A kind of stationary gas engine oil composition

A gas engine and oil composition technology, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems that the clean and dispersible properties of oil products cannot meet the requirements, and the viscosity stability of oil products cannot be guaranteed, so as to maintain clean and dispersible properties , strong operability and obvious technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The composition preparation scheme is shown in Table 1.

[0046] Table 1 Examples of Lubricating Oil Compositions

[0047]

[0048] Table 2 compound agent components

[0049]

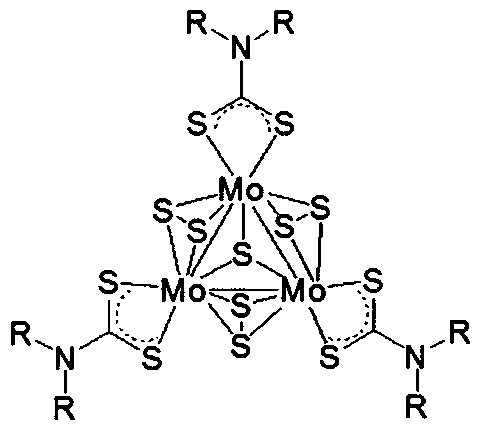

[0050] Note ①: The structure of non-phosphorus molybdenum salt friction reducer is shown in the following formula:

[0051]

[0052] R is pentyl.

[0053] Note ②: The structure of non-phosphorus molybdenum salt friction reducer is shown in the following formula:

[0054]

[0055] R is heptyl.

[0056] Table 2 Lubricating Oil Composition Example Viscosity Test Comparison

[0057]

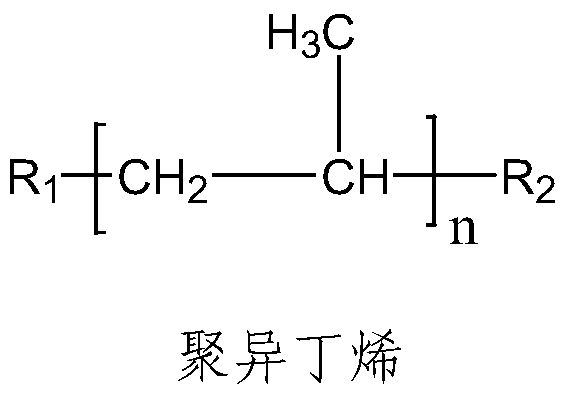

[0058] As can be seen from Table 2, the order of viscosity from large to small is Comparative Example 3>Example 2>Comparative Example 2>Example 1>Comparative Example 1, and the viscosity of Example 1 and Example 2 are all due to the addition of polyisobutylene. promoted.

[0059] Table 3 Lubricating Oil Composition Example Viscosity Index Test Comparison

[0060]

[0061] It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com