Normally-off HEMT device with longitudinal grid structure and manufacturing method thereof

A gate structure, normally-off technology, which is applied in the field of normally-off HEMT devices and their preparation, can solve the problems of large threshold voltage, low device on-resistance and high switching rate, reduce device on-on resistance, etc., and achieve stability High threshold voltage and low on-resistance, reduced gate on-resistance, and good performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

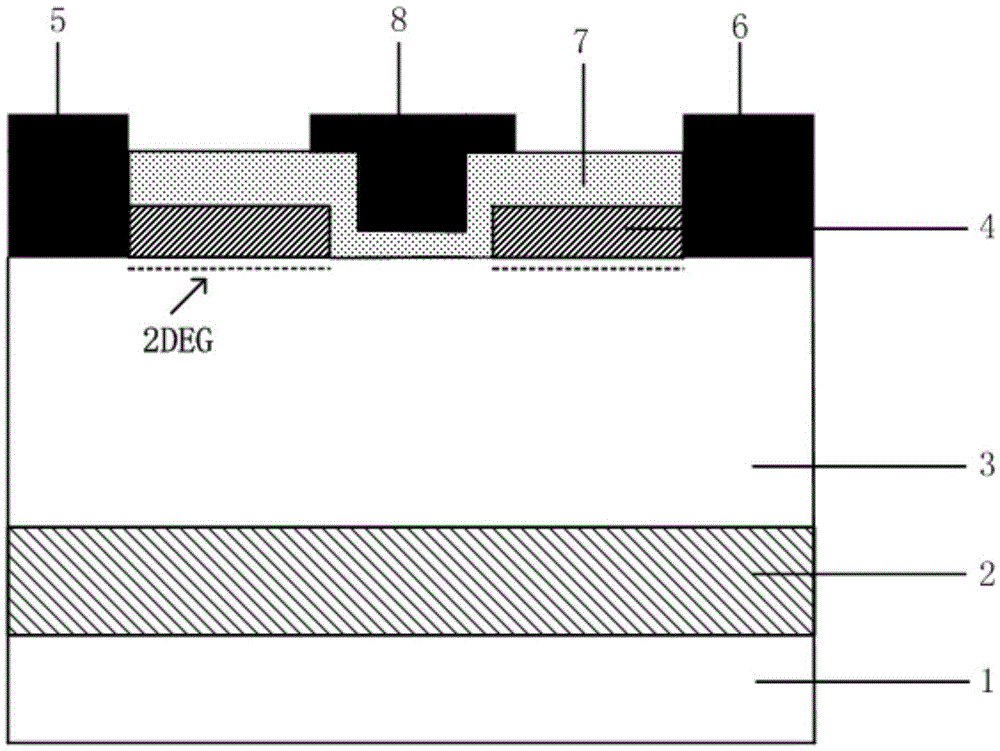

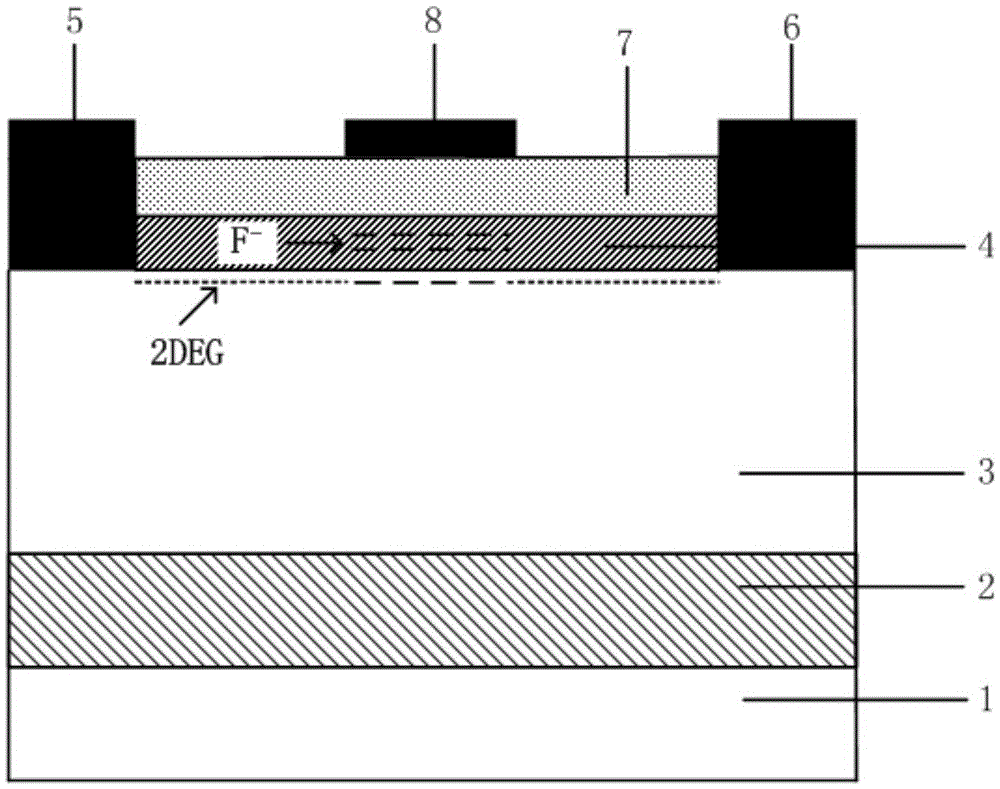

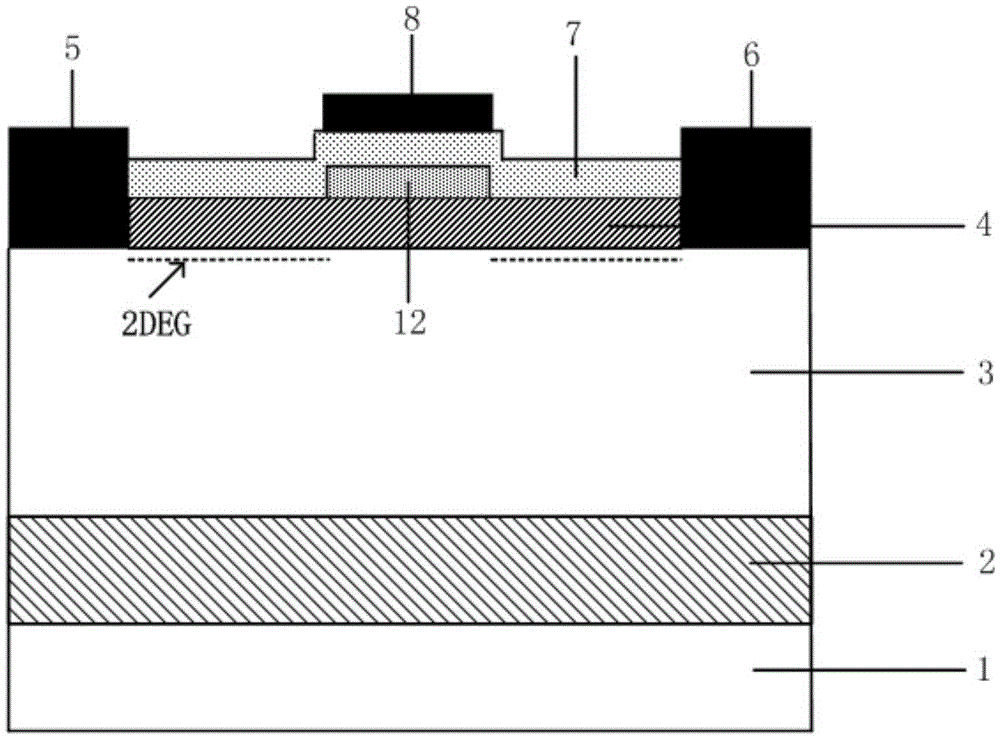

[0043] figure 2 It is a structural schematic diagram of a normally-off HEMT device with a vertical gate structure provided by an embodiment of the present invention. like figure 2 As shown, the normally-off HEMT device with a vertical gate structure provided by the embodiment of the present invention includes:

[0044] A substrate 1, a buffer layer 2, an i-GaN layer 3, a gate dielectric layer 7, and a passivation layer 9 are stacked, wherein one end of the i-GaN layer 3 and the side away from the buffer layer 2 are stepped;

[0045] The source electrode 5 covering between the ladder-shaped lower layer and the gate dielectric layer 7;

[0046] Covering the barrier layer 4 and the drain electrode 6 between the ladder-shaped upper layer and the gate dielectric layer 7, the drain electrode 6 is in contact with the barrier layer 4, wherein the drain electrode 6 is away from the ladder shape;

[0047] Cover the gate electrode 8 between the gate dielectric layer 7 and the passiv...

Embodiment 2

[0056] Figure 4 The implementation flow chart of the manufacturing method of the normally-off HEMT device with the vertical gate structure provided by the embodiment of the present invention. The method provided in this embodiment can manufacture a normally-off HEMT device with a vertical gate structure provided in any embodiment of the present invention. like Figure 4 As shown, the method for preparing a normally-off HEMT device with a vertical gate structure provided by an embodiment of the present invention includes:

[0057] Step 1, growing a buffer layer 2, an i-GaN layer 3 and a barrier layer 4 on a substrate 1 in sequence.

[0058] Figure 5a It is a structural diagram corresponding to this step of the method for fabricating a normally-off HEMT device with a vertical gate structure provided by an embodiment of the present invention. refer to Figure 5a , the specific process is: providing a substrate 1; forming a buffer layer 2 on the substrate 1; forming an i-Ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com