A real-time monitoring system for combustion conditions of gas-fired boilers

A gas-fired boiler, real-time monitoring technology, applied in the control system, steam generation, lighting and heating equipment, etc., can solve problems such as adjustment, users cannot obtain boiler efficiency data in real time, and no system or product is found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

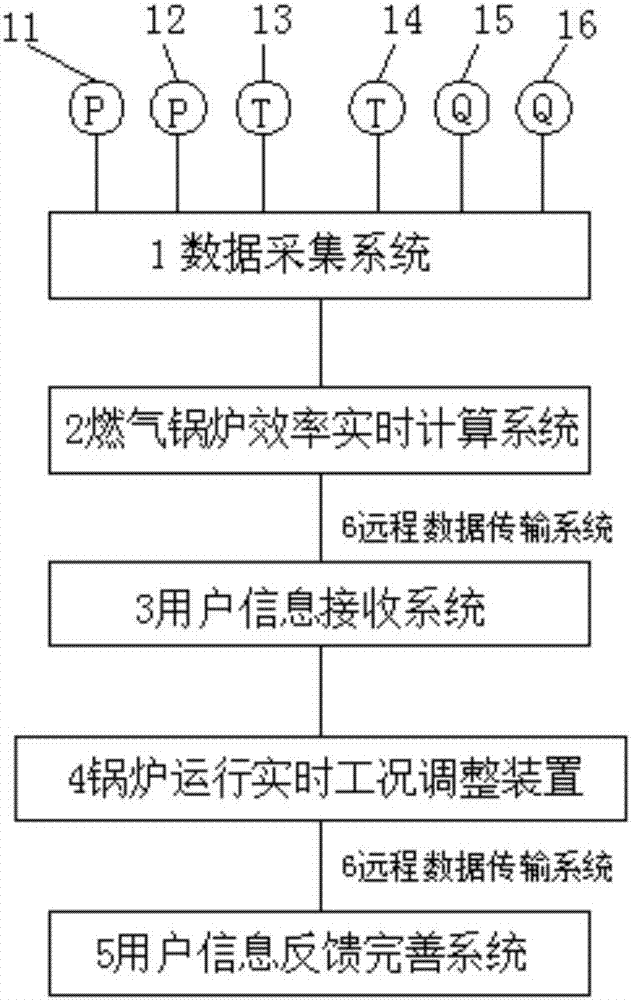

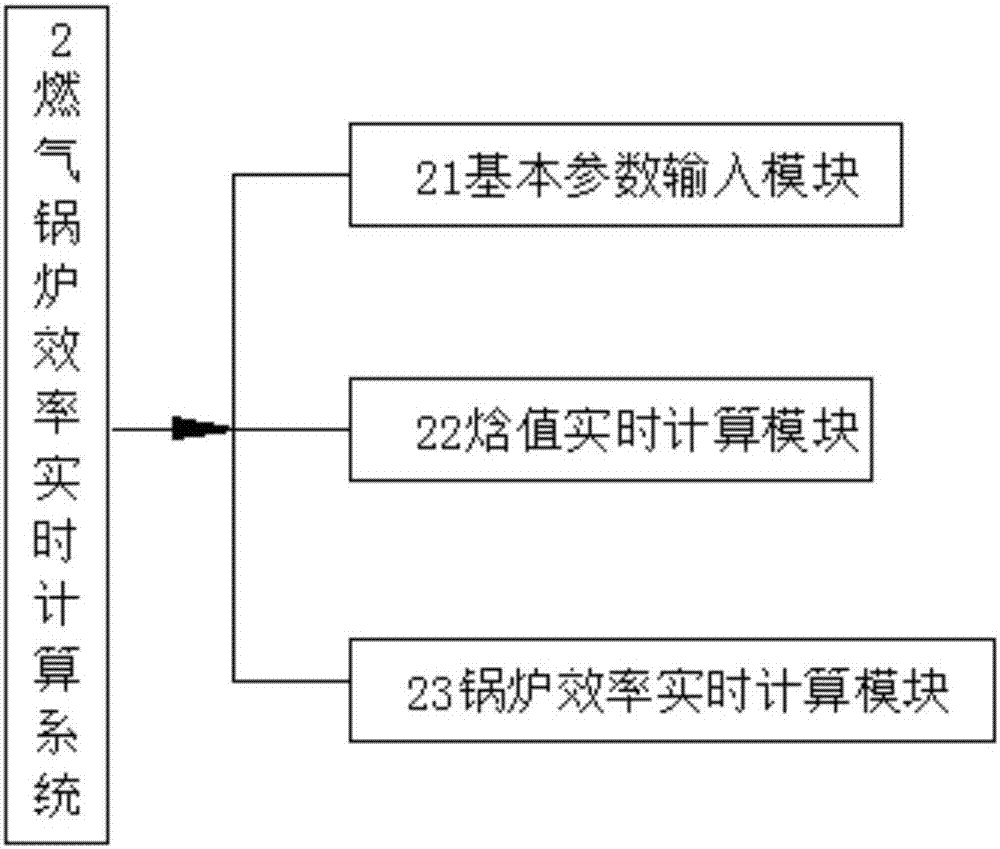

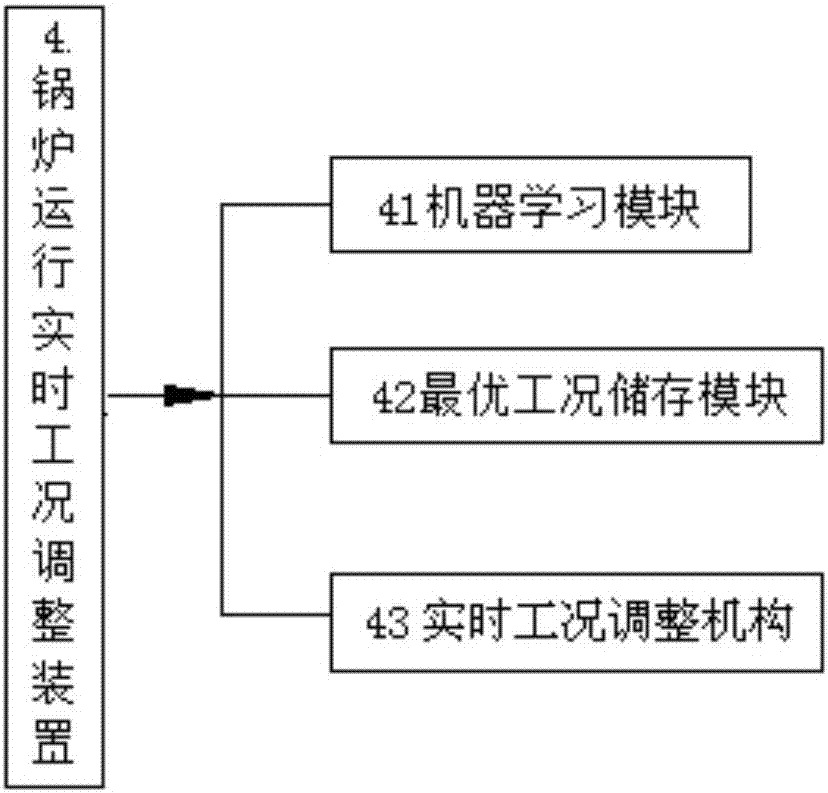

[0028] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the gas boiler combustion working condition real-time monitoring system of the present invention mainly includes a data acquisition system 1, a gas boiler efficiency real-time calculation system 2, a user information receiving system 3, a boiler operation real-time working condition adjustment device 4, and a user information feedback improvement system 5 and remote data transmission system 6, wherein:

[0029] The data acquisition system 1 has the functions of measuring boiler feed water temperature, steam temperature, gas pressure, steam pressure, gas flow and steam flow, and mainly includes a boiler feed water temperature sensor 11, a steam temperature sensor 12, a gas pressure sensor 13, a steam Pressure sensor 14, gas flow sensor 15 and steam flow sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com