Fisher

An overshot and detent technology, which is applied in the field of drilling and production equipment, can solve the problems of restricting the progress of the project and construction time, the force and fracture of the cable, and the complication of accidents, so as to achieve the controllable salvage process, improve the success rate, and improve the salvage ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

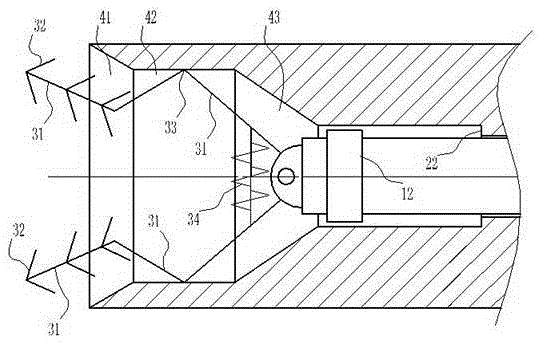

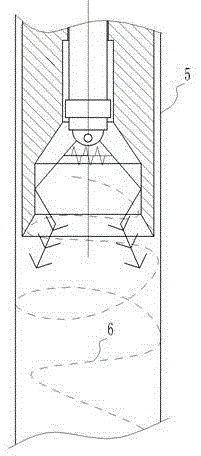

[0036] Overshot of the present invention, its overall structure is as figure 1 As shown, it includes a connecting rod 1, which is covered with an outer sleeve 2 that can slide in both directions. The end of the connecting rod 1 is provided with a set of pawls 3 that can be opened and closed radially. When the outer sleeve 2 moves away from When the ratchet 3 moves in the direction, the ratchet 3 can be disengaged from the inner cavity 4 of the outer sleeve 2 and opened, and when the outer sleeve 2 moves in the direction of the ratchet 3, the ratchet 3 can be closed and stored in the outer sleeve 2 in the lumen 4. Its opening and closing process is as follows: Figure 4 , Figure 5 , Image 6 shown.

[0037] The outer sleeve 2 of this embodiment adopts a thick-walled design and has a relatively large dead weight. The overshot can conveniently and quickly fish out the well falling objects of oil and gas drilling and production. Positioning and judgment of falling objects i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com