Thin film feeding and shredding device

A shredding device and film technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of low shredding efficiency, material blocking and jamming, poor shredding effect, etc., and achieve high shredding efficiency, Easy disassembly and assembly, good shredding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

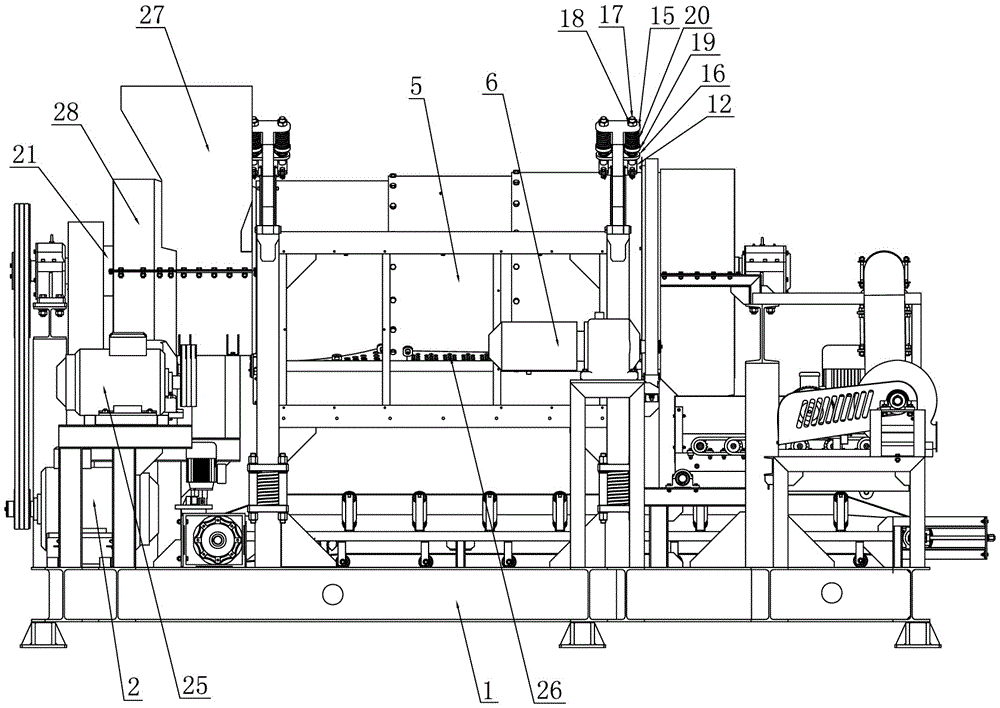

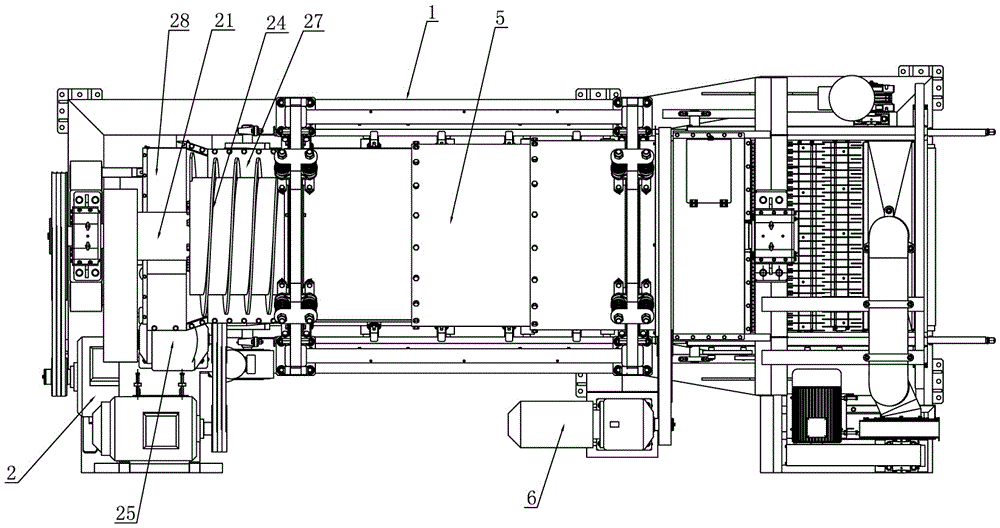

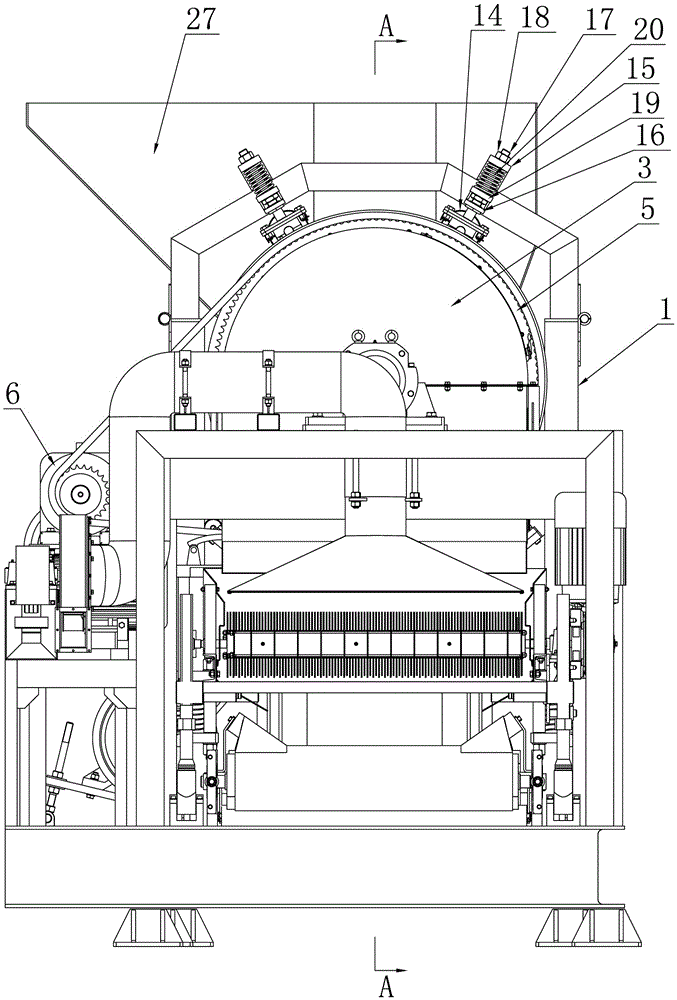

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, the film feeding and shredding device includes: a frame 1, a main shaft 21 driven and rotated by a first motor 2 is movably supported in the frame 1, and a rotor 3 is sleeved on the shaft body of the main shaft 21, On the outer wall of the rotor 3, there are a number of claws 4 spirally arranged in the axial direction, and a roller 5 is sleeved at an interval outside the rotor 3, and the roller 5 is movably supported in the frame 1 through a support assembly. There are also a number of claws 4 arranged in a spiral direction, and the drum 5 is driven by the second motor 6 in the opposite direction to the rotation of the rotor 3, so that the rotor 3 and the drum 5 can form a shredded film that can be cut and shredded and transported backwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com