Preparation method of tungsten-doped vanadium dioxide superfine powder

An ultra-fine powder, vanadium dioxide technology, applied in vanadium oxide and other directions, can solve the problems of easy introduction of impurities, increase production cost, etc., and achieve the effects of improving preparation efficiency, increasing comfort, and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

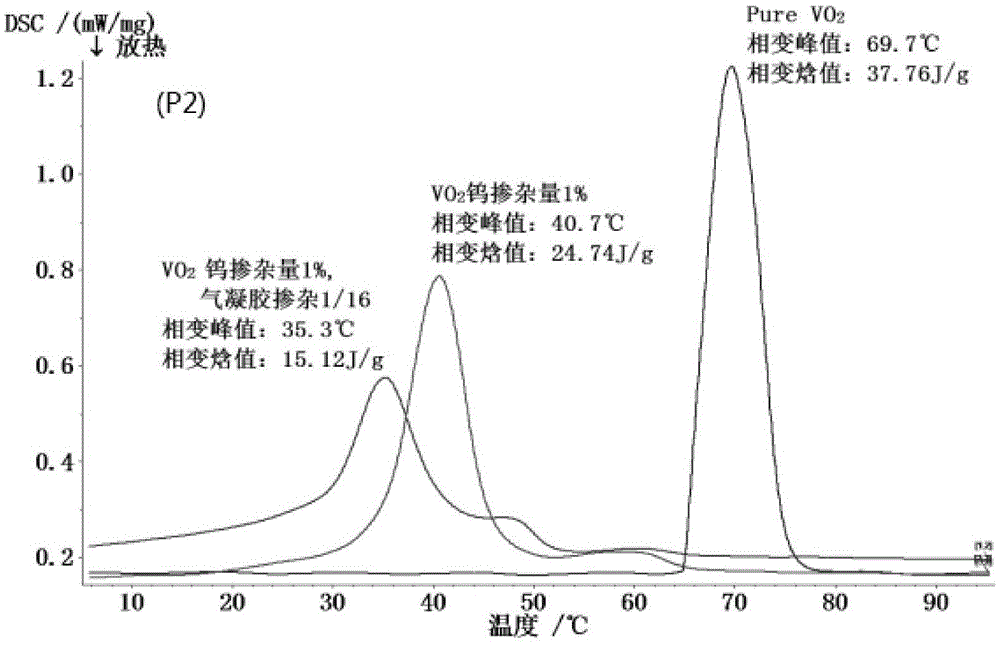

Image

Examples

preparation example Construction

[0033] A method for preparing tungsten-doped vanadium dioxide ultrafine powder, comprising the following steps:

[0034] Step 1: Preparation of tungsten-doped precursor

[0035] Vanadyl sulfate trihydrate VOSO 4 ·3H 2 O was dissolved in distilled water, and at the same time, soluble hexavalent tungsten compounds accounting for 0.1-5% of the total molar amount of vanadium elements were added and stirred evenly, then an alkaline solution was added, and the pH of the solution was slowly adjusted to 6-7 to obtain an off-white suspension; The suspension is filtered and cleaned to obtain an amorphous tungsten-doped precursor; the tungsten-doped precursor is put into a vacuum drying oven for drying, the drying temperature is 60-80°C, and the drying time is 24-48 hours. Agglomerated tungsten-doped precursor powder, the mesh number of the obtained tungsten-doped precursor powder is greater than 1000 mesh. The soluble hexavalent tungsten compound used is one or more of sodium tungsta...

Embodiment 1

[0045] A method for preparing tungsten-doped vanadium dioxide ultrafine powder, comprising the following steps:

[0046] Step 1: Preparation of tungsten-doped precursor

[0047] Vanadyl sulfate trihydrate VOSO 4 ·3H 2 O was dissolved in distilled water, and at the same time, a soluble hexavalent tungsten compound accounting for 1% of the total molar mass of vanadium was added and stirred evenly, and 0.01mol / L dilute NaHCO 3 The solution was added dropwise to the constantly stirring VOSO at a rate of 50mL / h using a syringe pump. 4 In the solution, control the pH value range from 6 to 7 to obtain an off-white suspension; filter and wash the suspension to obtain an amorphous tungsten-doped precursor; put the tungsten-doped precursor into a vacuum drying oven for drying, and the drying temperature The temperature is 80°C, and the drying time is 24 hours to obtain dry, loose, non-caking tungsten-doped precursor powder, and the mesh number of the obtained tungsten-doped precursor p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com