Uniaxial move multi-track parallel independent type 3D printing device and printing method

A 3D printing and printing device technology, which is applied in the field of single-axis moving multi-track parallel independent 3D printing devices, can solve the problems of low printing accuracy, low working efficiency of a single print head, and inability to meet the construction needs of large-scale buildings. Achieve the effect of improving work efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

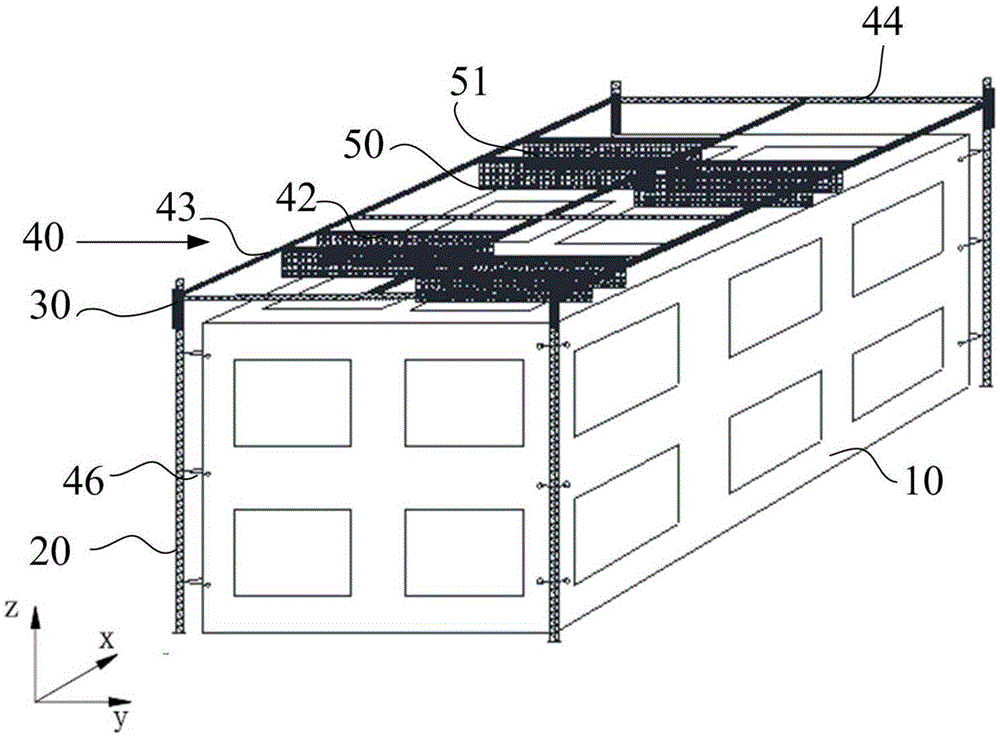

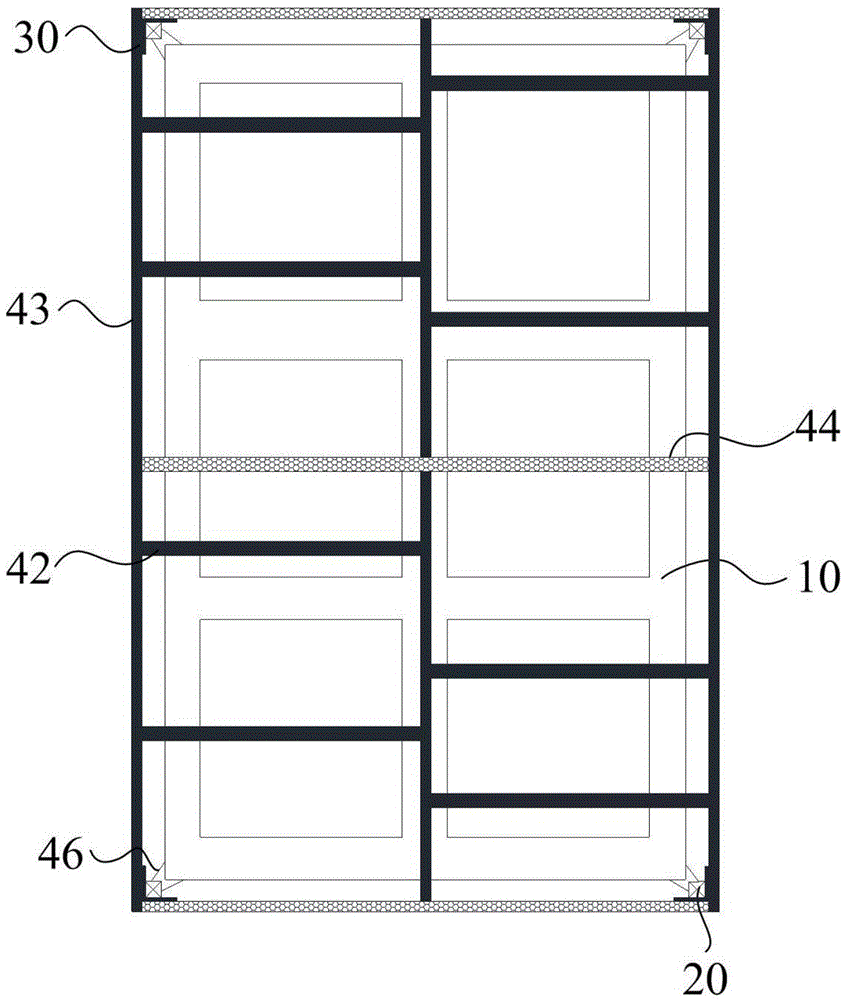

[0027] The single-axis moving multi-track parallel independent 3D printing device of the present invention belongs to one of the block distributed 3D printing devices. Combine below Figure 1 to Figure 4 The single-axis mobile multi-track parallel independent 3D printing device of the present invention is described. In this embodiment, the 3D printing construction of a large-scale building is taken as an example. In order to clarify the direction relationship, the z-axis direction is set as the printed building 10 as required. The xyz rectangular coordinate system of the height extension direction.

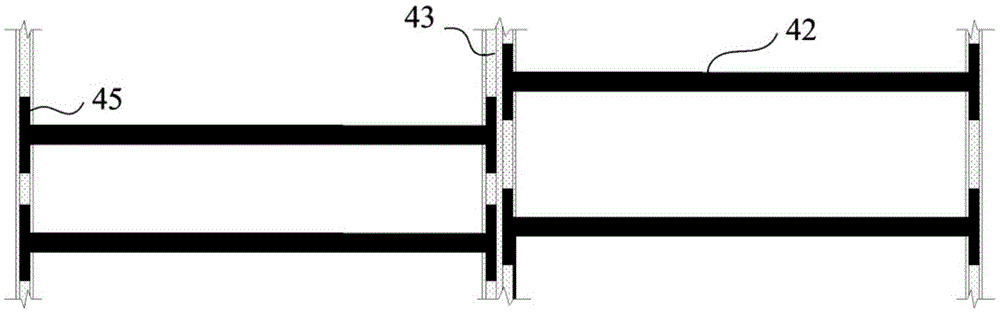

[0028] Please refer to Figure 1 to Figure 4 , the above-mentioned single-axis moving multi-track parallel independent 3D printing device includes a climbing device (not shown) and a printing device 40. The climbing device includes a climbing guide 20 attached to the external facade of the printed building 10 and capable of climbing along the The guide rail 20 is a climbing memb...

Embodiment 2

[0036] combine Figure 1 to Figure 4 The printing method of the single-axis mobile multi-track parallel independent 3D printing device of the present invention is described. In this embodiment, the construction of a building with an elevation above ±0.000 is taken as an example, and the specific steps are as follows:

[0037] S001: Install a single-axis moving multi-track parallel independent 3D printing device, so that the track frame is stably attached to the outer facade of the printed building 10, so that the print head 50 of the printing device 40 is located at an appropriate height above the printed building 10, and in the initial position;

[0038] S002: Send a control command to the printing device 40 through the power control system to move the print head beam 42 along the track beam 43, and at the same time make the print head 50 densely arranged at the lower end of the print head beam 42 eject building materials. Move once to complete the printing construction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com