Shaft transmission-based engine rotation speed signal simulation system

A technology of engine speed and signal simulation, applied in simulators, general control systems, control/regulation systems, etc., can solve problems such as the inability to effectively verify the correctness of software algorithms, inaccurate transmission ratios, etc., to overcome the uncertainty of transmission ratios , high precision, the effect of preventing injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

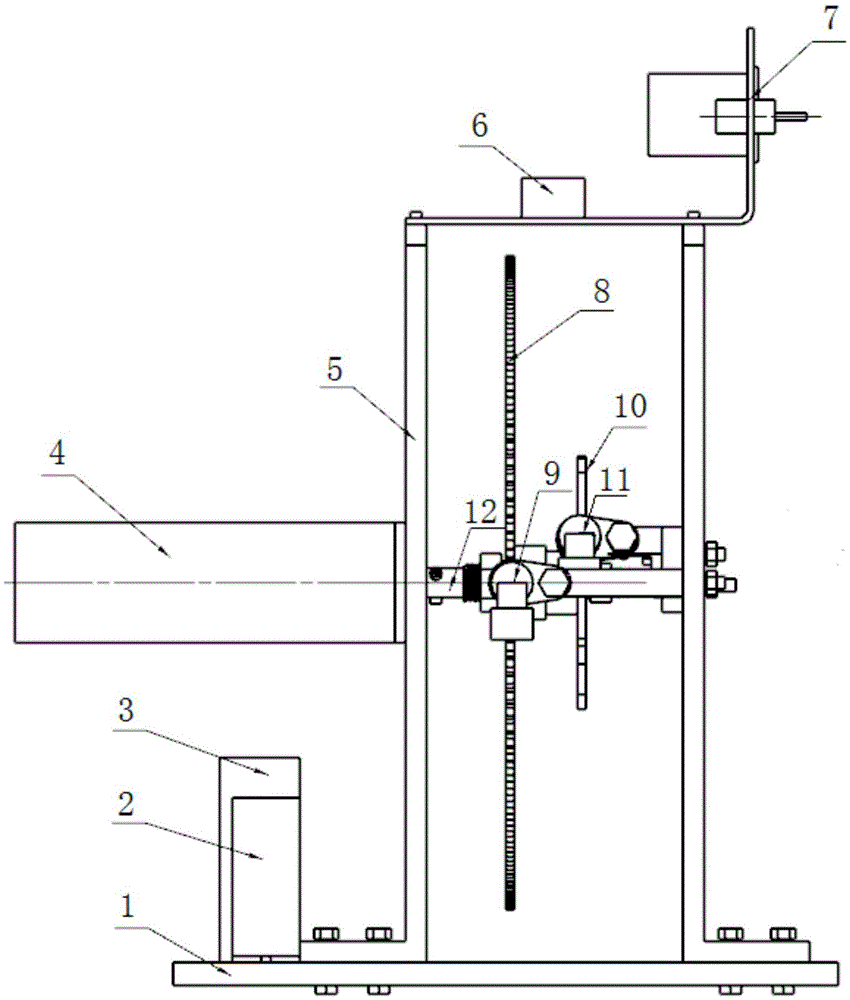

[0026] Such as Figure 1~4 As shown, an engine speed signal simulation system based on shaft transmission includes a mounting base and a drive mechanism installed thereon, a crankshaft signal plate 8, a camshaft signal plate 10, a crankshaft speed sensor 9 and a camshaft speed sensor 11, the The crankshaft speed sensor 9 and the camshaft speed sensor 11 are correspondingly arranged on the sides of the crankshaft signal plate 8 and the camshaft signal plate 10, the system also includes a transmission shaft 12, the drive mechanism is connected to the transmission shaft 12, and the crankshaft signal The disk 8 and the camshaft signal disk 10 are both sleeved on the transmission shaft 12 and fixedly connected with the transmission shaft 12 respectively. The crankshaft speed sensor 9 and the camshaft speed sensor 11 are Hall sensors, which have high measurement accuracy; The driving mechanism drives the transmission shaft 12 to rotate, and then drives the crankshaft signal disk 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com