Segmental fire power adjusting device

An adjustment device and a segmented technology, which is applied in the field of segmented fire power adjustment devices, can solve the problems of uncontrollable rotation speed, flame extinguishing, uneven flame temperature, etc., and achieve the effects of avoiding flame extinguishing, ensuring normal use, and uniform flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

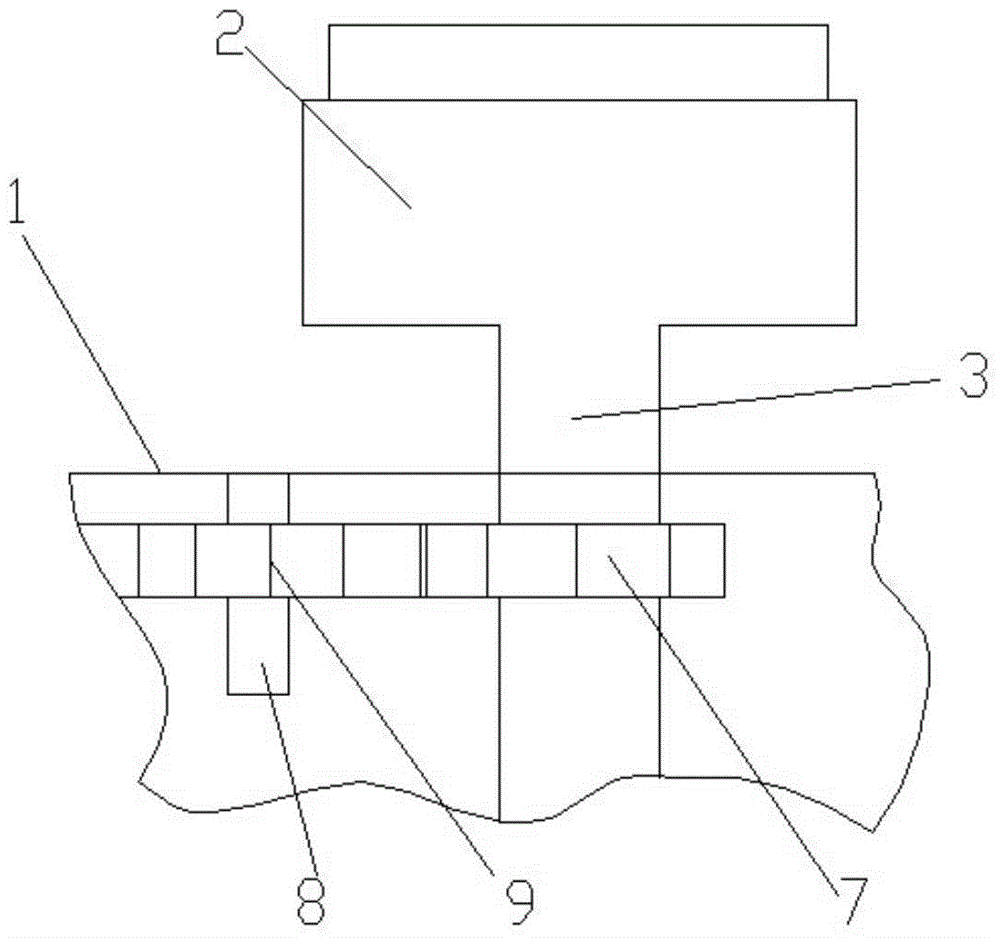

[0015] Embodiment one: (as Figure 1-2 ) A segmented fire power adjustment device, including a gas stove body 1 and a knob 2, the knob can control the gas stove on and off and adjust the firepower, the rotary rod 3 of the knob is located inside the gas stove body, and The fire power adjustment device is consistent with the existing operation mode in the ignition state. After confirming that the ignition is working normally, it will play a regulating role. It also includes the control that the knob can be adjusted to the designated area after the ignition flame works normally, and the rotation speed of the knob is controlled in steps. device. When igniting, the rotation of the knob is not affected by the step-type control device. After confirming the ignition, use the step-type control device to make the knob rotate in steps when adjusting the firepower, rather than a smooth and unobstructed rotation. Turn it down in the clockwise direction When the fire is on, the rotation sp...

Embodiment 2

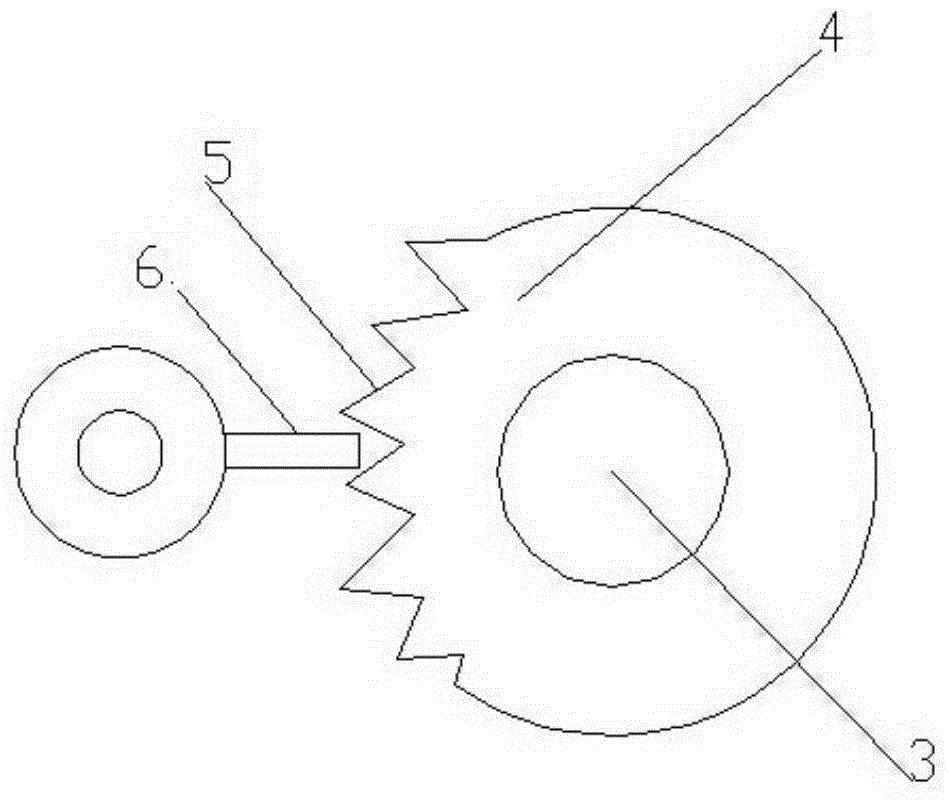

[0018] Embodiment two: (as Figure 3-4 ) The structure of the control device capable of adjusting the knob to a designated area and the rotation speed of the knob is a stage type is: a first gear 7 is fixedly positioned on the rotary rod, and a support rod 8 is fixed inside the gas stove body. A second gear 9 is fixed on the support rod, and the teeth of the first and second gears can be squeezed and crossed in the direction of motion. The knob drives the rotary rod to rotate, and the first gear rotates together with the rotary rod, and the teeth of the first and second gears can squeeze and cross each other in the direction of motion, thereby realizing the segmental rotation of the knob. Of course, the sizes of the first and second gears can be adjusted accordingly according to actual needs.

Embodiment 3

[0019] Embodiment three: (as Figure 5-6 ) The structure of the control device capable of adjusting the knob to a designated area and the rotation speed of the knob is a stage type is as follows: an L-shaped shrapnel 10 is fixed inside the gas stove body, and a number of notches 11 are evenly spaced on the rotary rod. The horizontal straight portion of the L-shaped elastic piece and the notch block each other in the moving direction and can climb over each other, and the notch is just for the horizontal straight portion of the L-shaped elastic piece to be placed. The knob drives the rotary rod to rotate. In the initial state, the straight part of the L-shaped shrapnel is inserted into the gap. With the rotation of the rotary rod, the gap rotates, and the straight part of the L-shaped shrapnel blocks the rotation direction of the notch. When the notch rotates When reaching a certain level, the straight and horizontal portion of the L-shaped shrapnel produces elastic deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com