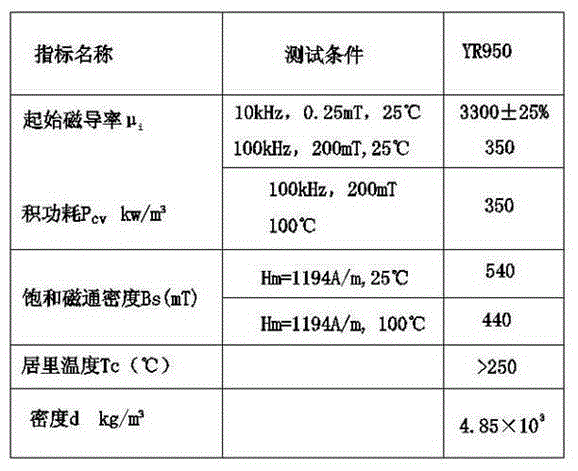

YR950 wide-temperature high-direct-current-superposition low-power-consumption manganese-zinc ferrite material and preparation method thereof

A high DC superposition, ferrite material technology, applied in the field of inductance transformers and communications, can solve the problem of low power consumption, achieve the effect of reducing loss, stable production process, wide temperature DC superposition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

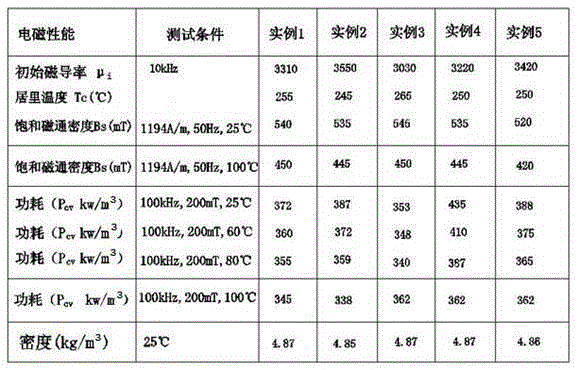

Examples

Embodiment 1

[0035] Selection of raw materials: Industrial pure Fe 2 o 3 , MnO, ZnO and CaCO above chemical purity 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO 2 Wait.

[0036] Component design of ferrite material:

[0037] The ferrite material in the present embodiment is made of main ingredient and auxiliary ingredient, wherein, the main ingredient is made of 54.8mol% Fe 2 o 3 , 38.4mol% of MnO and 6.8mol% of ZnO, the auxiliary component is composed of CaCO 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO 2 composition, and CaCO 3 The dosage is 0.025wt% of the main material, SiO 2 The dosage is 0.003wt% of the main material, V 2 o 5 The amount of the main material is 0.020wt%, Co 2 o 3 The dosage is 0.150wt% of the main material, TiO 2 The consumption of NiO is 0.150wt% of the main material, and the consumption of NiO is 0.500wt% of the main material.

[0038] In this embodiment, the preparation method of the YR950 wide-temperature, high-DC superimposed low-power mangan...

Embodiment 2

[0050] Selection of raw materials: Industrial pure Fe 2 o 3 , MnO, ZnO and CaCO above chemical purity 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO 2 Wait.

[0051] Component design of ferrite material:

[0052] In this embodiment, the ferrite material is made of a main ingredient and an auxiliary ingredient, wherein the main ingredient is made of 54.5mol% Fe 2 o 3 , 38.4mol% of MnO and 7.1mol% of ZnO, the auxiliary component is composed of CaCO 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO 2 composition, and CaCO 3 The dosage is 0.025wt% of the main material, SiO 2 The dosage is 0.003wt% of the main material, V 2 o 5 The amount of the main material is 0.020wt%, Co 2 o 3 The dosage is 0.150wt% of the main material, TiO 2 The consumption of NiO is 0.150wt% of the main material, and the consumption of NiO is 0.500wt% of the main material.

[0053] The preparation method of YR950 wide temperature high DC superimposed low power manganese zinc ferrite material i...

Embodiment 3

[0055] Selection of raw materials: Industrial pure Fe 2 o 3 , MnO, ZnO and CaCO above chemical purity 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO 2 Wait.

[0056] Component design of ferrite material:

[0057] In this embodiment, the ferrite material is made of a main ingredient and an auxiliary ingredient, wherein the main ingredient is made of 55.1mol% Fe 2 o 3 , 38.4mol% of MnO and 6.5mol% of ZnO, the auxiliary component is composed of CaCO 3 , SiO 2 , V 2 o 5 、Co 2 o 3 , NiO and TiO2 composition, and CaCO 3 The dosage is 0.025wt% of the main material, SiO 2 The dosage is 0.003wt% of the main material, V 2 o 5 The amount of the main material is 0.020wt%, Co 2 o 3 The dosage is 0.150wt% of the main material, TiO 2 The consumption of NiO is 0.150wt% of the main material, and the consumption of NiO is 0.500wt% of the main material.

[0058] The preparation method of YR950 wide temperature high DC superimposed low power manganese zinc ferrite material in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com