In-bore plasma armature parameter real-time in-situ measurement method

A plasma and in-situ measurement technology, applied in the field of ion parameter measurement, can solve the problems of inability to measure the moving speed of the plasma armature and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

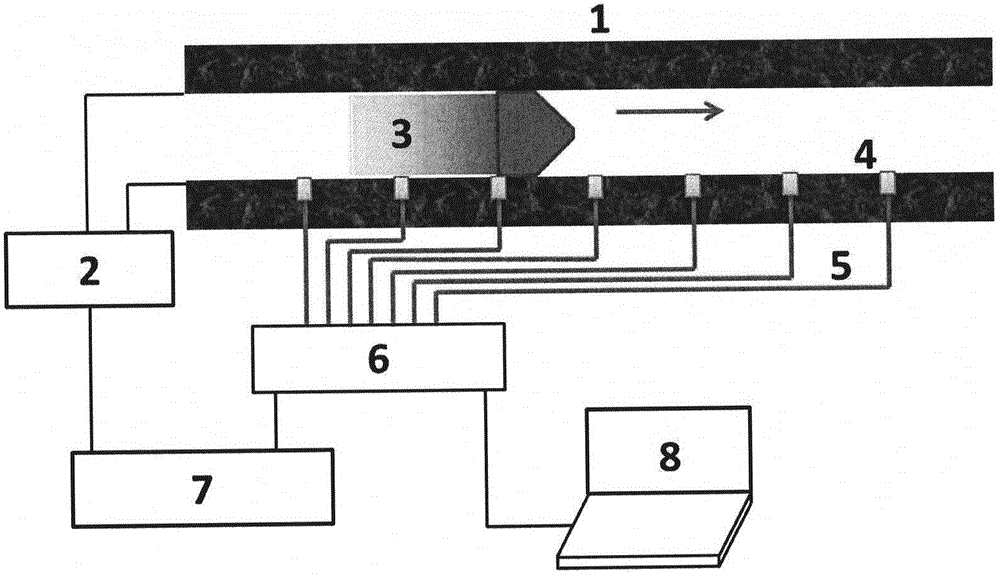

[0075] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0076] An embodiment of the present invention provides a method for real-time in-situ measurement of plasma armature parameters in a bore, the method comprising the following steps:

[0077] Step 1: Embedding a quartz window in the inner wall of the electromagnetic railgun bore;

[0078] There are 7 quartz windows embedded in the inner wall of the electromagnetic railgun bore. The track of the electromagnetic railgun bore is 1.6 meters long, and a quartz window is embedded at an interval of 0.2 meters.

[0079] Step 2: generation of emission spectrum;

[0080] A 24kV pulse power supply is used to discharge the polyethylene liner to generate a plasma armature 3 for electromagnetic rail launch, and the plasma armature 3 moves rapidly in the inner wall 1 of the electromagnetic rail gun bore.

[0081] Step 3: Obtain the spectrum emitted by the plasma armature; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com