An insulating test piece and a test electrode device using the insulating test piece

A technology for testing electrodes and test pieces, which is applied in measuring devices, testing dielectric strength, measuring electricity, etc., can solve problems such as partial discharge of insulating test pieces, and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

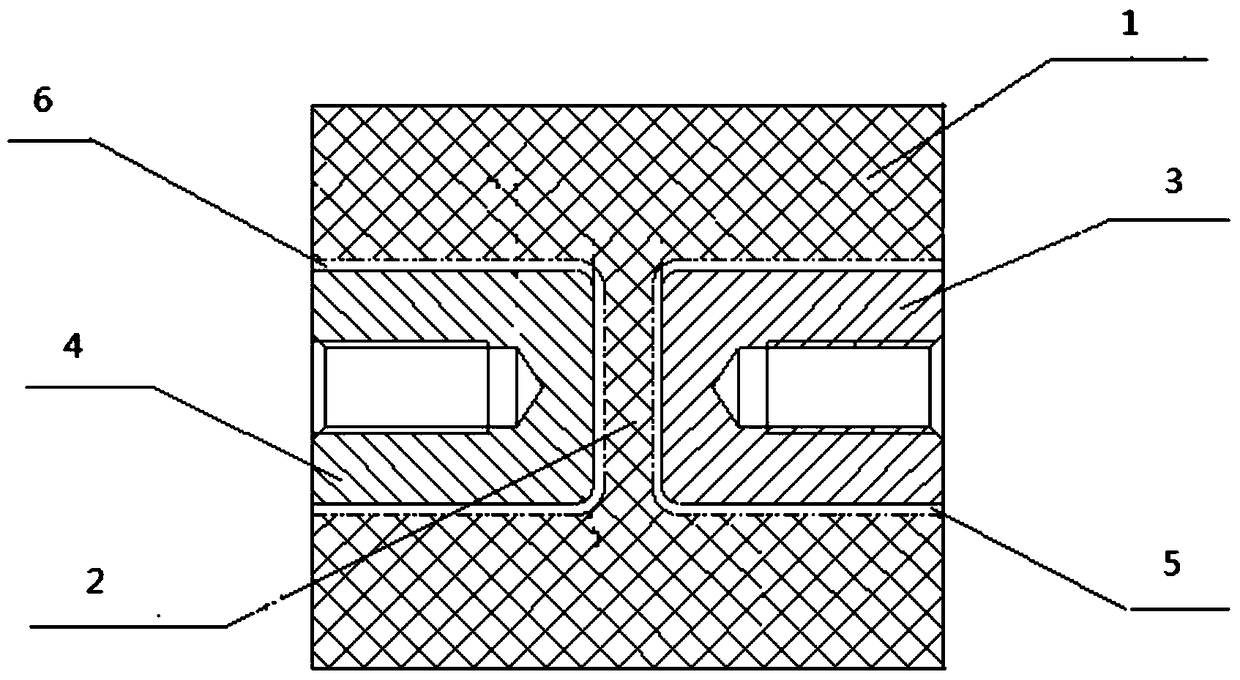

[0021] like figure 1 Shown is a consistent test electrode device, including an insulating test piece, a high-voltage test electrode 3 and a low-voltage test electrode 4, the insulating test piece includes a base 1 made of insulating material to be tested, and a first accommodation groove 5 is provided on one side of the base , the other side of the substrate opposite to the first accommodation groove is provided with a second accommodation groove 6, the first accommodation groove 5 coincides to accommodate the high-voltage test electrode 3, and the second accommodation groove 6 coincides to accommodate the low-voltage test electrode 4; the first accommodation groove and There is an insulating part 2 between the grooves integrally formed with the base body between the second receiving grooves.

[0022] By completely wrapping the test electrode, problems such as partial discharge caused by the structure of the test device body in the existing GB1408 "Electric Strength Test Metho...

Embodiment 2

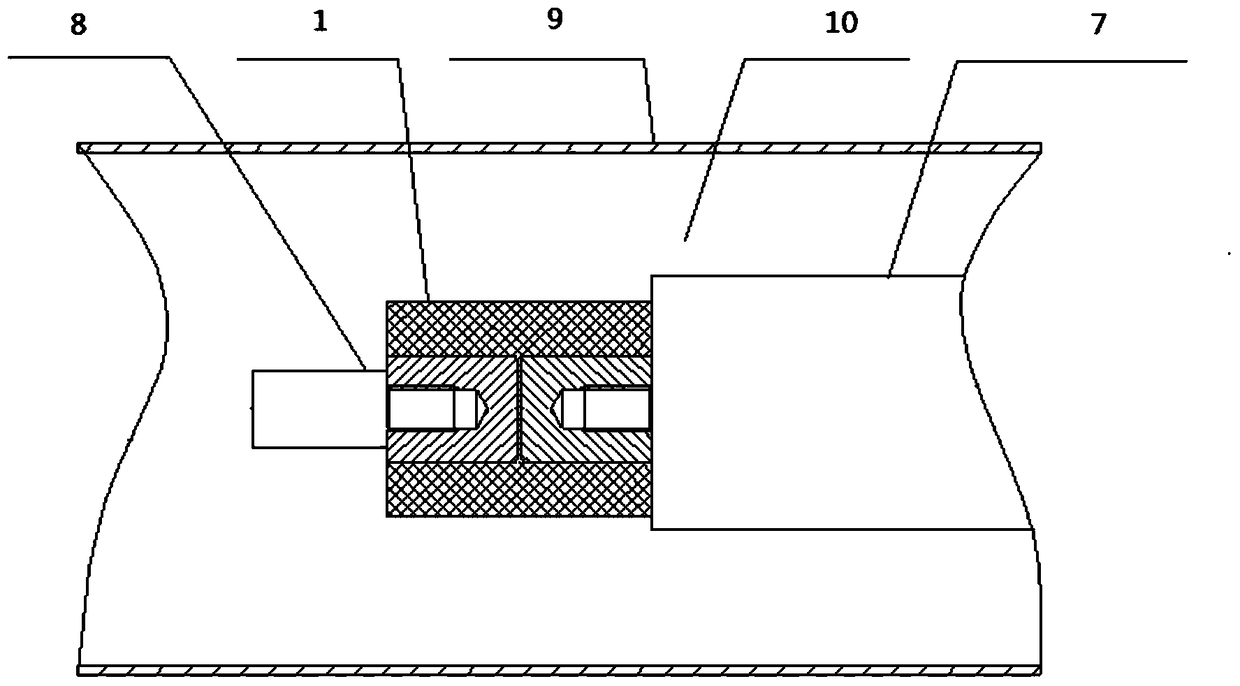

[0032] The difference from Embodiment 1 is that the test electrode device also includes a casing 9 for placing an insulating test piece, and an insulating gas 10 is filled in the casing. The high-voltage electrode is connected to the conductive and supporting component 7 , and the low-voltage electrode is connected to the conductive component 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com