Three-degree-of-freedom parallel attitude-adjusting and vibration-isolating platform comprising tower-shaped telescopic branches

A technology of vibration isolation platform and degree of freedom, applied in the direction of workbench, manipulator, program control manipulator, etc., can solve the problems of small working space, large space for attitude adjustment, poor bearing capacity, etc., so as to reduce the driving load and improve the bearing capacity , the effect of reducing the occupied volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

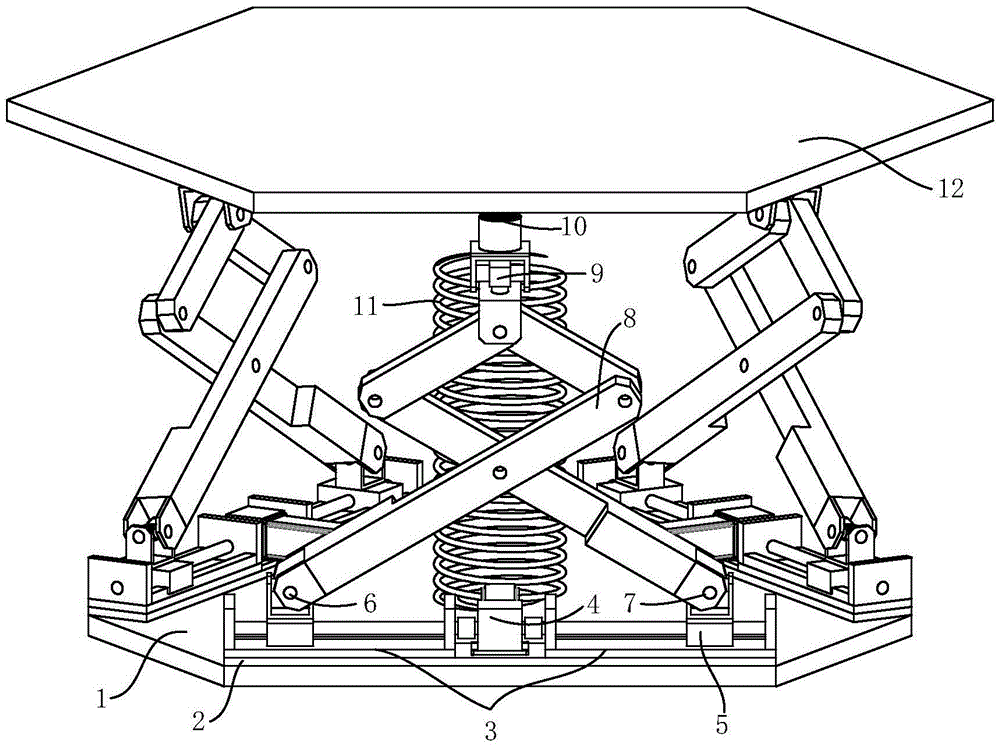

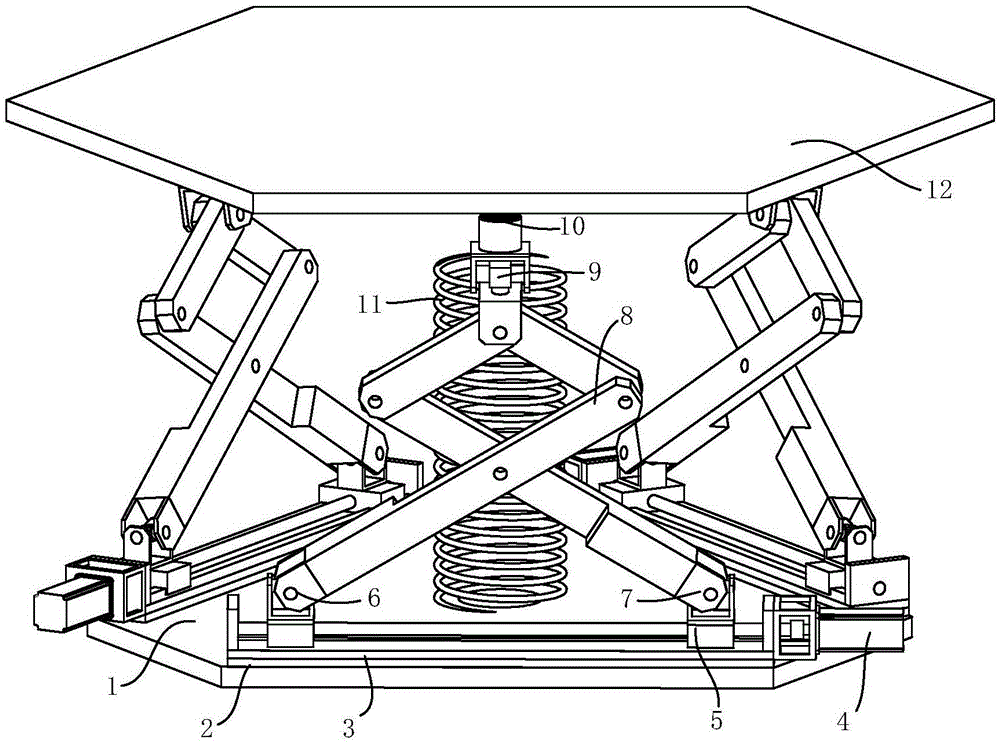

[0029] exist figure 1 In the schematic diagram of the three-degree-of-freedom parallel attitude-adjusting vibration isolation platform with tower-shaped telescopic branches shown, three mounting bases 2 with rectangular cross-sections are evenly fixed on the base 1, and the dual linear modules 3 of each linear drive unit It is fixed on the mounting base, and the sliding center lines of the two sliders 5 of the double linear module are collinear, and the output shaft end of the drive motor 4 is connected with the input shaft end of the double linear module; three tower-shaped telescopic branches with the same structure 8 is composed of two closed-loop connecting rods and a plane scissors mechanism. The scissors shaft of the plane scissors mechanism divides the scissors connecting rod into two parts, the lower part is long and the upper part is short. The short ends of the connecting rods are connected, and the other ends are connected together by a rotating pair. The upper part...

Embodiment 2

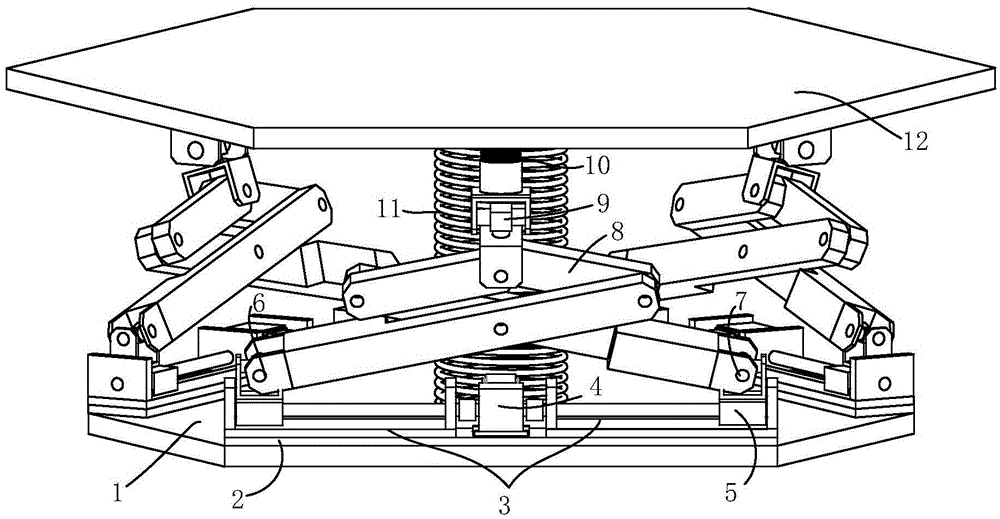

[0032] Such as image 3 As shown, the double linear module 3 is fixedly connected to the mounting base, and the sliding centerlines of the two sliders of the double linear module are collinear. The end is connected with the input shaft end of the dual linear module. Other components and connections are the same as in Embodiment 1.

Embodiment 3

[0034] Such as Figure 4 As shown, three mounting bases 2 with isosceles trapezoidal section are evenly fixed on the base 1, and the double linear modules 3 of each set of linear drive units are fixed on the two slopes of the same mounting base, and the double linear modules The sliding center lines of the two sliders are in the same plane. Other components and connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com