An automatic mold ejection device for an extension body and an automatic mold splitting machine for preloading an extension body

A delayed and automatic discharge technology, applied in the direction of weapon accessories, ammunition, offensive equipment, etc., can solve unexplained problems, achieve the effects of avoiding contact, good safety performance, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

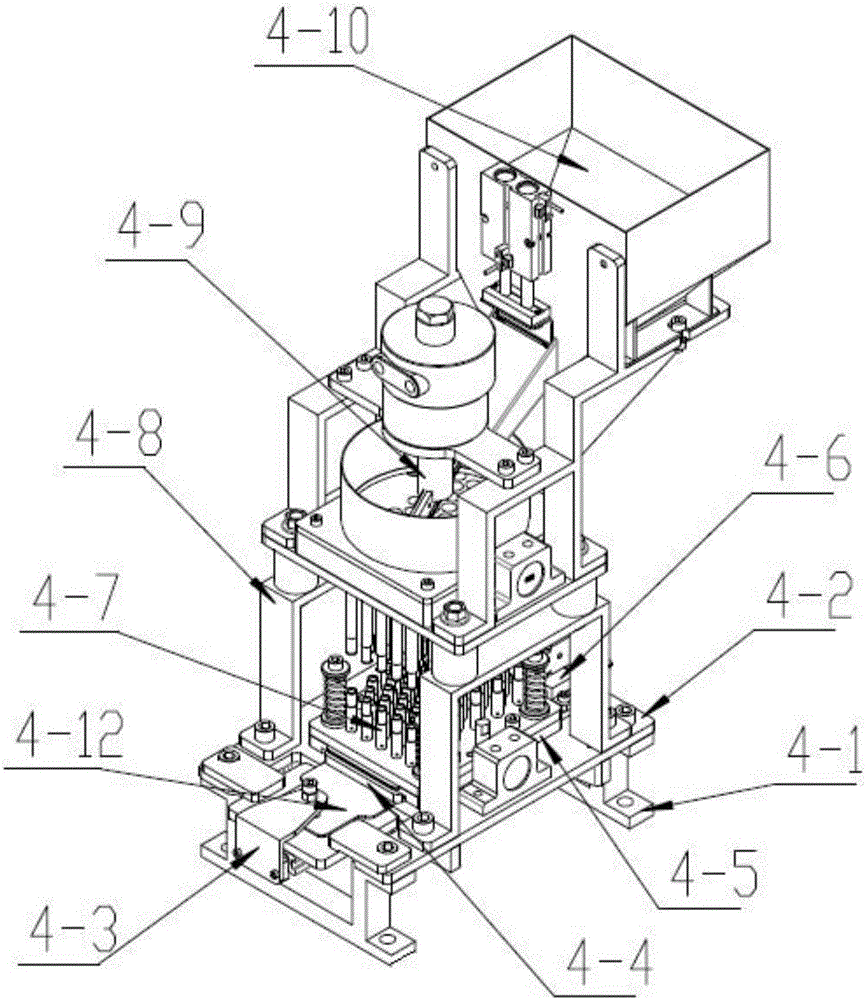

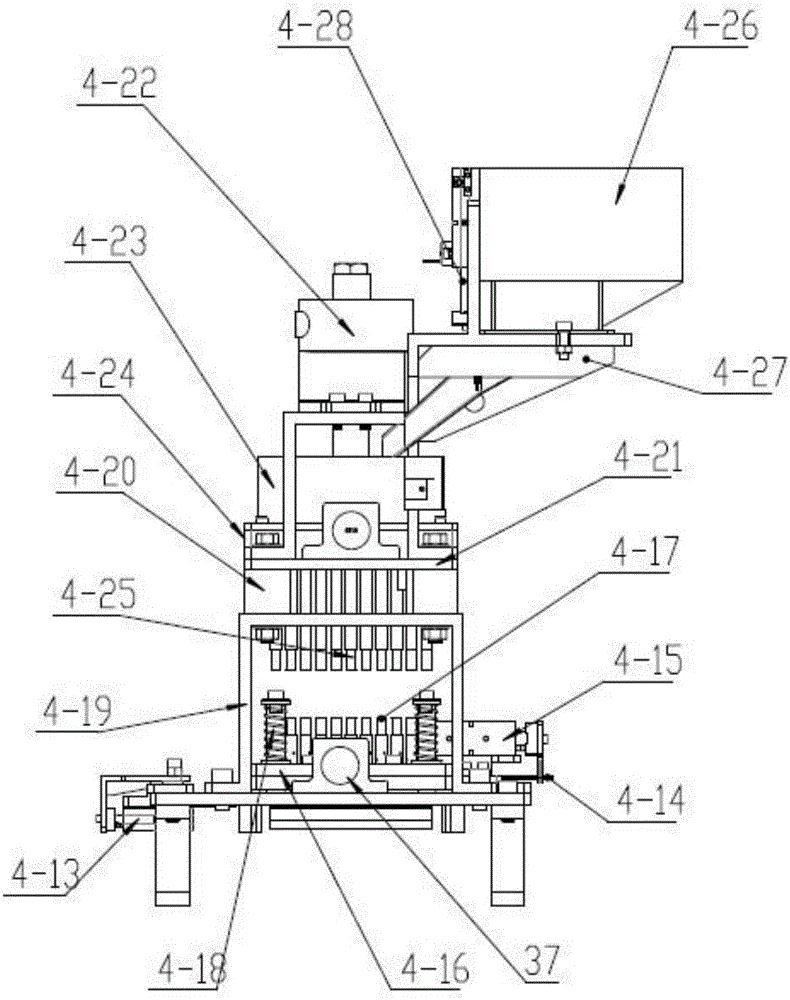

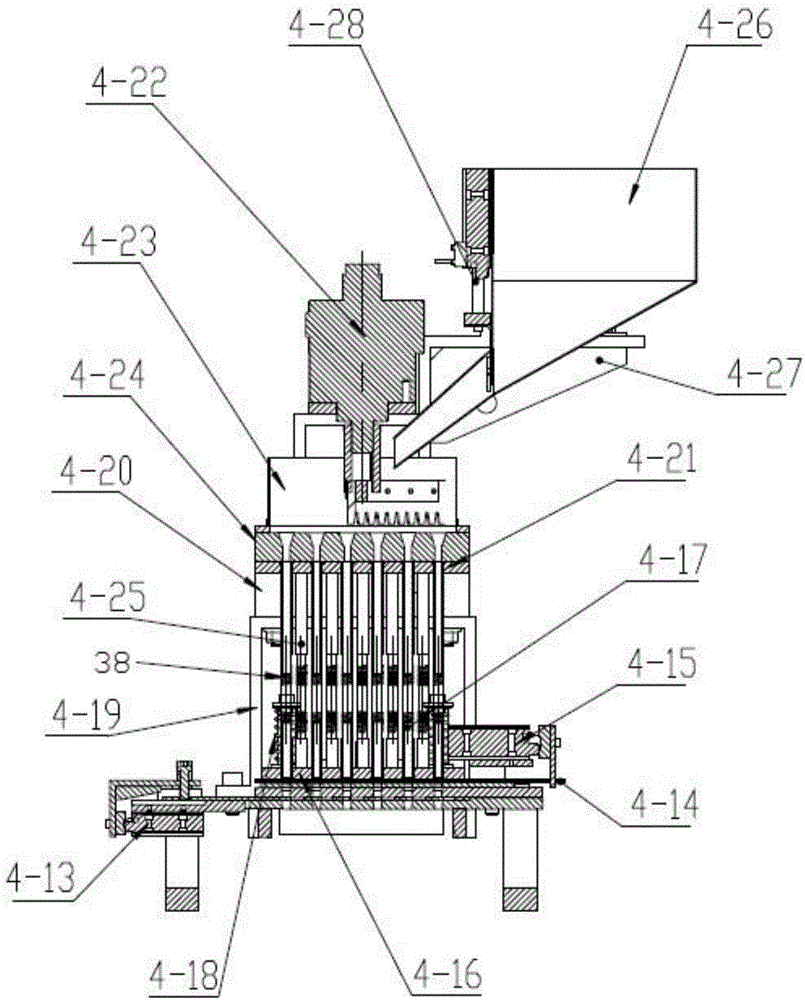

[0043] see Figure 1 ~ Figure 4 An automatic mold ejection device for delayed bodies, including a bottom support 4-1 fixed on the workbench 1, and a temporary medicine hopper assembly 4 fixed on the bottom support 4-1 for storing and discharging the delayed bodies -10. The automatic drug discharge assembly 4-9 fixed on the bottom support 4-1, the temporary medicine hopper assembly 4-10 includes the bucket seat frame 4-27 fixed on the bottom support, and the bucket seat frame 4 fixed on the bottom support The temporary medicine hopper 4-26 on the -27, the automatic drug discharge assembly 4-9 includes a circular bucket 4-23, an air motor (stirring device) 4-23 for connecting the delay body discharged by the temporary medicine hopper 4-26 22. The drug leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com