Obtaining a juice of fresh plants by thermomechanical treatment and cosmetic and therapeutic use thereof

A technology of deformation heat treatment and plants, which is applied in cosmetics, cosmetic preparations, and medical raw materials derived from angiosperm subphylum, and can solve problems such as no mention of deformation heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

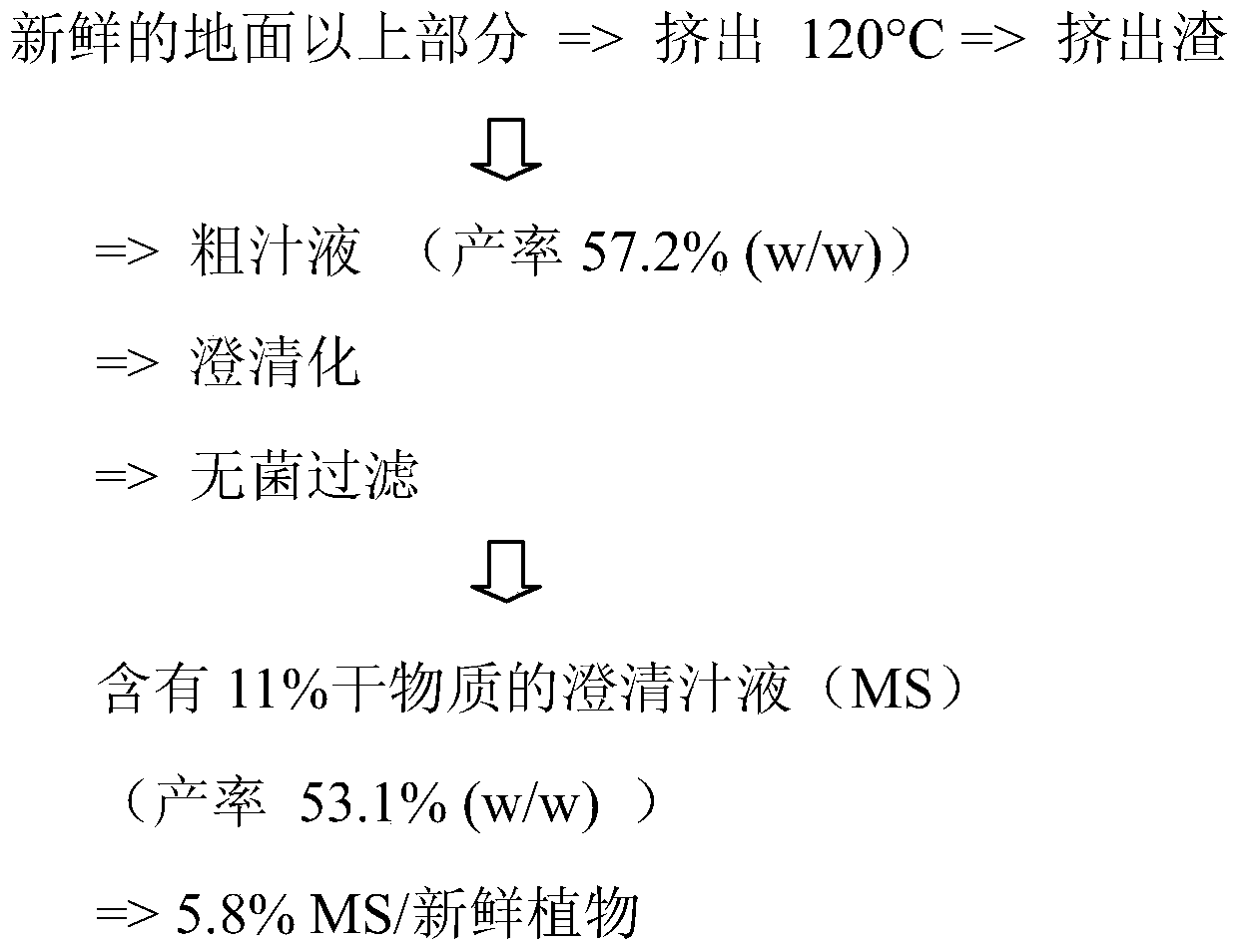

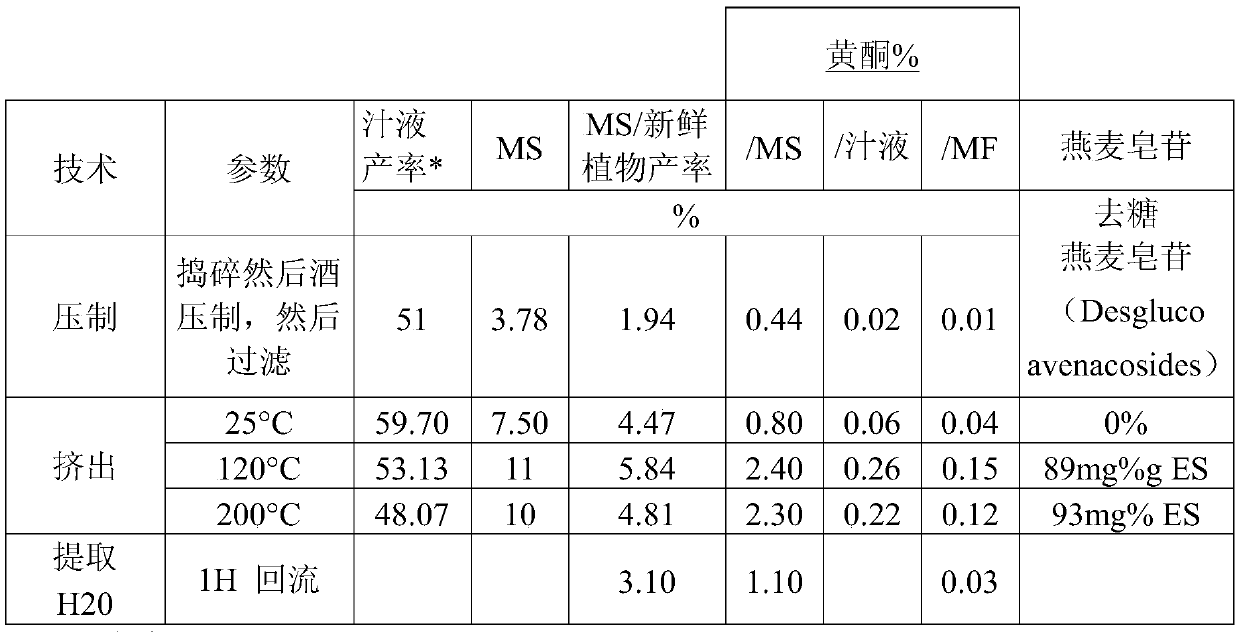

[0087] After a growth period of 2 months (oat seedlings), 12.75 kg of unfrozen (24 h at 2° C.) fresh above-ground parts of oats (Avenasativa L.) harvested by a harvester were fed into a machine with co-rotating, The first barrel of the five-barrel twin-screw extruder with osmotic screws—CLEXTRAL BC45. The temperature applied to different barrels is 30°C / 120°C / 120°C / 120°C / 60°C.

[0088] The protocol of the method is as follows (total duration of extrusion steps = 20 min; treatment rate: 38 kg plants / hour and 22 kg juice / hour)

[0089]

[0090] After extrusion, 57.2% juice w / w relative to the starting material was obtained. Then, clarification and filtration steps were carried out to obtain clarified juice with a final juice yield of 53.1% containing 11% dry matter, ie a yield of extracted dry matter of 5.8% (w / w).

[0091] The juice yield by pressing (mash-press-filter) the same raw material was 50% with 4.5% dry matter, ie a yield of 2.25% (w / w).

[0092] Thus, the extru...

Embodiment 2

[0098] 3.14 kg of unfrozen (18 h at 2 °C) corolla of fresh Echinacea purpurea (Echinacea purpurea (L.) Moench) was fed into a five-barrel twin-screw extrusion with co-rotating, co-rotating osmotic screws Machine—the first barrel of CLEXTRALBC45. The temperature applied to different barrels is 100°C / 100°C / 100°C / 100°C / 60°C. The process and mass balance are given in the table below (total time of extrusion step: 25 minutes; treatment rate: 7 kg plant / hour and 3 kg juice / hour):

[0099] Material Balance

process

dry matter

100

fresh plants

48.1

extrude

16.20%

7 --> 26.9

clarification

10.81%

25

to filter

10.09%

[0100] Thus, after extrusion we obtained 48.1% juice w / w relative to the starting material. Clarification and filtration steps were then performed to obtain clarified juice with a final juice yield of 25% containing 10.09% dry matter, ie a yield of 2.5% (w / w) dry matter.

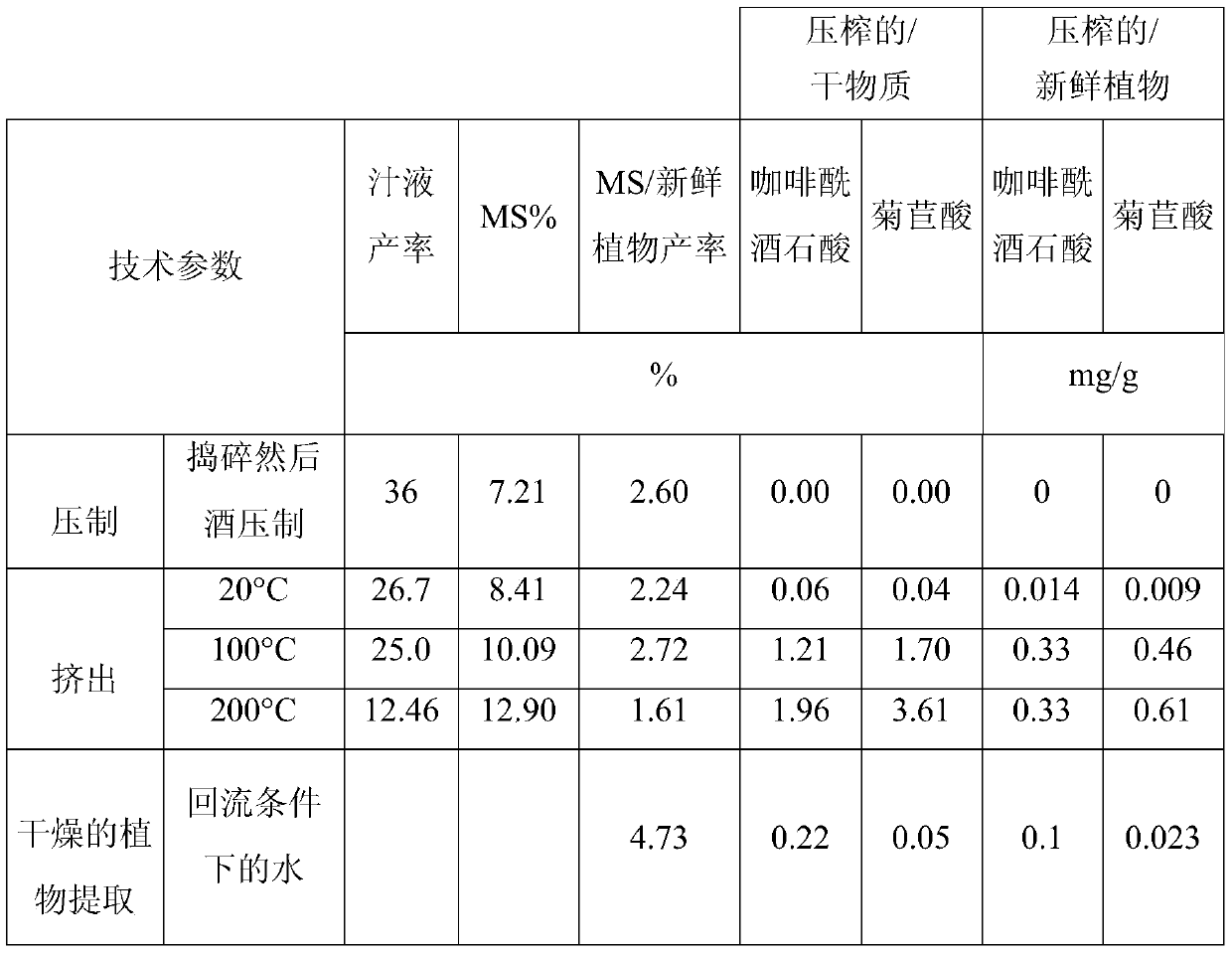

[0101] The ca...

Embodiment 3

[0111] 5.11 kg of unfrozen (20 h at 2° C.) fresh, above-ground parts of lemon balm (Melissaoficinalis L.) were fed into a five-barrel twin-screw extrusion with co-rotating and co-rotating osmotic screws Machine—the first barrel of CLEXTRALBC45. The temperature applied to different barrels is 120°C / 120°C / 120°C / 120°C / 60°C. The process and mass balance are given in the table below (total duration of the extrusion step: 7 minutes; treatment rate: 46 kg plant / hour and 29 kg juice / hour):

[0112]

[0113] Under these conditions, extrusion allowed to obtain a juice with a yield close to 50% and with a dry matter content of 6.5%. In particular, this substance contains rosmarinic acid, which is usually extracted by a hydroalcoholic mixture, such as 70% ethanol). The content of rosmarinic acid in the dry matter extracted by extrusion without any organic solvent was 2.4% (w / w), ie comparable to 70% ethanol extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com