Sealing pressure measurement method for vibration damper

A measurement method and shock absorber technology, which is applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of high sealing pressure, inability to fix the axial direction of the shock absorber, and affecting the degree of axial fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

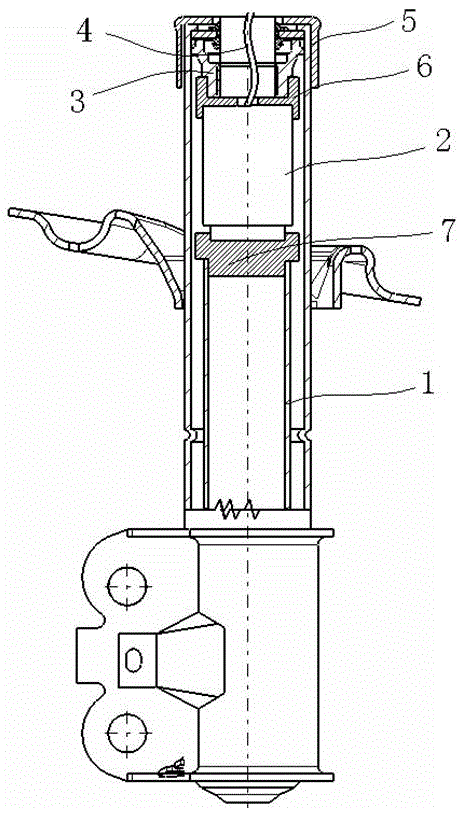

[0018] As shown in the figure, the method for measuring the sealing pressure of the shock absorber in this embodiment includes the following steps: sawing off the working cylinder of the shock absorber into two parts, the upper part and the lower part of the cylinder, and making the top surface of the lower part of the cylinder 1 flush, Take the lower cylinder 1 for testing; put a pressure sensor 2 between the guide 3 of the shock absorber and the lower cylinder 1, so that the assembled length of the guide 3, the pressure sensor 2, and the lower cylinder 1 and It is equal to the sum of the lengths of the original working cylinder and the guide 3, and makes the central axis of the pressure sensor 2 coincide with the central axis of the lower cylinder 1; on the premise that the piston rod is not installed, connect the wire harness 4 of the pressure sensor 2 from the piston rod hole Lead out of the shock absorber and connect with the force value display (not shown in the figure); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com