Method for detecting seepage performance of rock with filled connected fracture

A detection method and seepage technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as limited research significance, and achieve the effect of scientific methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for detecting the seepage performance of rock filling through fractures of the present invention is mainly realized through the following technical solutions:

[0040] Step 1: Take the original rock samples to be studied from the underground engineering, and make more than 50 standard specimens for use. The size of the standard specimens is a cylinder with a diameter of 50mm and a height of 100mm. The sample for the seepage orthogonal test, and the remaining part is used as the sample for the full-scale seepage test of the filled through-fracture rock.

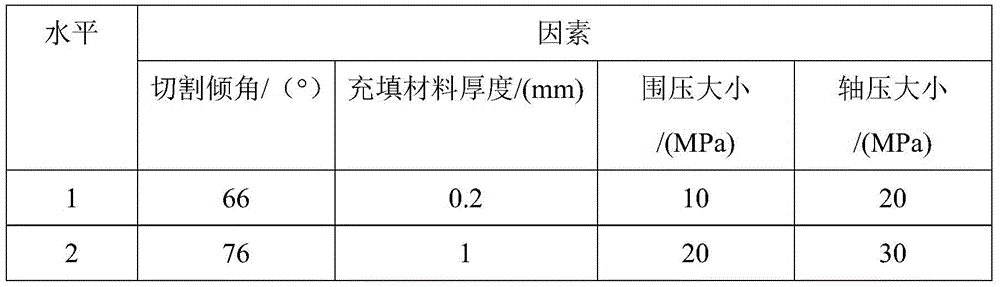

[0041] Step 2: Design an orthogonal test plan for the seepage flow of filling cracks, and take the cutting inclination angle A, the thickness of the filling material B, the confining pressure C, and the axial pressure D as the factors that affect the seepage coefficient of the filling seepage test. According to the experience level of each factor, each Three levels are set for each influencing factor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com