Calcium carbide cooling device and method

A cooling device, calcium carbide technology, applied in transportation and packaging, processing discharged materials, furnaces, etc., can solve the problems affecting the safe and stable operation of the cooling system, increasing the system investment cost, unstable chemical properties, etc. Economical, improved operational safety, and reduced time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

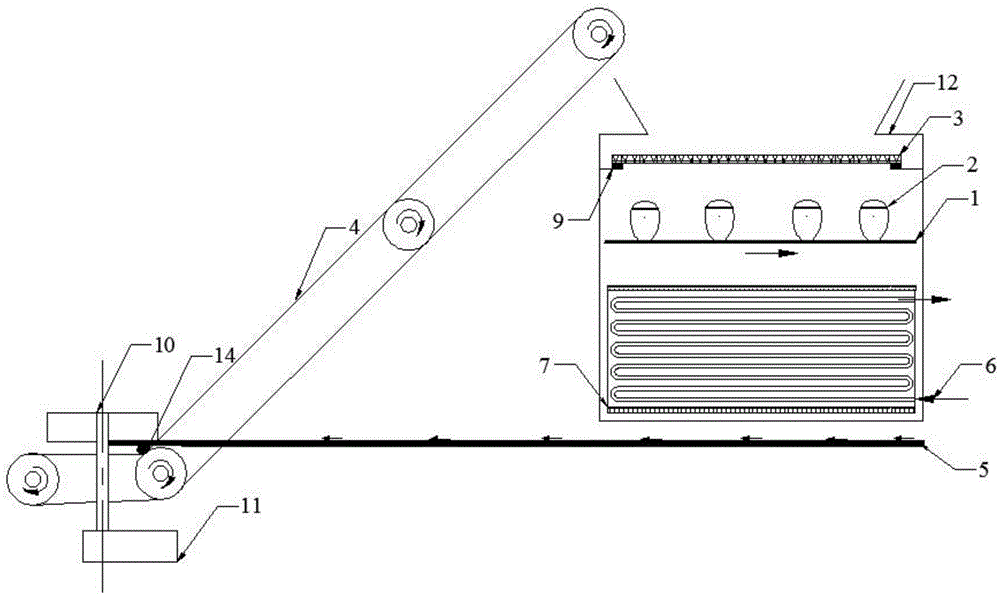

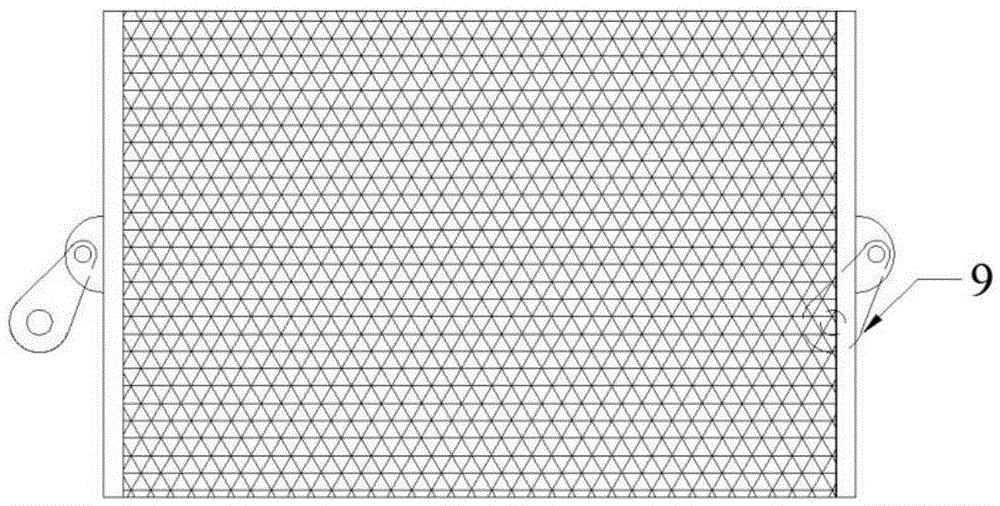

[0038] see figure 1 and figure 2 , the present invention comprises calcium carbide cooling tower 12, and the upper end of calcium carbide cooling tower 12 is provided with sand inlet, and the lower end is provided with sand outlet, and in calcium carbide cooling tower 12, is provided with heat exchanger 7, cooling pan track 1 and can Screen 3 vibrating in the horizontal plane. The sand inlet and sand outlet of the calcium carbide cooling tower 12 are connected with the sand transfer system to form a sand transfer loop.

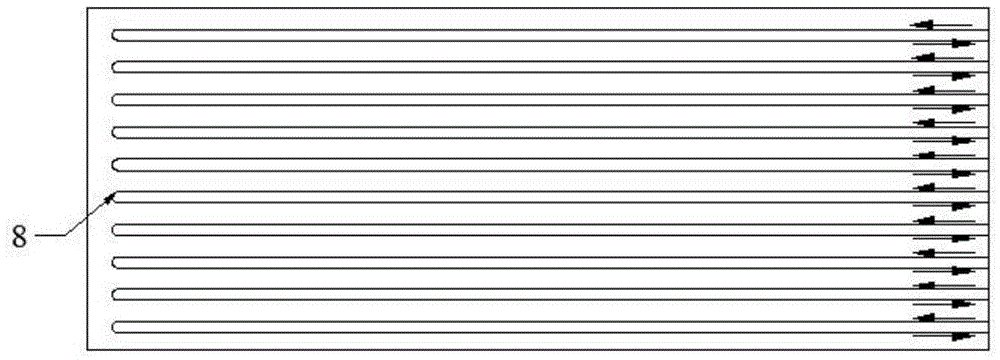

[0039] The heat exchanger 7 includes several rows of heat exchange tubes 8 and filter screens installed on the upper and lower sides of the heat exchange tubes 8. The filter screens are mainly used to make the sand flow down and evenly distribute through the heat exchange tubes 8; the heat exchange tubes 8 The material is steel; the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com