Aircraft engine online oil wear particle imaging counting sensor and manufacturing method

A technology of aircraft engines and counting sensors, applied in instruments, scientific instruments, measuring devices, etc., can solve problems affecting detection, pressure loss, thin oil pipelines, etc., and achieve the effect of no false detection and no pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

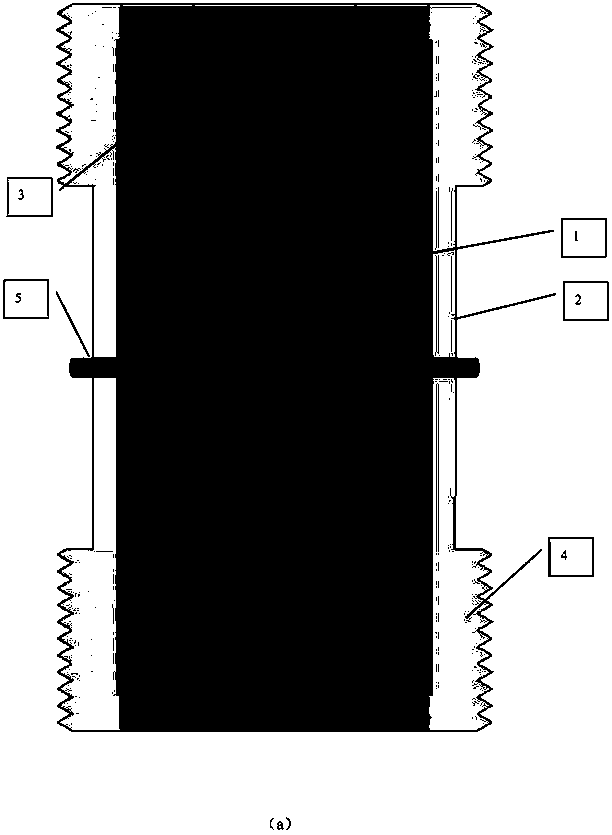

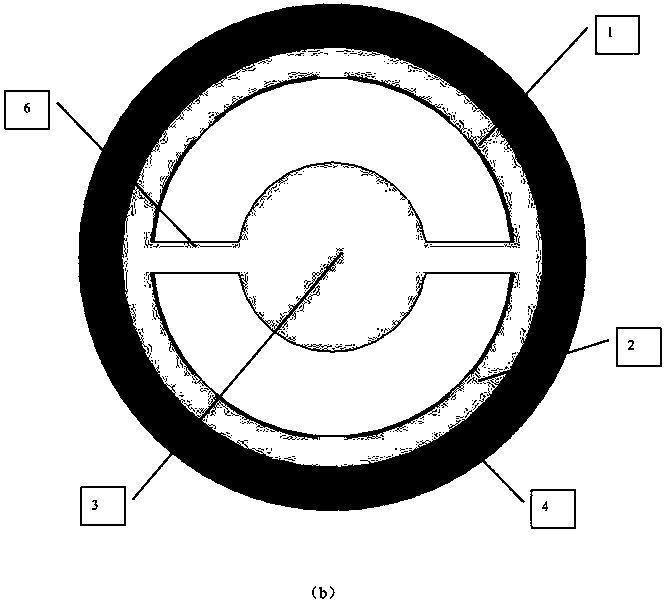

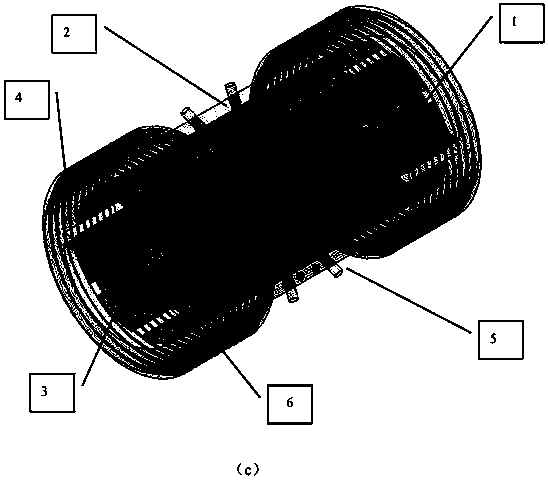

[0040] see figure 1 (a), (b), (c), (d), an aircraft engine online oil wear imaging counting sensor, including: pipeline center (not shown in the figure, known to those skilled in the art). The sensor tube wall 2 is embedded in the center of the pipeline, and the sensor tube wall 2 is circular and concentric with the pipeline center; the sensor core 3 is embedded in the sensor tube wall 2, and a plurality of metal plates 1 are embedded in the sensor tube wall 2 (composed of Multi-pole plate), preferably a plurality of metal pole plates 1 are evenly distributed; the number of metal pole plates 1 is 6 to 14; the sensor tube wall 2 is provided with an interface part 4 and a metal lead 5.

[0041] Among them, the sensor tube wall 2 and the sensor inner core 3 are connected by single point or multiple points, and evenly distributed or non-uniformly distributed, so as to realize the online full flow detection of large flow rate, and can realize the passage and flow of large particles...

Embodiment 2

[0053] For the composite array plate sensor of the electrical tomography imaging system, the general design and manufacturing method does not have the sensor inner core 3, and the metal plate 1 is fixed by bonding, and the metal plate 1 cannot be processed to be consistent with the arc of the sensor tube wall 2, and the surface The shape with high finish has low dimensional accuracy and cannot meet the requirements of long-term high-temperature operation. According to the existing design and manufacturing methods, the manufactured sensors cannot achieve the consistency of parameter processing, nor can they meet the requirements of high temperature operation.

[0054] For this reason, the embodiment of the present invention adopts different technological methods——3D printing, a method combined with mold opening and injection molding for secondary processing. Among them, the 3D printing method is a new type of complex structure processing method, which has been maturely applied ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com