PDC drill bit applicable to core drilling of moon

A drill bit and coring technology, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as difficulty in cutting cuttings discharge, increase drilling failures, and increase working time, so as to achieve smooth cuttings discharge and improve coring efficiency. , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

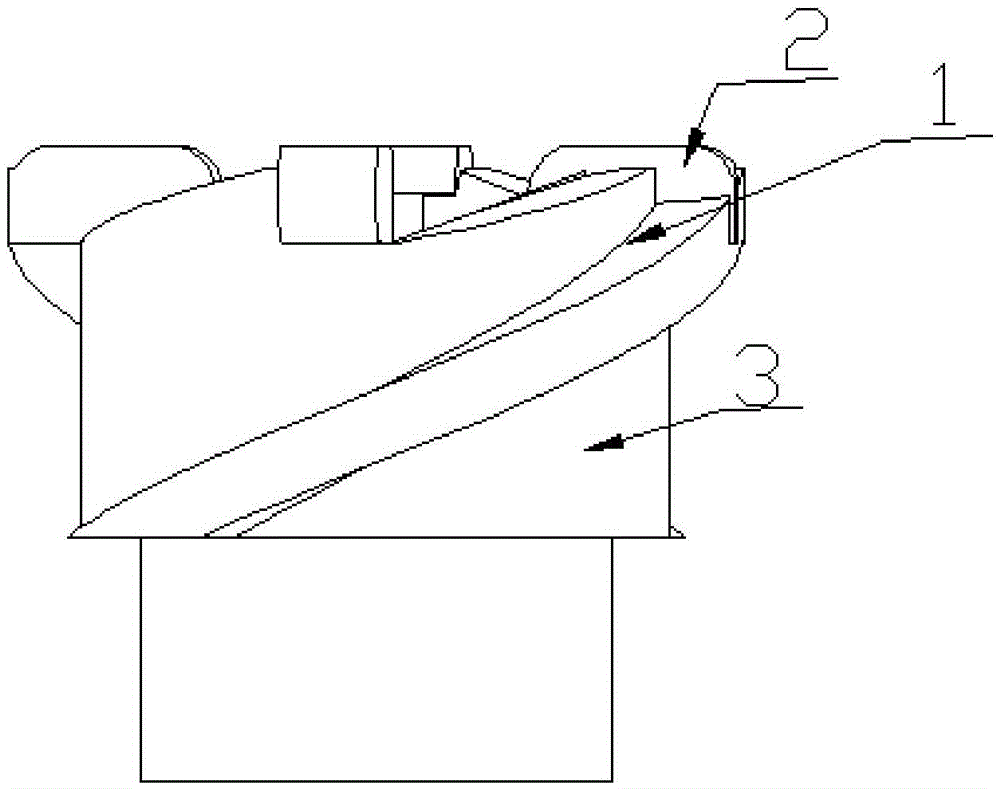

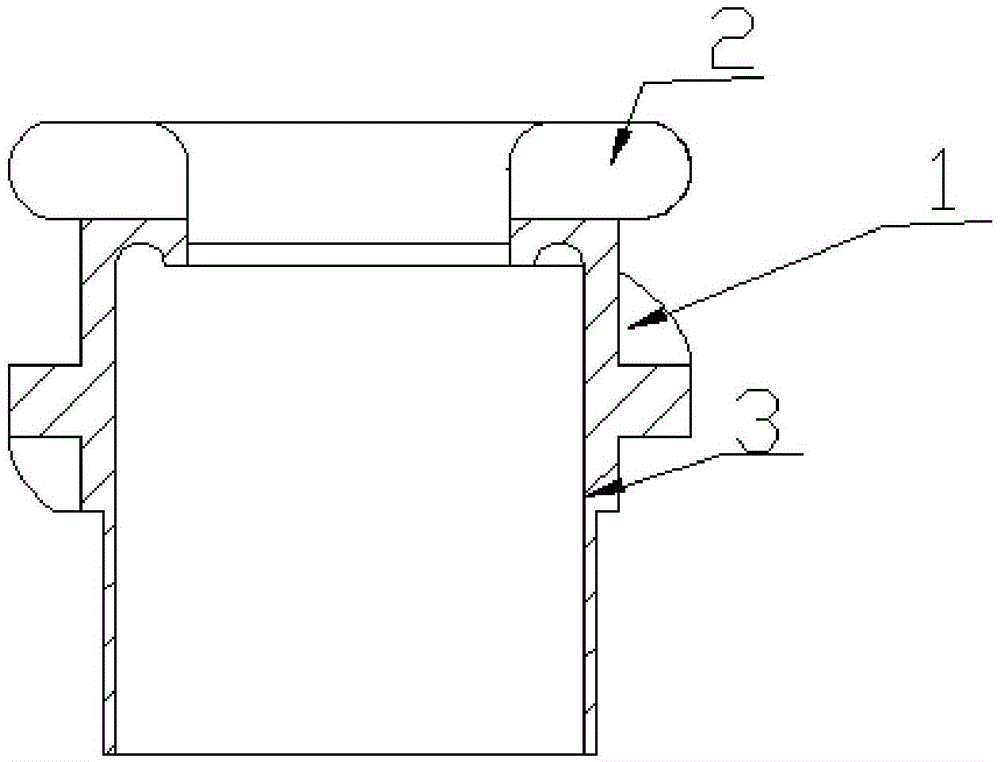

[0012] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0013] The present invention is applicable to a PDC bit for lunar drilling and coring. It consists of a bit matrix, a PDC cutting tooth and a spiral cuttings channel. The PDC cutting teeth 2 are symmetrically welded on the front part of the drill bit matrix 3. It is two helical grooves 1 that spirally rise along the outer peripheral wall of the drill matrix 3 and are welded with the outer peripheral wall. The lower ports 1-1 of the two helical grooves are connected with the PDC cutting teeth 2 correspondingly, and the upper ports 1-2 are In the cuttings discharge port, the two spiral grooves 1 are made of wear-resistant materials.

[0014] The helix angle of the spiral cuttings channel 1 is 19-22 degrees.

[0015] The present invention is used for the helical cuttings channel of the PDC bit for lunar drilling and coring, and is adapted to the PDC bit, and is not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com