Torque overload protection tool

An overload protection and tool technology, which is applied in drilling equipment, earthmoving, driving devices for drilling in wellbore, etc. The effect of meeting the needs of on-site use, saving tripping time, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

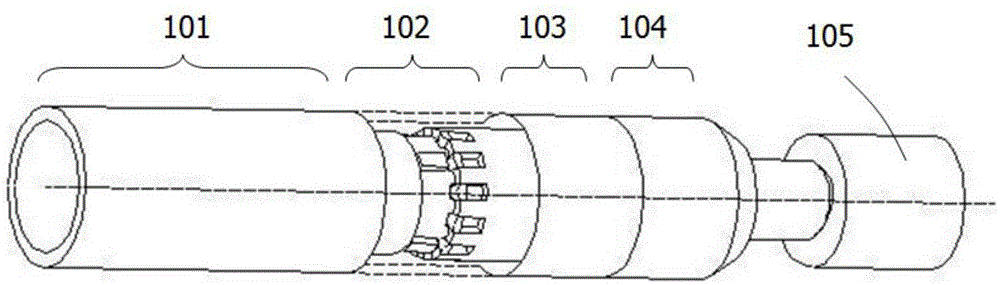

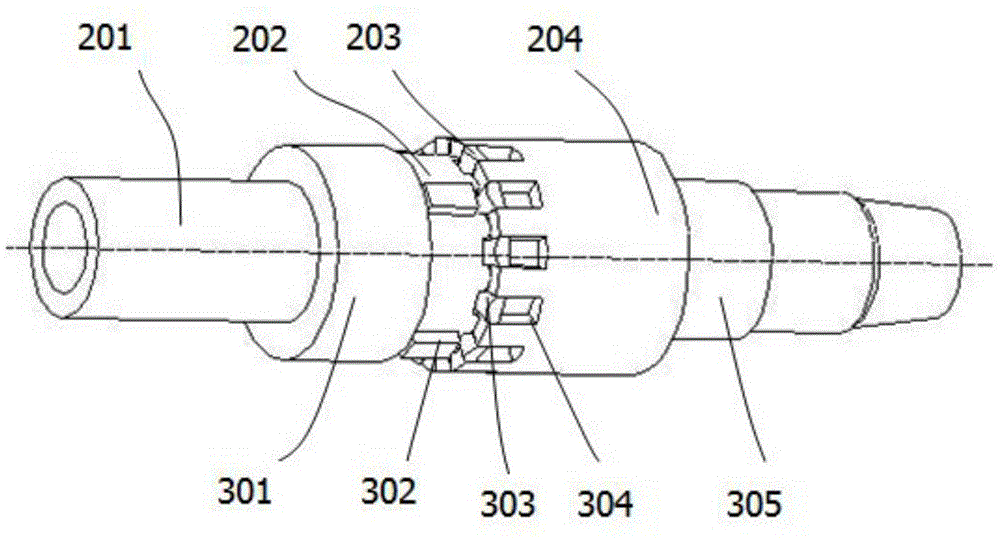

[0040] Such as Figure 1 to Figure 12 As shown, the overload protection device 102 is composed of an upper spline 202 , a driving spline 203 , a lower spline 1 204 and a spring 205 . Among them, the upper spline 202, the transmission spline 203, the lower spline 1 204 and the spring 205 are all coaxial with the central shaft 201, and one end is in contact with the step of the central shaft 201, and the other end is matched with the transmission spline 203, and the transmission spline 203 cooperates with lower spline one 204. The step A301 of the central shaft 201 restricts the upper spline 202 to move leftward along the central shaft 201, and the lock nut 405 matched with the thread A305 restricts the lower spline 1 204 to move rightward along the central shaft 201, and provides spring 205 with initial compressive force.

[0041] The power outer cylinder 101 is equivalent to the load input shaft and is connected with the upper drill string; the bearing assembly 103 is used to ...

Embodiment 2

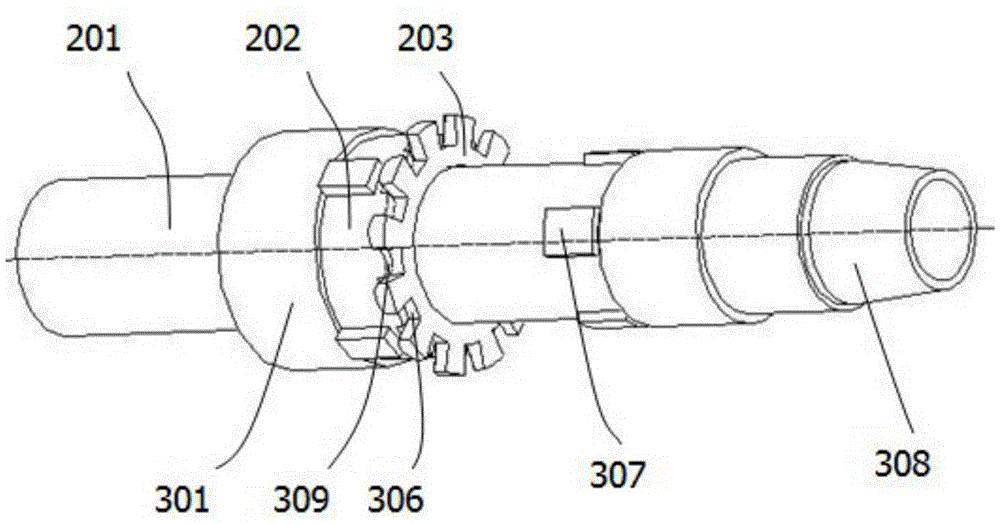

[0055] Such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 12 As shown, the overload protection device 102 is composed of an upper spline 202 , a lower spline 2 206 and a spring 205 . Among them, the upper spline 202, the second spline 206 and the spring 205 are all coaxial with the central shaft 201, and one end is in contact with the step of the central shaft 201, and the other end is matched with the transmission spline 203, and the transmission spline 203 and the lower spline Two 206 cooperation. The step A301 of the central shaft 201 restricts the upper spline 202 to move leftward along the central shaft 201, and the locking nut 405 matched with the thread A305 restricts the lower spline 2 206 to move rightward along the central shaft 201, and provides spring 205 with initial compressive force.

[0056] The power outer cylinder 101 is equivalent to the load input shaft and is connected with the upper drill string; the bearing assembly 103 is used to bear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com