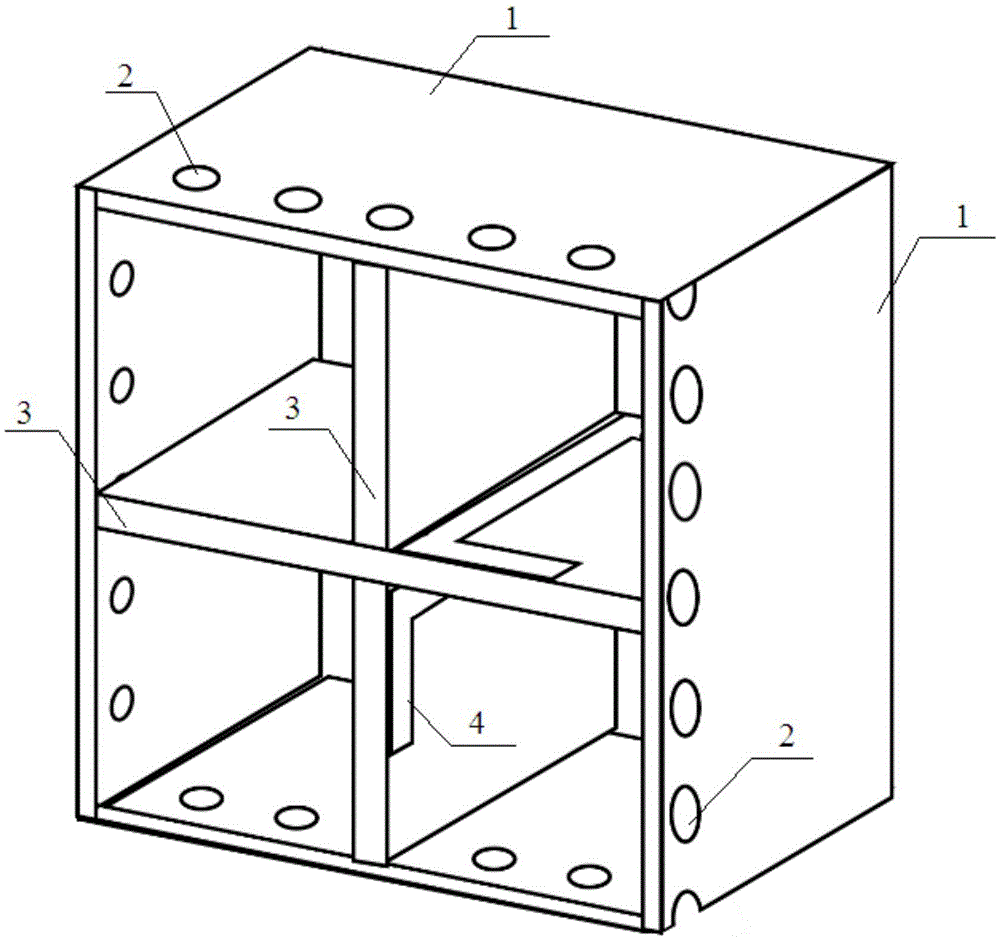

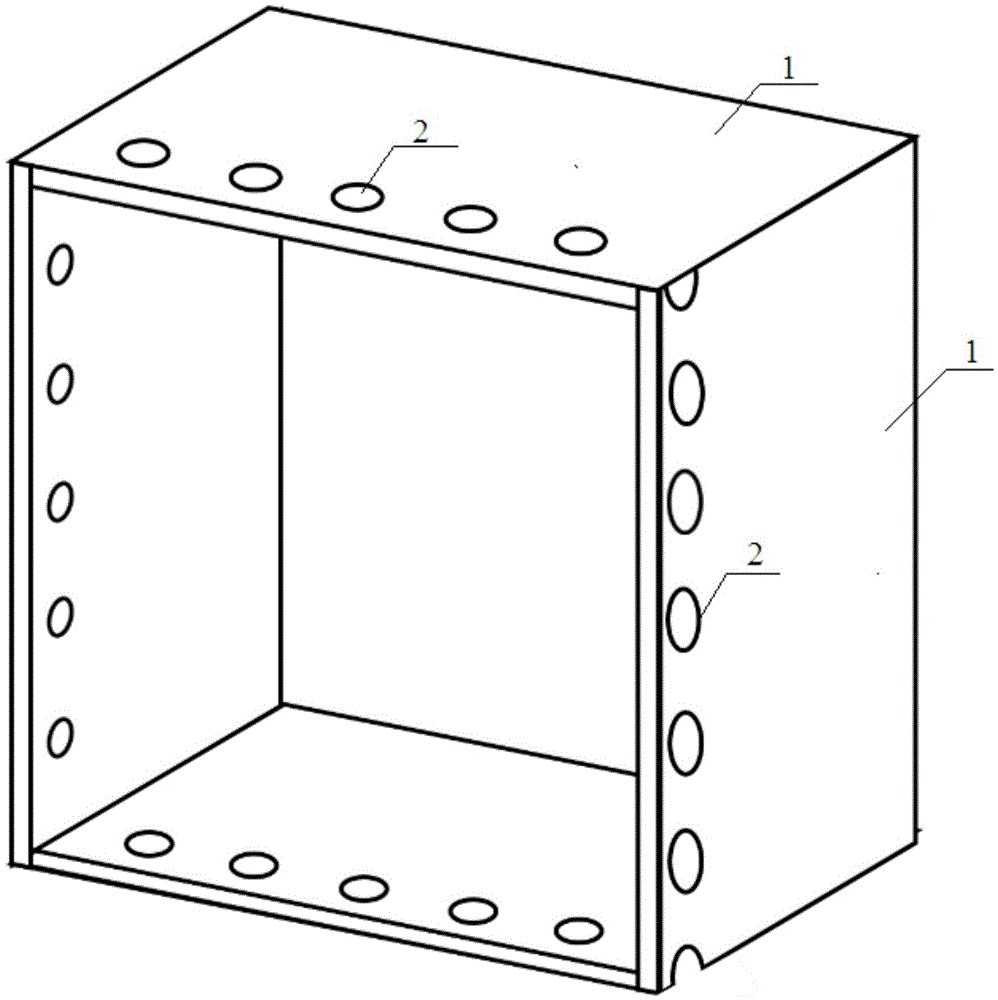

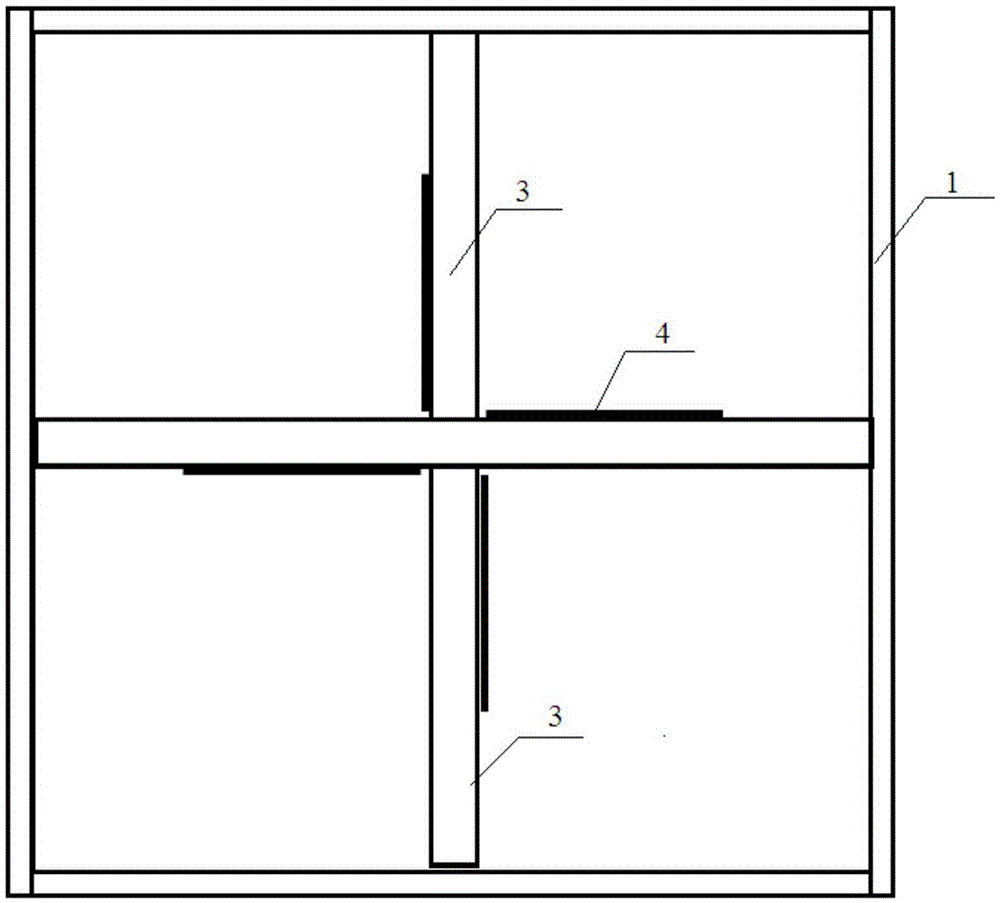

[0018] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, the frequency selective surface structure based on the three-dimensional structure described in this embodiment includes n frequency selective unit structures, and the n frequency selective unit structures are loaded in an array, and each frequency selective unit structure includes four No. 1 dielectric board 1, two No. 2 dielectric boards 3 and metal film strips 4; n is an integer greater than 1;

[0019] Four No. 1 dielectric boards 1 are vertically spliced to form a rectangular frame. The inner wall of the rectangular frame is coated with a metal film layer. The No. 1 dielectric board 1 is provided with circular through holes, and the circular through holes are arranged at equal intervals near the incident side of electromagnetic waves. , the circular through holes on the two dielectric plates 1 opposite to the rectangular frames are arranged oppositely, and the inner side o...

specific Embodiment approach 2

[0021] Embodiment 2. This embodiment is a further description of the frequency selective surface structure based on the three-dimensional structure described in Embodiment 1. The length of the rectangular frame formed by the vertical splicing of No. 1 dielectric plate 1 is 15.6 mm and the width is 15.6 mm. , The height is 10mm.

specific Embodiment approach 3

[0022] Embodiment 3. This embodiment is a further description of the three-dimensional structure-based frequency selective surface structure described in Embodiment 1. The dielectric constant of No. 1 dielectric plate 1 is 4.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com