Method for separating roxarsone and its degradation product in broiler manure

A separation method and technology for degradation products are applied in the field of separation of roxarsone and its degradation products in broiler manure, and can solve the problems of low recovery rate of roxarsone, inability to use inorganic phosphate solution, unsatisfactory effect, etc. The effect of high recovery rate, improved recovery rate, and reduced background interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

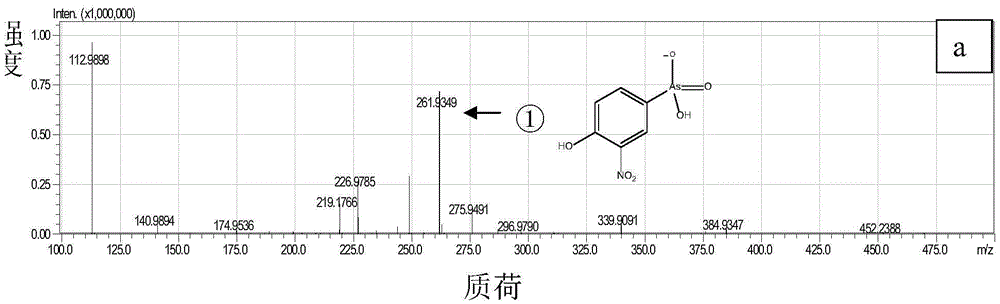

Image

Examples

Embodiment 1

[0032] Example 1 Roxarsone recovery test in broiler manure sample

[0033] 1) Fecal sample pretreatment:

[0034] Accurately weigh 0.50 g of freeze-dried broiler feces samples into a 50 mL polypropylene centrifuge tube, add 30.0 mL of methanol / water (1:9, v / v) solution, ultrasonicate at room temperature for 30 min, shake continuously, and then After centrifugation for 30 min, 1 mL of the supernatant was purified with a WaterOasisMax solid-phase extraction cartridge.

[0035] 2) Sample concentration and purification:

[0036] Fix the solid-phase extraction cartridge, and activate the solid-phase extraction cartridge with 1.0 mL of methanol and 1.0 mL of ultrapure water. After activation, add 1.0mL extraction supernatant, then wash the column with 1mL eluent (0.05mol / L sodium acetate / methanol, 95:5, v / v, pH adjusted to 7), wash the column with 1mL after rinsing Eluate (formic acid / methanol / water, 5:75:20, v / v, pH adjusted to 2) was eluted at a flow rate of 1.0mL / min, and the ...

Embodiment 2

[0043] The influence of embodiment 2 extracting liquid on extraction rate

[0044] According to the steps of Example 1, broiler feces samples were extracted with different extracts to compare the extraction efficiencies of different extracts. The composition of each extract is shown in Table 2.

[0045] According to the method of Example 1, the broiler feces samples added with 10 μg of roxarsone were extracted with different extracts, the concentration of roxarsone in the extraction supernatant was measured, the extraction rate was calculated, and each sample was repeated five times. The results are shown in Table 3:

[0046] Table 2 Composition of extracts from different experimental groups

[0047]

[0048] Table 3 Effects of different extracts on the extraction rate of samples added with 10 μg roxarsone (ROX)

[0049]

[0050] The results show that the volume ratio of the extraction solution used in the present invention is methanol / water with a volume ratio of 1:9,...

Embodiment 3

[0051] The impact of embodiment 3 eluent on recovery rate

[0052] According to the steps of Example 1, broiler feces samples were extracted with methanol / water at a volume ratio of 1:9, and then 1 mL of the supernatant was purified with a WaterOasisMax solid-phase extraction cartridge to compare eluents with different compositions and pH values The influence on the recovery rate of exogenous roxarsone, the composition and pH value of each eluent are shown in Table 4.

[0053] According to the method of Example 1, the broiler feces samples added with 10 μg of roxarsine were extracted, and then according to the method of Example 1, the extraction supernatant was purified with a solid phase extraction column, and the elution with different compositions and pH values was used. The roxarsone was eluted with liquid, and the concentration of roxarsone in the eluent was measured, and the recovery rate was calculated. Each sample was repeated five times, and the results were shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com