Safety trip device for fracturing string

A fracturing pipe string and disconnecting device technology, applied in drilling pipe, casing, production fluid, etc., can solve the problems of complicated construction, long workover time, and high workover cost, reduce the workload of operation, and achieve significant economic benefits. Benefit and low workover cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

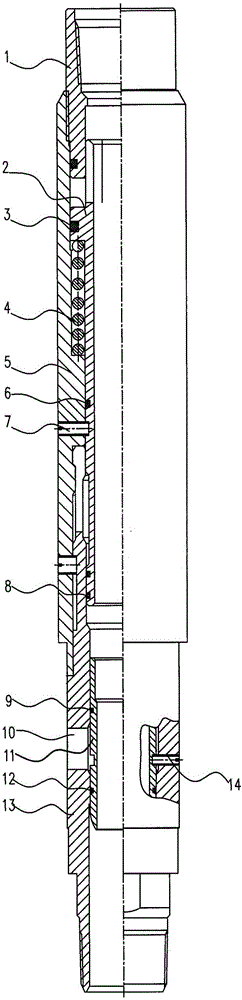

[0007] Attached below figure 1 Embodiments of the present invention will be described.

[0008] As can be seen from the figure, the embodiment of the present invention includes an upper joint 1, a locking sleeve 2, an upper sealing ring 3, a spring 4, an outer suspension tube 5, a middle sealing ring 6, a locking nail 7, a lower sealing ring 8, and an upper sealing ring of a sliding sleeve 9. Sliding sleeve 11, sliding sleeve lower sealing ring 12, inner suspension pipe 13, sliding sleeve shear nails 14, the upper part of the inner suspension pipe 13 is milled into a strip body, and the strip body is suspended in the suspension inside the outer suspension pipe 5 On the shoulder, the suspension shoulder is a conical surface, which can generate radial component force. The upper sealing ring 3, the middle sealing ring 6, and the lower sealing ring 8 are installed on the lock sleeve, and the spring 4 is set on the lock sleeve 2. The lock sleeve 2 is put into the outer suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com