Method for measuring pull-press and bending composite deformation field of variable cross section beam structure

A variable cross-section beam, bending deformation technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of easy deformation of datum, difficulty in establishing datum, and limited measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

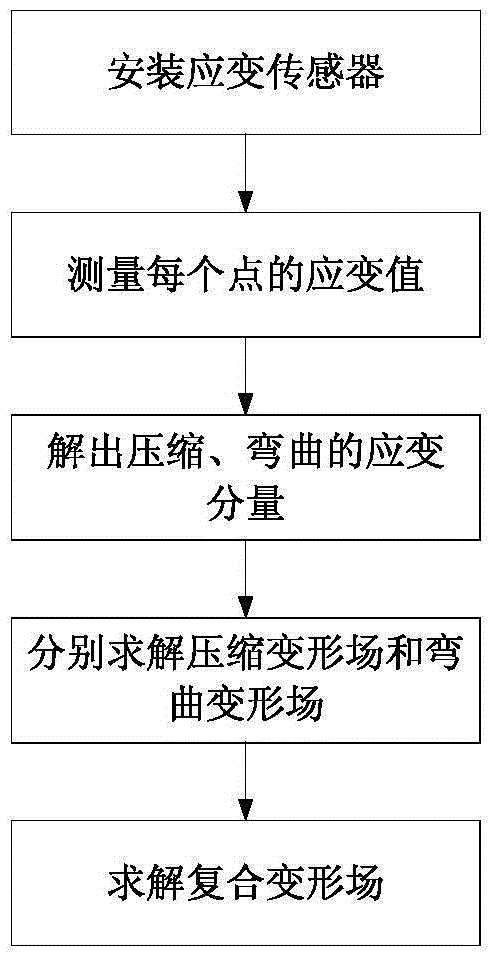

Method used

Image

Examples

Embodiment 2

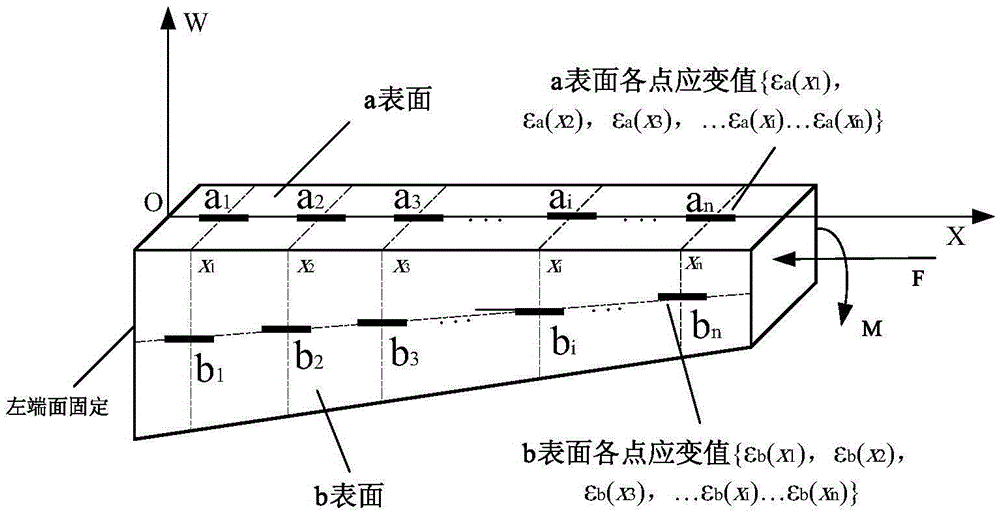

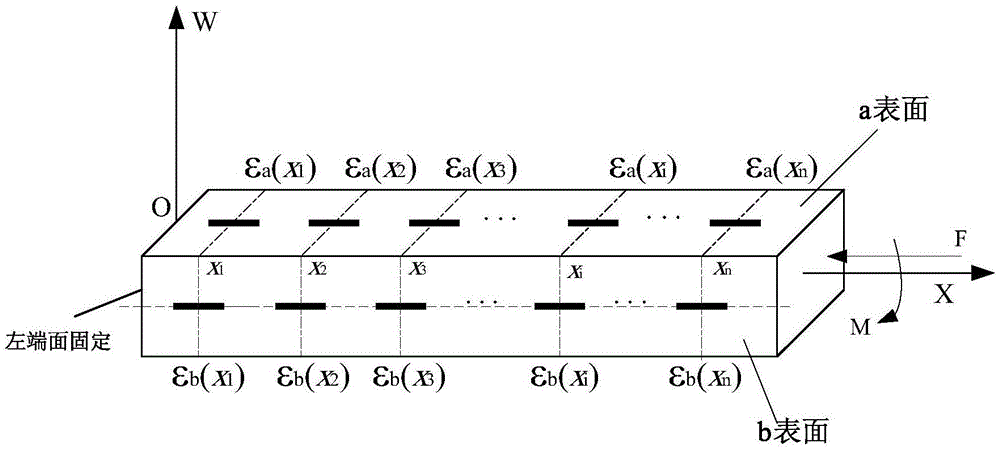

[0028] In the second embodiment, when measuring the deformation of the variable-section column of the machine tool, after the variable-section column of the machine tool is subjected to tensile compression deformation and bending deformation at the same time, the selected measurement surface is as follows Figure 5 shown.

[0029] Among them, the first step is to install the displacement sensor on the surface of the variable-section column of the machine tool. First, a rectangular coordinate system must be established on the plane where the variable-section beam structure bends, and the vertical direction is taken as the x-axis, as shown in Figure 5 As shown, a w-axis is established at one end of the beam perpendicular to the x-axis (ie, the bending direction); Layer positions correspond to the same number of strain sensors installed, which are denoted as {a 1 , a 2 , a i ,...a n} and {b 1 , b 2 , b i ,... b n}, where {a 1 , a 2 , a i ,...a n} means to install {x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com