Advancing device for generating a secondary advancing movement of a tool

A feed movement and progressive technology, applied in honing tools, manufacturing tools, metal processing, etc., can solve the problem of too expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

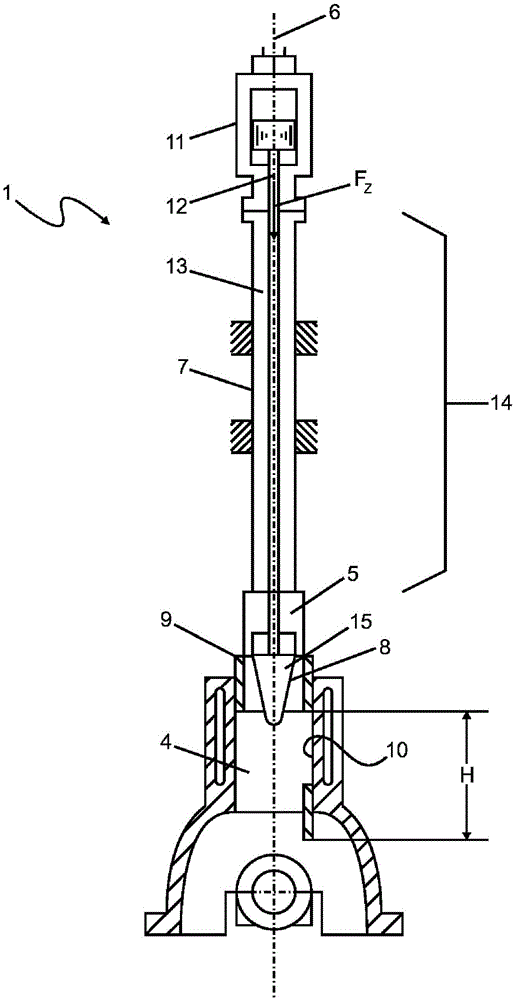

[0037] figure 1A prior art honing device 1 is shown. The honing device 1 produces a cylindrical bore 4 with a rotationally driven honing tool 5 in a known manner, wherein the honing tool 5 performs an oscillating lift movement in addition to the rotational movement.

[0038] The honing tool 5 is thus connected to a spindle 7 which is part of a not shown honing machine and which can be moved back and forth in the direction of the longitudinal axis of the bore or the inner surface 10 to be machined by eg hydraulic or electric lift drives. Furthermore, the spindle 7 is driven in rotation about its longitudinal axis 6 by a rotary drive (not shown) in a known manner. The honing tool 5 carries a machining tool 9 embodied as a honing stone, which can be fed radially outward from a hydraulically actuated feed and can be pressed against the inner surface 10 of the conical bore 4 . The feed device can also be actuated electrically via servomotors, for example. The hydraulic actuation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com