Linear vibration motor

A linear vibration and motor technology, applied in electromechanical devices, electrical components, etc., can solve the problems of small size and weight of mass blocks, reduce the low frequency performance of the motor, restrict the overall performance of the motor, etc., so as to increase the mass, improve the low frequency performance, and save vibration. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

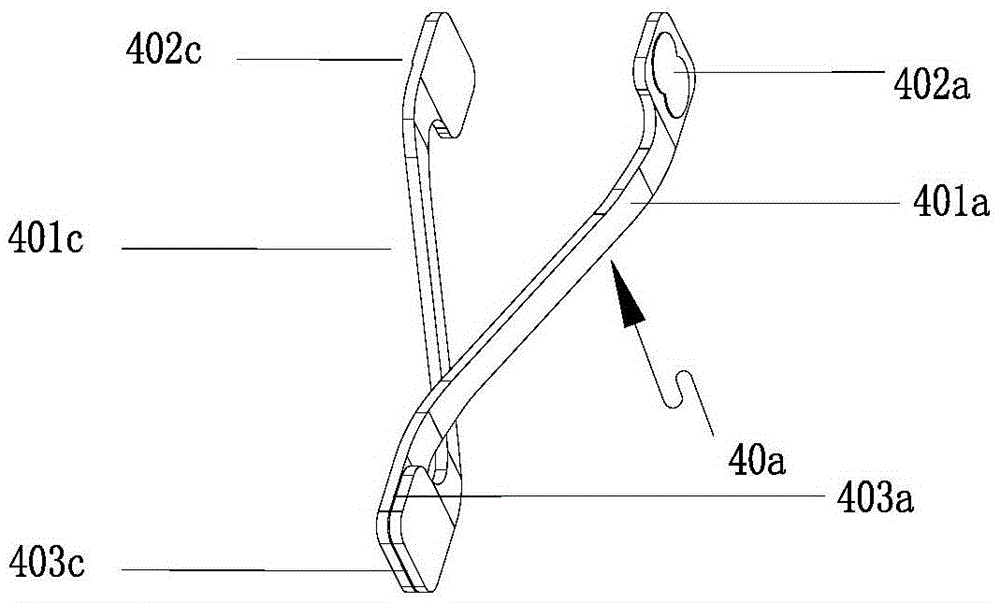

[0036] like Figure 5 and Figure 6 Commonly shown, a linear vibration motor is a cuboid structure, including a housing, a stator, a vibrator 20 and elastic supports 40a located at both ends of the vibrator 20 for supporting the vibrator and providing elastic restoring force. The housing includes an upper shell 10 and a lower shell 12 combined together, the upper shell 10 is a box-like structure with one end open, the lower shell 12 is a plate-like structure, and the open end of the upper shell 10 is buckled on the lower shell 12 , the stator is fixed on the lower case 12, and the vibrator 20 is suspended in the space enclosed by the upper case 10 and the lower case 12 through the elastic support member 40a.

[0037] like Figure 5 and Figure 6As shown together, the vibrator 20 includes a mass block 24. Two installation cavities are arranged side by side at the center of the mass block 24. A permanent magnet 26 is fixed in each installation cavity. The side of the mass blo...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, the difference is that:

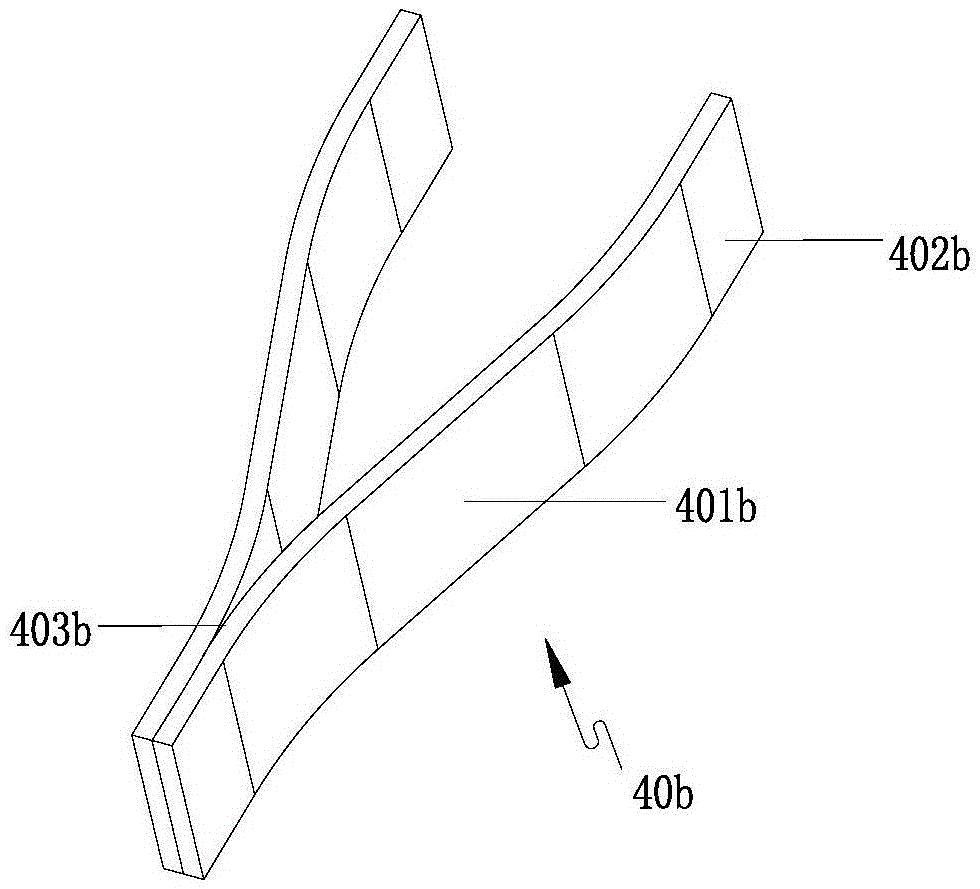

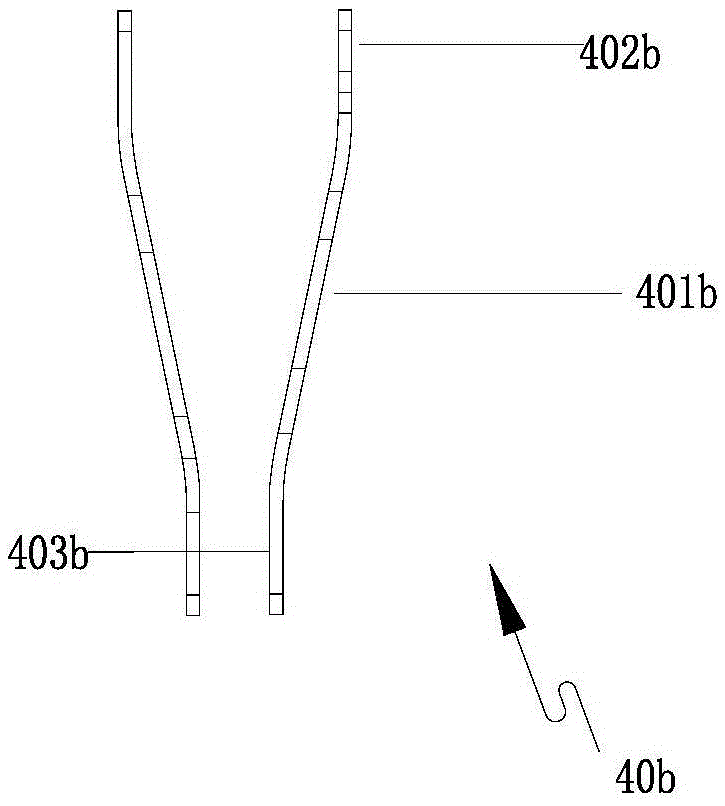

[0049] Such as Figure 7 , Figure 8 and Figure 9 As shown together, two elastic supports 40a are provided at both ends of the vibrator. The two elastic supports 40a have the same structure and are stacked up and down. One elastic support 40a of the two elastic supports 40a located at the same end of the vibrator The state is the state after the other elastic support member 40a is flipped 180° around the central axis, which is the central axis parallel to the vibration direction of the vibrator.

[0050] Such as Figure 7 As shown, three installation cavities are arranged side by side in the middle of the mass block 24 in this embodiment, and a permanent magnet 26 is fixed in each installation cavity. The stator of this embodiment includes two coils 30 arranged side by side, and the two coils 30 are fixed inside the lower case 12 through one FPCB 50 .

[0051] Compared with Example 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com