A construction method of water pressure jet flushing well formation for downfall tube wells

A construction method and technology of downpipes, which are applied in infrastructure engineering, liquid/gas jet drilling, construction, etc., can solve the problems of large equipment, large amount of engineering, economic efficiency and poor precipitation effect, etc., to achieve flexible construction, The effect of improving construction efficiency and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

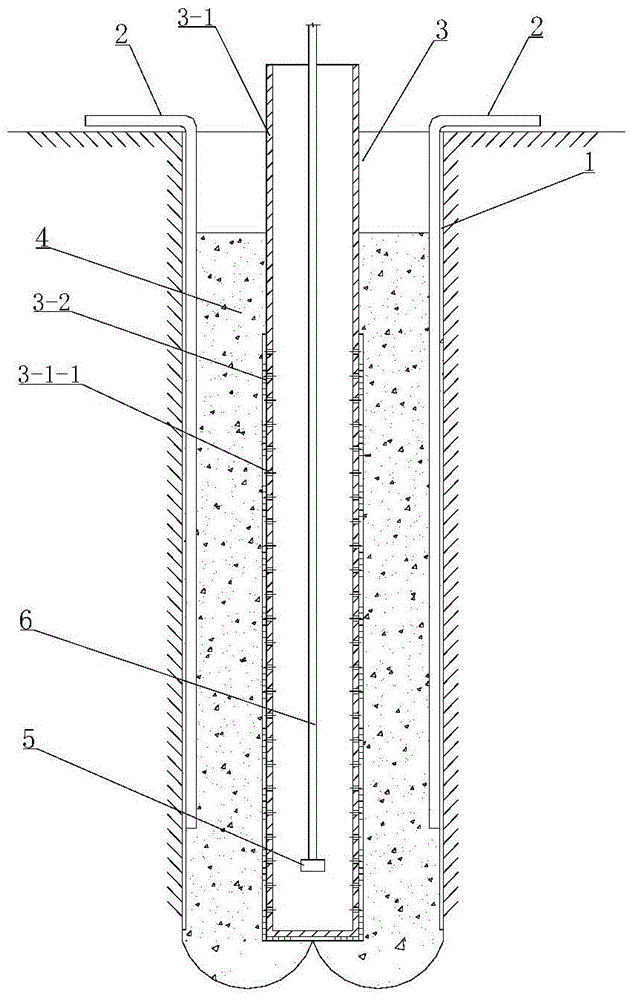

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0034] see figure 1 with 2 The invention discloses a hydraulic jetting type well-forming construction method of a downcomer well, comprising the following construction steps:

[0035] S1 Well Hole Positioning: Carry out setting-out positioning according to the well position design.

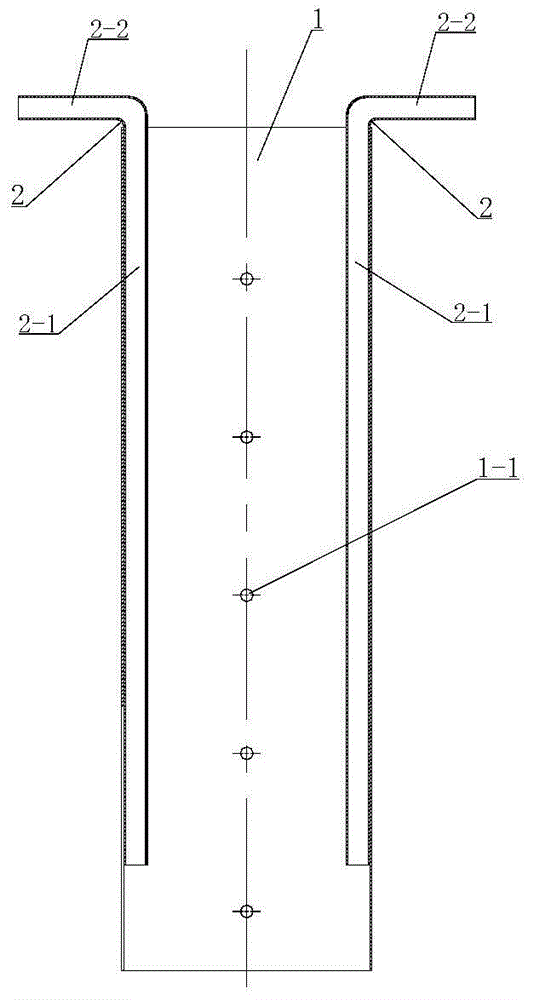

[0036] S2 Making the casing 1 and installing the flushing pipe 2:

[0037] The shape and structure of the casing is as follows: it is closed in the circumferential direction, and the two ends are open. On the side wall of the casing, a plurality of sets of communicating holes are evenly distributed along the circumferential direction. 1-1 structure, the distance between the communication hole at the bottom and the bottom of the casing is 0.15~0.20m;

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com