Fuel feeding method for high-thermal-efficiency wood-granule burning fireplace

A technology with high thermal efficiency and wood pellets, which is applied in the direction of solid heating fuel, household stove/stove, lighting and heating equipment, etc. It can solve the problems of being unable to meet the needs of use in places without power supply, so as to meet the use of places without power supply and expand the use The effect of the place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

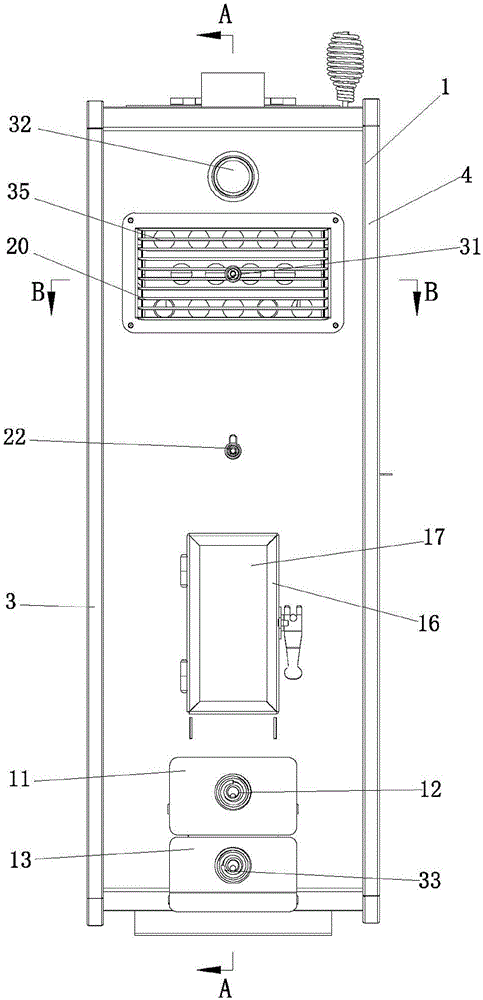

[0025] Refer to attached Figure 1~5 , a fuel supply method for a high thermal efficiency wood pellet fireplace, the high thermal efficiency wood pellet fireplace includes a furnace body 1, a discharge system, a smoke exhaust system, a grate device, a ventilation system and a heating system, the The furnace body 1 is a hollow structure, the furnace body 1 is provided with a furnace 2, the furnace grate device is arranged in the furnace 2, and the discharge system is located in the furnace body 1 and is positioned above the furnace grate device; the discharge system adopts The unpowered discharge device 37 is used for feeding, and the discharge device 37 adopts a funnel-shaped structure. 2. Above the inner grate device, the wood pellets entering the discharge device 37 are automatically fed into the grate device in the furnace 2 for combustion und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com