Lid for gas-tight seal and manufacturing method of the same, electronic component receiving package using the same

An air-tight sealing and manufacturing method technology, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of thinning electronic parts that are not easy to achieve, and achieve the effect of improving air-tight sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

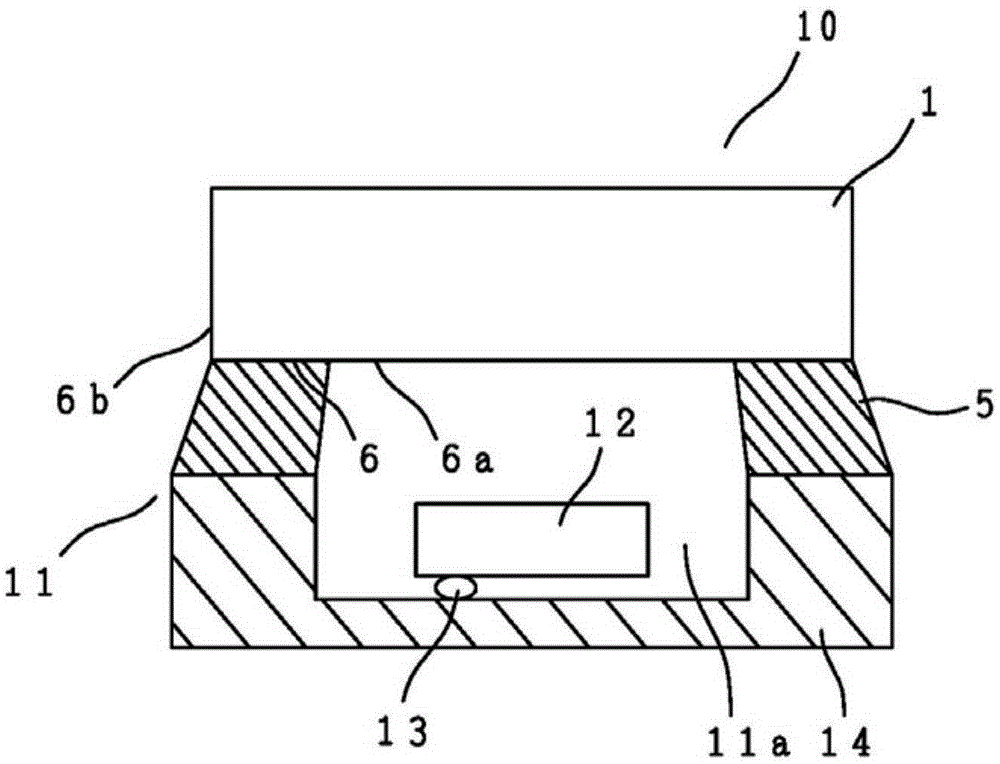

[0082] Examples of the present invention are disclosed below and described in detail. However, embodiments of the present invention are not limited to the examples of the present invention disclosed here.

[0083] In the cover 1 as an example of the present invention, the second metal layer 3 that contains more than 90% by mass of Ni and does not substantially contain Cr is clad and bonded to the first metal that is made of Fe-42Ni-6Cr alloy (426 alloy). Layer 2, and singulated by press processing. The thickness of the first metal layer 2 of the singulated lid 1 is 77 μm, and the thickness of the second metal layer 3 is 3 μm. The separated lid 1 was heat-treated for 30 minutes in a furnace set in a humid hydrogen atmosphere at a holding temperature of 850° C. and a dew point of +23.5° C. to form an oxide film layer 4 containing Cr to produce the lid 1 .

[0084] About the produced cover 1, the appearance photograph of the surface of the first metal layer 2 is shown in Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com