Super stretchable high-conductivity graphene fiber and preparation method thereof

A graphene fiber, highly conductive technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as limited industrial application, brittleness, etc., to overcome poor stretchability, easy preparation, length and diameter can be adjusted. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

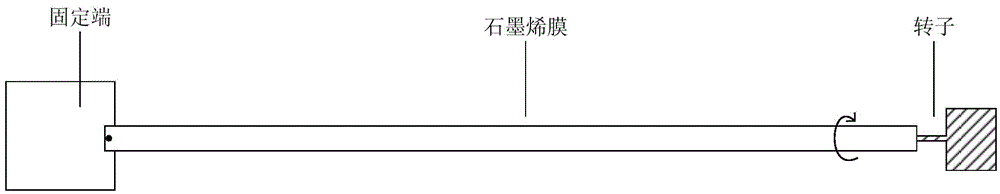

[0020] Such as figure 1 Shown, a kind of super-stretchable highly conductive graphene fiber of the present invention, described fiber is the double Archimedes spiral structure (structure can refer to bibliography BiscrollingNanotubeSheetsandFunctionalGuestsintoYarns) that is made up of graphene sheet layer, and interlamellar spacing is 0.336 nm, the carbon-to-oxygen ratio of the fiber is 57.87, and the XRD diffraction peak position is 26.5°.

[0021] A kind of preparation method of the super-stretchable highly conductive graphene fiber of the present invention, the steps are as follows:

[0022] (1) preparing a graphene oxide film with a thickness of 0.5 to 50 μm;

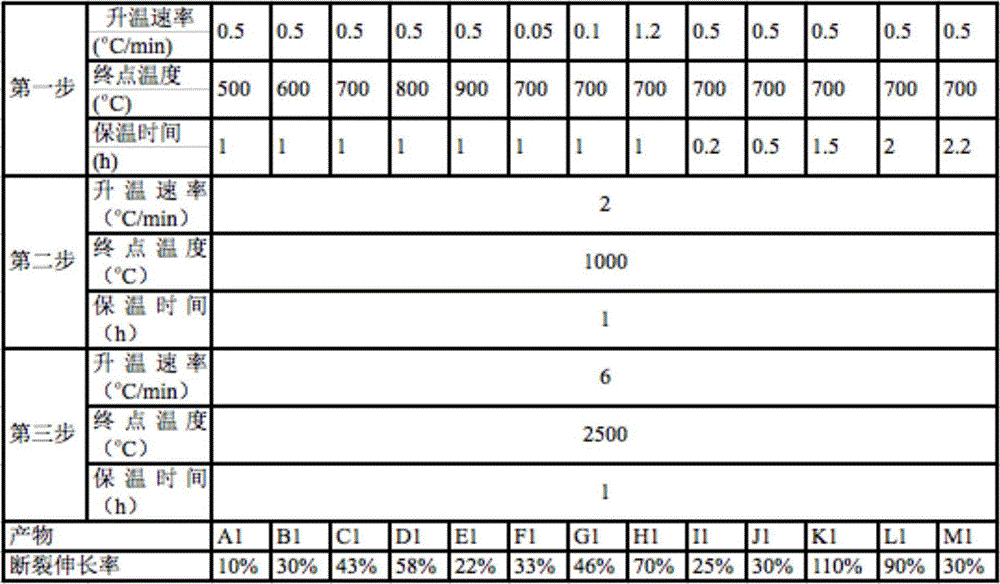

[0023] (2) The graphene oxide film with a thickness of 0.5 to 50 μm prepared in step 1 is heat-treated in the manner shown in Table 1 to Table 3 to obtain a graphene film; under high temperature treatment, the carbon-to-oxygen ratio of graphene increases from 10.19 to 57.87 (tested by X-ray photoelectron spectros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com